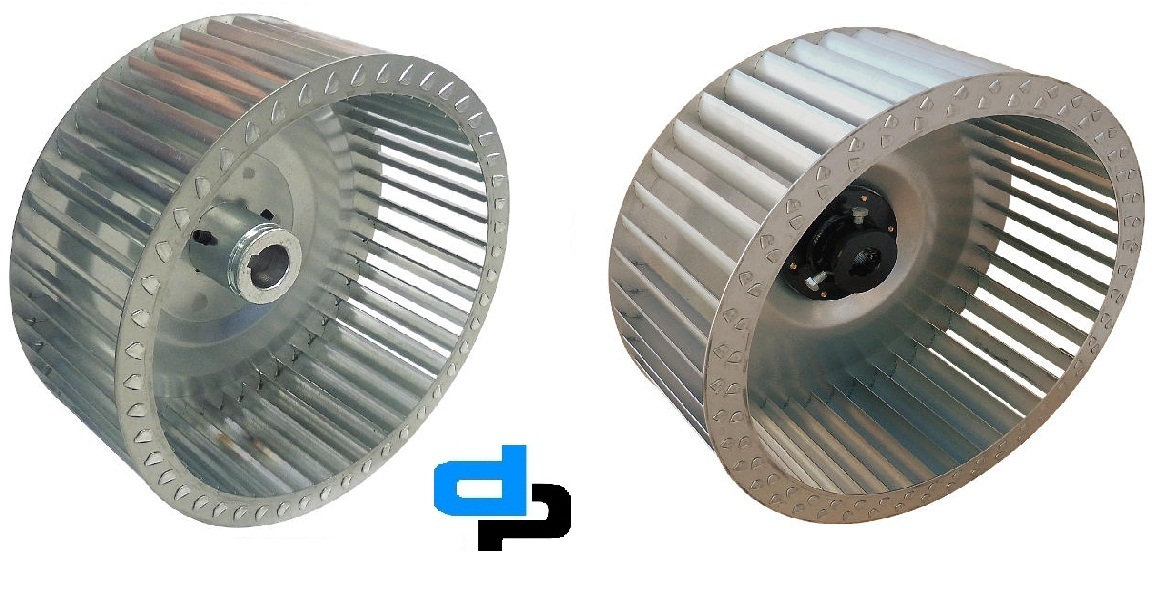

DIDW Centrifugal Fan 530 MM X 530 MM

DIDW Centrifugal Fan 530 MM X 530 MM Specification

- Life Span

- 10-12 Years

- Flow Rate

- 3500-4000 m3/h

- Output Power

- 2.2 kW

- Pressure Range

- 200-300 mm WC

- Max Pressure

- 300 mm WC

- Power

- 3 kW

- Motor Power

- 3 HP

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- Up to 4000 CFM

- Pressure

- 250 mm WC

- Application

- Industrial Air Handling, HVAC, Ventilation, Exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- <78 dB(A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- Approx. 38 kg

- Dimension (L*W*H)

- 530 mm x 530 mm x 650 mm

- Color

- Blue and Silver

DIDW Centrifugal Fan 530 MM X 530 MM Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Tripura, Manipur, South India, Central India, North India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Punjab, Andhra Pradesh, Chhattisgarh, Himachal Pradesh, All India

About DIDW Centrifugal Fan 530 MM X 530 MM

DIDW Centrifugal Fan 530 MM X 530 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 63 | DP 21 21 | 530 X 530 X 430 | 21 X 21 | 35 MM,40 MM,& 1.5'' | AL. / GI. |

Precision Engineering for Industrial Use

This centrifugal fan is purposefully designed for demanding industrial air management requirements, offering reliability and efficiency. The forward curved impeller configuration, belt-driven mechanism, and powder coated mild steel construction ensure robust performance, corrosion resistance, and a long operational life. Its sealed ball bearings and Class F insulated motor deliver sustained durability, while the blue and silver finish gives it a distinct industrial appearance.

Superior Performance and Versatile Applications

With an operational range of -15C to +60C, a pressure range of 200-300 mm WC, and air flows up to 4000 m3/h, this fan meets diverse industrial needs. Its a preferred solution for HVAC systems, ventilation, exhaust, and industrial air handling, ensuring a safe and effective working environment. Despite its powerful output, it maintains a noise level below 78 dB(A), making it well-suited to locations where minimal disturbance is essential.

FAQs of DIDW Centrifugal Fan 530 MM X 530 MM:

Q: How is the DIDW Centrifugal Fan 530 MM X 530 MM typically installed?

A: This fan is designed for base-mounting, making it straightforward to install on stable surfaces in industrial settings. Its rectangular inlet and outlet streamline connection to existing ventilation or duct systems, and it can be configured for various airflow requirements depending on your facilitys layout.Q: What are the main benefits of the forward curved blade impeller in this fan?

A: Forward curved blades are effective for handling large volumes of air at moderate pressure, ensuring efficient air delivery ideal for HVAC, ventilation, and exhaust applications. They help maintain consistent airflow and contribute to the fans low operational noise.Q: When should motor overload protection be used with this fan?

A: Motor overload protection is built into the system, providing essential safety against electrical faults or excessive loading during operation. It automatically activates whenever the motor detects abnormal current draw or thermal overload, protecting the device and enhancing reliability.Q: Where is this centrifugal fan most commonly used in industrial settings?

A: This fan is optimally employed in environments requiring controlled air movement such as manufacturing plants, HVAC systems, warehouses, and industrial ventilation and exhaust setups. It is also well-suited for use in processing facilities where consistent air flow and moderate pressure are necessary.Q: What process is involved in maintaining this centrifugal fan for optimal performance?

A: Routine maintenance includes inspecting and cleaning the impeller, checking belt tension, and ensuring the sealed ball bearings are in good condition. Periodic checks for motor performance and safety device functionality will help maximize the fans lifespan and ensure safe operation.Q: How does the fans powder coated finish provide added value?

A: The powder coated finish protects against corrosion, abrasion, and harsh industrial conditions, thus prolonging the fans life span and maintaining its aesthetic blue and silver appearance even in demanding operational environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 151 MM X 127 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Pressure : Other, Medium

Power : 180 W

Dimension (L*W*H) : 151 mm x 127 mm

Max Pressure : 1300 Pa

DIDW Centrifugal Fan 530 MM X 455 MM

Price 21000.00 INR

Minimum Order Quantity : 1 Piece

Pressure : Other, 380 Pa

Power : 2.2 kW

Dimension (L*W*H) : 530 mm x 455 mm x 510 mm

Max Pressure : 410 Pa

DIDW Centrifugal Fan 100 MM X 100 MM

Price 750 INR

Minimum Order Quantity : 5 Pieces

Pressure : Other, 80 mm WC

Power : 0.25 HP

Dimension (L*W*H) : 100 mm x 100 mm

Max Pressure : 90 mm WC

DIDW Centrifugal Fan 151 MM X 165 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Pressure : Other, 175 Pa

Power : 0.18 kW

Dimension (L*W*H) : 151 mm x 165 mm x 210 mm (approx.)

Max Pressure : 180 Pa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS