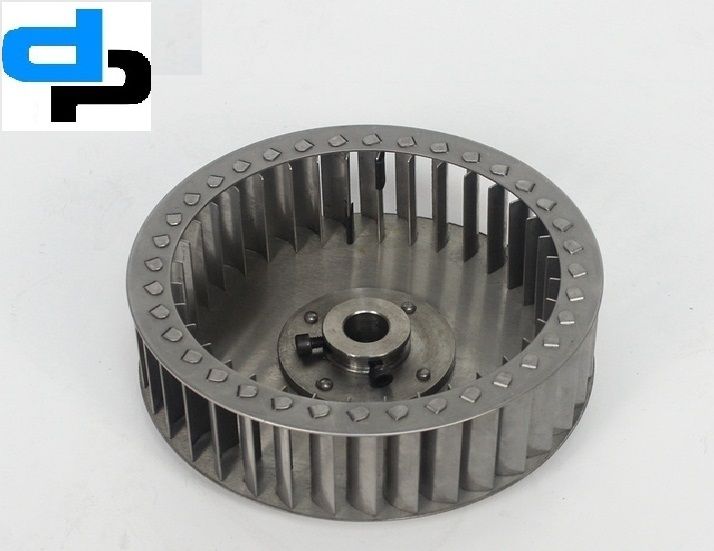

DIDW Centrifugal Fan 250 MM X 203 MM

DIDW Centrifugal Fan 250 MM X 203 MM Specification

- Flow Rate

- 650 CFM

- Motor Power

- 1 HP

- Life Span

- 10-12 Years (under standard operating conditions)

- Output Power

- 0.75 kW

- Power

- 0.75 kW

- Pressure Range

- Up to 60 mmWG

- Max Pressure

- 60 mmWG

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 650 CFM

- Pressure

- Upto 60 mmWG

- Application

- Industrial Ventilation and Exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2880 RPM

- Noise Level

- <75 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- Approx. 15 kg

- Dimension (L*W*H)

- 250MM x 203MM

- Color

- Grey

DIDW Centrifugal Fan 250 MM X 203 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- Jammu and Kashmir, Andaman and Nicobar Islands, South India, East India, West India, Assam, Arunachal Pradesh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Himachal Pradesh, Jharkhand, Kerala, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Karnataka, Madhya Pradesh, North India, Punjab, Bihar, Andhra Pradesh, Central India, Chhattisgarh, All India

About DIDW Centrifugal Fan 250 MM X 203 MM

DIDW Centrifugal Fan 250 MM X 203 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 38 | DP 10 80 | 250 X 203X 210 | 10 X 8 | 12.70 (1/2) & 15 MM | AL. / GI. |

Efficient Air Circulation for Industrial Needs

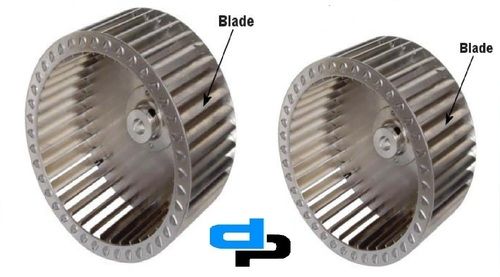

Engineered for applications requiring consistent and reliable airflow, the DIDW Centrifugal Fan is optimal for air handling units, clean rooms, and ventilation systems. Its double inlet/double outlet configuration enhances air movement, making it particularly suitable for large industrial spaces where effective air distribution is critical. The powder-coated finish ensures resistance to environmental wear, while the belt-driven mechanism provides stable performance.

Built for Durability and Longevity

Constructed from high-quality mild steel and protected with a powder-coated finish, this fan is designed to withstand harsh industrial environments. The robust TEFC (Totally Enclosed Fan Cooled) enclosure and ball bearing system minimize maintenance needs, while supporting a long operational life of up to 12 years. Its reliable performance is backed by a three-phase motor delivering up to 1 HP for consistent results.

FAQs of DIDW Centrifugal Fan 250 MM X 203 MM:

Q: How is the DIDW Centrifugal Fan installed and mounted?

A: This centrifugal fan is base-mounted for secure placement, typically installed on a stable surface or framework. Installation should be carried out following the manufacturers instructions by skilled technicians to ensure optimum safety and performance.Q: What applications is this fan suitable for?

A: The fan is ideal for industrial ventilation and exhaust, particularly in air handling units, clean rooms, and large-scale ventilation systems where high airflow and stable pressure are required.Q: When should maintenance be performed on the DIDW Centrifugal Fan?

A: Regular maintenance is recommended depending on operational hours, usually every six months. Key maintenance includes checking the belt tension, cleaning the impeller, and ensuring bearings are lubricated for optimal performance and longevity.Q: Where can this fan be used most effectively?

A: This fan is suitable for industrial environments such as factories, laboratories, clean rooms, and large commercial buildings that require efficient air circulation and ventilation.Q: What is the advantage of a forward-curved, double inlet double width impeller design?

A: The forward-curved, DIDW impeller design allows for greater airflowup to 650 CFMwhile maintaining moderate pressure and low noise levels. This configuration is especially effective for uniform air distribution and energy efficiency in ventilation systems.Q: How does the powder-coated finish benefit the fan?

A: The powder-coated finish enhances the fans resistance to corrosion and environmental factors, extending its operational life and maintaining a professional appearance even in demanding industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 160 MM X 178 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, HVAC, Ventilation, Industrial Air Circulation

Product Type : Others, DIDW (Double Inlet Double Width) Centrifugal Fan

DIDW Centrifugal Fan 250 MM X 254 MM

Price 3000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Industrial Ventilation, HVAC System, Air Cooling

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

DIDW Centrifugal Fan 380 MM X 380 MM

Price 10000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Ventilation, HVAC, Air Handling Units, Industrial & Commercial Air Movement

Product Type : Others, Double Inlet Double Width Centrifugal Fan

DIDW Centrifugal Fan 300 MM X 305 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Ventilation, Air Handling Units, Industrial Exhaust

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS