Minihelic Differential Pressure Gauges

Minihelic Differential Pressure Gauges Specification

- Grade

- Industrial Grade

- Seal Material

- Silicone Rubber

- Thread

- 1/8 NPT

- Sensor Type

- Differential Pressure Sensor

- Display

- Analog

- Outer Size

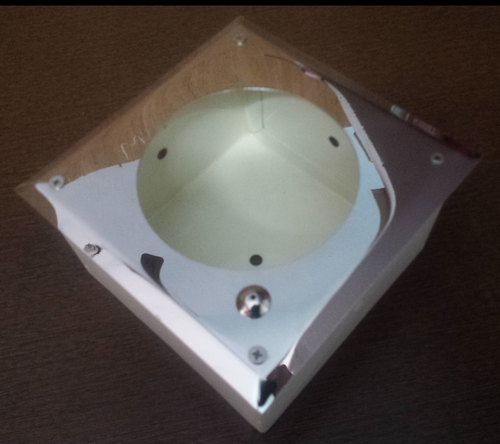

- Approx. 65 mm x 65 mm x 32 mm

- Bourdon Tube

- Not Applicable (Uses Diaphragm Mechanism)

- Material

- Polycarbonate Housing, ABS Front, Acrylic Lens

- Dial Material

- Aluminum (Printed)

- Pointer Material

- ABS

- Processing Type

- Injection Molded Housing

- Diameter

- 63 mm (Dial Face)

- Glass Size

- Approx. 44 mm (View Area)

- Mount Type

- Panel and Surface Mount

- Scale Range

- 0-50 Pa, 0-100 Pa, 0-200 Pa, 0-500 Pa, 0-1000 Pa, 0-2000 Pa (Model Dependent)

- Accuracy

- 5% of Full Scale (Standard)

- Finishing

- Powder Coated (Enclosure)

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Panel Mounting Bracket, 2 Connectors, Mounting Screws

About Minihelic Differential Pressure Gauges

Features are as follows:

- Combining high accuracy

- Longer life

- Compactness

- Dependability

- Most affordable prices

Robust Build and Versatility

Crafted with a robust polycarbonate and ABS structure, the Minihelic Differential Pressure Gauge offers reliability in demanding environments. Its medium shock resistance, IP40 protection, and powder-coated enclosure ensure durability. Designed to measure air and non-corrosive gases, it adapts to panel or surface mounting, making it ideal for varied industrial applications.

Precise Monitoring, Easy Integration

The analog dial provides clear pressure readings, supported by a factory-calibrated diaphragm mechanism for consistent accuracy. Model-dependent scale ranges and convenient 1/8 NPT rear connections make integration into panels straightforward. Supplied with mounting accessories, this gauge simplifies installation, letting users quickly set up and monitor differential pressure.

FAQs of Minihelic Differential Pressure Gauges:

Q: How is the Minihelic Differential Pressure Gauge typically installed?

A: The gauge is designed for flexible installation and can be either panel-mounted or surface-mounted. It comes with a panel mounting bracket, connectors, and screws, allowing straightforward integration into equipment cabinets or process setups.Q: What pressure ranges does the Minihelic Differential Pressure Gauge support?

A: Depending on the selected model, this gauge measures differential pressure in ranges from 050 Pa up to 02000 Pa, offering accurate monitoring for various air and non-corrosive gas applications.Q: Where can the Minihelic Differential Pressure Gauge be used?

A: Suitable for industrial environments, it can be installed in HVAC systems, cleanrooms, filter monitoring setups, and any application where monitoring low differential pressure of air or inert gases is essential.Q: What benefits does the clear acrylic lens and black pointer provide?

A: The clear acrylic lens offers excellent visibility and scratch resistance, while the black ABS pointer enhances readability, making pressure readings quick and precise even in less-than-ideal lighting.Q: What is the process for connecting the gauge to a system?

A: The gauge uses a 1/8 NPT thread connection at the back. To install, attach the provided connectors to the systems pressure ports and secure the gauge using the supplied mounting bracket and screws.Q: How is the accuracy of the gauge ensured?

A: Each gauge is factory calibrated and meets an accuracy standard of 5% of full scale, ensuring precise measurements and compliance with CE certification.Q: What gases can be measured with this differential pressure gauge?

A: The Minihelic is optimized for air and non-corrosive gases, using a silicone rubber seal and aluminum printed dial, which together prevent chemical reaction and extend the life of the instrument.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in TOP Dwyer Magnehelic Gauge Wholesale Suppliers India Category

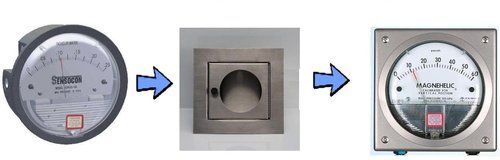

Magnehelic Gauge SS Plate Front Cover

Processing Type : Other, CNC Machined

Finishing : Other, Matte Brushed

Outer Size : 110 mm (Diameter)

Material : Other, Stainless Steel (Front Cover)

Accuracy : 2% of Full Scale

Grade : SS304

SS Magnehelic Gauge

Processing Type : Other, Precision Engineered

Finishing : Other, Mirror Polish/Satin

Outer Size : 110 mm (Approx.)

Material : Stainless Steel

Accuracy : 2% of Full Scale

Grade : SS 304/316

GI Magnehelic Gauge Box

Processing Type : Other, Pressure sensing

Finishing : Other, Polished stainless steel box

Outer Size : 6 inches x 6 inches

Material : Stainless Steel

Accuracy : 2% of full scale

Grade : Industrial

Kimo CP 300 Pressure Transmitter

Processing Type : Other, Microprocessor Based

Finishing : Other, ABS Housing, White

Outer Size : 87 x 62 mm

Material : Other, ABS Plastic

Accuracy : 0.5% of Full Scale

Grade : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS