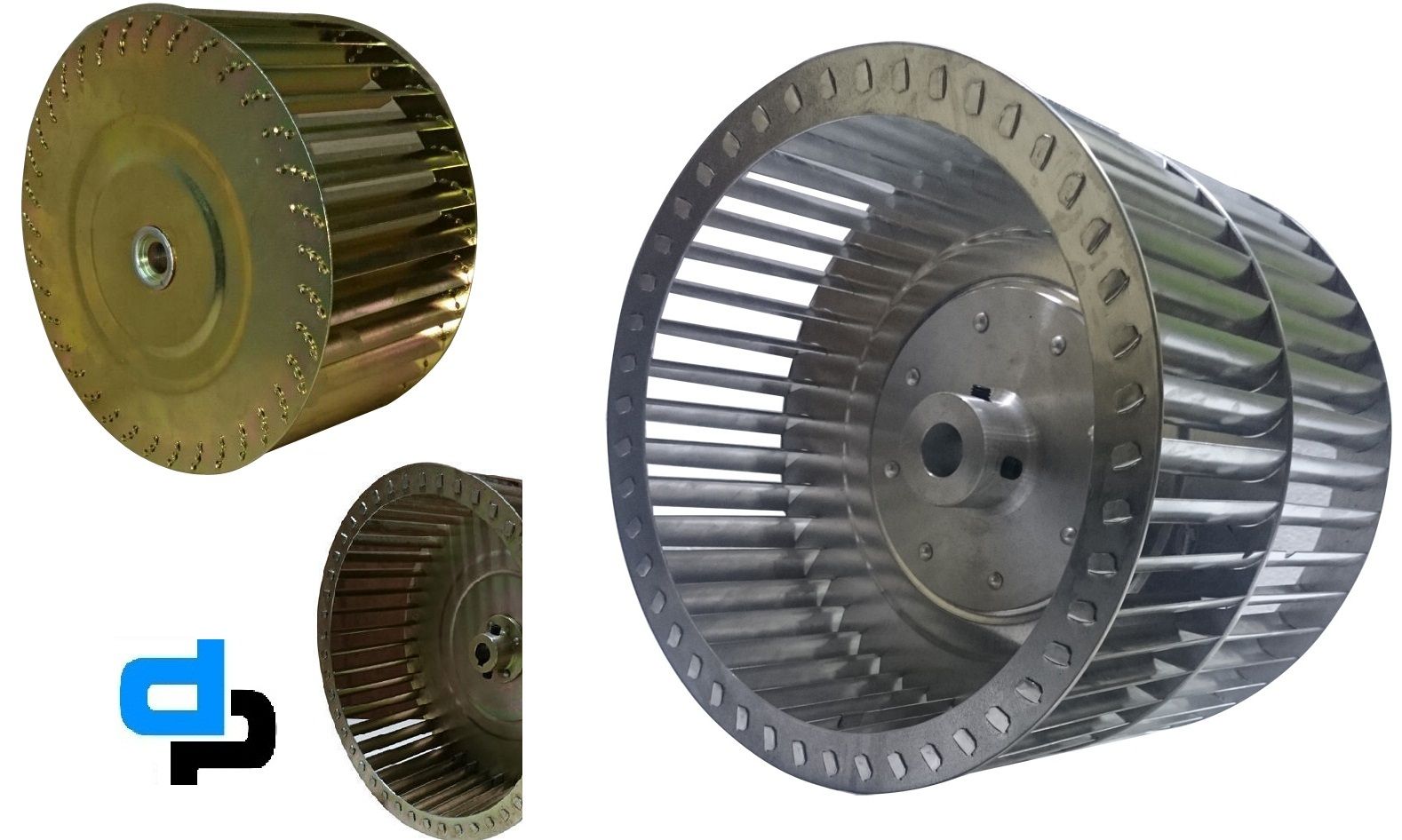

DIDW Centrifugal Fan 160 MM X 178 MM

DIDW Centrifugal Fan 160 MM X 178 MM Specification

- Life Span

- 40,000 hours (Approx)

- Power

- 120 W

- Flow Rate

- 350-550 m/h

- Max Pressure

- 400 Pa

- Motor Power

- 120 W

- Output Power

- 120 W

- Pressure Range

- 250-400 Pa

- Product Type

- DIDW (Double Inlet Double Width) Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- 350-550 m/h

- Pressure

- 250-400 Pa

- Application

- HVAC, Ventilation, Industrial Air Circulation

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 72 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- 3.8 kg (Approx)

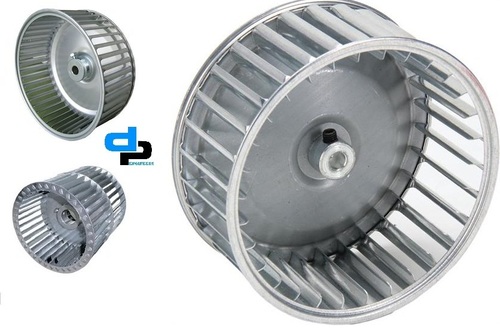

- Dimension (L*W*H)

- 160 mm x 178 mm x 180 mm (Approx)

- Color

- Silver/Grey

DIDW Centrifugal Fan 160 MM X 178 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Nagaland, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Delhi, Gujarat, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

About DIDW Centrifugal Fan 160 MM X 178 MM

DIDW Centrifugal Fan 160 MM X 178 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 13 | DP 65 70 | 160 X 178 X 135 | 6.5 X 7 | 12.70 (1/2'') & 15 MM | AL. / GI. |

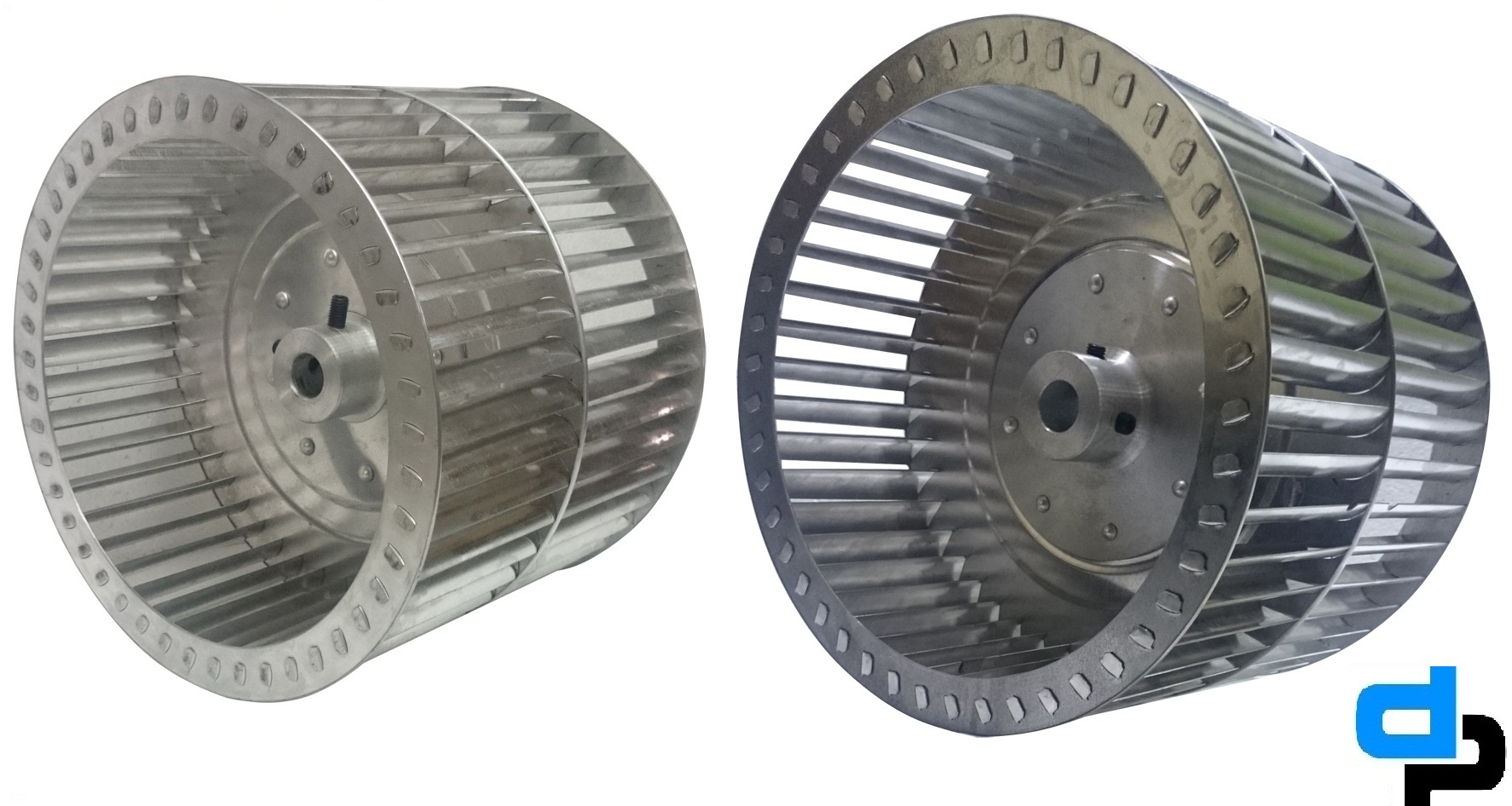

High-Efficiency Air Circulation

The double inlet, forward curved impeller design maximizes airflow capacity while maintaining low noise levels, ensuring efficient ventilation in industrial and commercial spaces. Its compact yet powerful construction is ideal for demanding air movement applications.

Durable and Reliable Construction

Crafted from corrosion-resistant galvanized steel, the DIDW centrifugal fan withstands rigorous environments and offers lasting performance. The IP44 protection and Class B insulation enhance operational safety and longevity.

Versatile Installation and Maintenance

Base mounting simplifies installation, while easy access to serviceable parts like the impeller, bearings, and motor allows for straightforward maintenance and reduced downtime. The terminal box connection expedites electrical setup.

FAQs of DIDW Centrifugal Fan 160 MM X 178 MM:

Q: How is the DIDW Centrifugal Fan mounted and connected?

A: The fan is base mounted, designed for secure installation on flat surfaces. Electrical connections are made through a terminal box, ensuring safe and straightforward wiring during setup.Q: What applications are best suited for this centrifugal fan?

A: This fan is ideal for HVAC systems, industrial air circulation, and general ventilation in factories, warehouses, and commercial facilities due to its high performance and robust construction.Q: When should the serviceable parts be inspected or maintained?

A: It is advisable to inspect and maintain the impeller, bearings, and motor periodically. Routine maintenance ensures optimal performance and extends the fans operational lifespan, which is approximately 40,000 hours.Q: Where can this fan operate effectively considering temperature and protection class?

A: The fan operates efficiently in environments with temperatures ranging from -10C to +60C and is rated IP44, making it suitable for moderate dust and moisture exposure typically found in industrial and commercial settings.Q: What is the process for replacing serviceable parts?

A: To replace parts such as the impeller, bearings, or motor, ensure the power is disconnected, access the relevant component through the fan housing, and follow standard mechanical practices. Refer to the user manual for specific guidance.Q: What are the primary benefits of using a forward curved, double inlet centrifugal fan?

A: This design provides high airflow at lower noise levels and is compact, making it ideal for applications demanding efficient ventilation without compromising on space or acoustic comfort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 230 MM X 203 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Output Power : 0.75 kW

Pressure Range : 50150 mm WG

Dimension (L*W*H) : 230 mm x 203 mm

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

DIDW Centrifugal Fan 250 MM X 203 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Output Power : 0.75 kW

Pressure Range : Up to 60 mmWG

Dimension (L*W*H) : 250MM x 203MM

Product Type : Others, DIDW Centrifugal Fan

DIDW Centrifugal Fan 280 MM X 250 MM

Price 4000 INR

Minimum Order Quantity : 5 Pieces

Output Power : 0.75 kW

Pressure Range : 40 80 mm WG

Dimension (L*W*H) : 280 mm x 250 mm x 250 mm

Product Type : Others, Double Inlet Double Width Centrifugal Fan

DIDW Centrifugal Fan 230 MM X 127 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Output Power : 0.37 kW

Pressure Range : 450650 Pa

Dimension (L*W*H) : 230 mm x 127 mm x 200 mm (approx.)

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS