SS Magnehelic Gauge

SS Magnehelic Gauge Specification

- Seal Material

- Nitrile Rubber (Buna-N)

- Display

- Analog

- Outer Size

- 110 mm (Approx.)

- Grade

- SS 304/316

- Sensor Type

- Differential Pressure

- Thread

- 1/8 NPT Female

- Bourdon Tube

- Stainless Steel

- Material

- Stainless Steel

- Dial Material

- Aluminum with White Baking Finish

- Pointer Material

- Aluminum, Black Painted

- Processing Type

- Precision Engineered

- Diameter

- 100 mm / 110 mm

- Glass Size

- 100 mm

- Mount Type

- Surface/Panel Mount

- Scale Range

- 0-50 Pa to 0-10000 Pa (Custom Ranges Available)

- Accuracy

- 2% of Full Scale

- Finishing

- Mirror Polish/Satin

- Measure Pressure Of

- Air & Non-Corrosive Gases

- Accessories

- Mounting Bracket, Screws

About SS Magnehelic Gauge

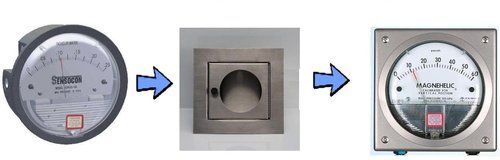

SS BOX Magnehelic Gauge

We are one of the topmost manufacturer, exporter and supplier of a superior quality range of& nbsp;SS BOX Magnehelic Gauge. These instruments are designed and made utilizing the finest grade raw material by following high definition engineering principles. Furthermore, these are widely appreciated for some of the salient features like accurate dimension, durability, superior performance and corrosion resistance. We provide these to our clients in both, standard and customized options according to the specific demands of customers.This SS-304, SS-202, stainless steel hinged box has a polished satin finish. This box has a hinged door with a face cutout to accept a Dwyer magnehelic pressure guage. Box comes complete with holes to accept pressure differential sensors. Box is fabricated with a flanged face for recess mounting.

Precision & Durability for Demanding Applications

Constructed from SS 304/316 stainless steel, this hermetically sealed Magnehelic Gauge ensures exceptional resistance to corrosion and environmental factors. The IP65 rating and shock-resistant design enhance longevity, making it suitable for sensitive areas like clean rooms and laboratories as well as robust industrial environments.

Flexible Installation & Operation

Offering both back and bottom 1/8 NPT female connections, this gauge adapts to diverse installation requirements. The included bracket and screws streamline mounting, whether on surfaces or panels. The external zero adjustment and clearly marked analog dial allow users to easily recalibrate and monitor differential pressure at a glance.

Comprehensive Calibration & Compliance

Each unit is factory calibrated and certified for accuracy (2% FS), ensuring trustworthy readings from the moment of installation. RoHS compliance guarantees minimal environmental impact, while a wide range of custom pressure scales fits various monitoring needs.

FAQs of SS Magnehelic Gauge:

Q: How do I install the SS Magnehelic Gauge for optimal performance?

A: The gauge can be surface or panel mounted using the included bracket and screws. Choose either the back or bottom 1/8 NPT female connection depending on your piping layout, and ensure it is securely fastened to maintain the IP65 protection and shock resistance.Q: What applications are best suited for this differential pressure gauge?

A: This Magnehelic Gauge is ideal for HVAC systems, clean rooms, filter and duct monitoring, and laboratory environments where precise measurement of air or non-corrosive gases is required.Q: What process should I follow to adjust the zero reading of the gauge?

A: Use the external screw located on the front of the unit to adjust the zero setting. Ensure the gauge is disconnected from pressure sources before making adjustments for safety and accuracy.Q: When should the gauge be recalibrated or certified?

A: Though it arrives factory calibrated and certified, recalibration cycles depend on your internal quality management standards or regulatory requirementstypically recommended annually in critical environments.Q: Where should the gauge be mounted for best results?

A: Mount the gauge on a vibration-free surface, away from direct exposure to harsh chemicals or extreme temperatures, within the specified range of -20C to +60C. This preserves accuracy and extends product life.Q: What are the primary benefits of selecting this stainless steel Magnehelic Gauge?

A: The main benefits include robust corrosion-resistant construction, easy installation, high accuracy (2% FS), shock resistance, and suitability for sensitive environments due to its hermetic seal and RoHS compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in TOP Dwyer Magnehelic Gauge Wholesale Suppliers India Category

Minihelic Differential Pressure Gauges

Mount Type : Other, Panel and Surface Mount

Grade : Industrial Grade

Accuracy : 5% of Full Scale (Standard)

Measure Pressure Of : Other, Air and NonCorrosive Gases

Seal Material : Silicone Rubber

Outer Size : Approx. 65 mm x 65 mm x 32 mm

Magnehelic Gauge Nozzles

Mount Type : Other, Panel Mount

Grade : Industrial

Accuracy : 2% of Full Scale

Measure Pressure Of : Other, Air and Noncorrosive Gases

Seal Material : Neoprene Rubber

Outer Size : Standard

GI Magnehelic Gauge Box

Mount Type : Flush Mount, Other

Grade : Industrial

Accuracy : 2% of full scale

Measure Pressure Of : Other, Air & Noncorrosive gases

Seal Material : Rubber gasket

Outer Size : 6 inches x 6 inches

Kimo Differential Pressure Transmitter- CP 113

Mount Type : Other, Wall Mount

Grade : Industrial

Accuracy : 1% of full scale

Measure Pressure Of : Other, Air and NonAggressive Gases

Seal Material : EPDM

Outer Size : 90 x 56.5 x 23 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS