Hydraulic Oil Filters

Hydraulic Oil Filters Specification

- Efficiency (%)

- Up to 99% (depending on micron rating)

- Filter Type

- Hydraulic Oil Filter

- Capacity

- Model dependent, designed for continuous operation

- Filtration Grade

- Temperature Range

- -20C to +120C

- Connecting Type

- Threaded and Flanged

- Media Type

- Wire mesh, Glass fiber, Paper

- Pressure

- Up to 30 bar

- Flow Rate

- 10-200 LPM (model dependent)

- Cleaning Method

- Replaceable or washable (depending on type)

- Condition

- New

- Material

- Stainless Steel, Mild Steel, Paper, Glass Fiber

- Mesh

- Stainless steel mesh (optional)

- Diameter

- Standard and custom sizes available

- Construction

- Cartridge and spin-on type

- Medium Filter

- Hydraulic Oil, Lubricating Oil

- Weight

- Depending on model (typically 0.5 to 3 kg)

- Shape

- Cylindrical

- Feature

- High dirt holding capacity, Durable construction, High filtration efficiency, Corrosion resistant

Hydraulic Oil Filters Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

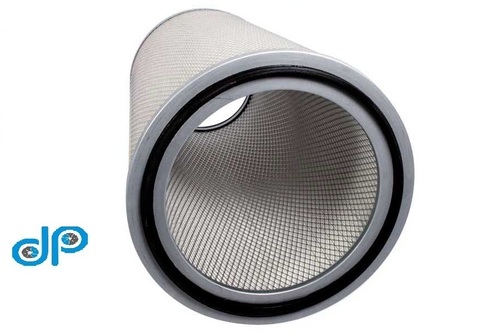

About Hydraulic Oil Filters

Hydraulic Oil FiltersWe are manufacturing and supplying Hydraulic Oil Filters. All our products conform their accordance with international standards. Moreover, these can be customized as per clients specifications and requirements. Before the final dispatch, these products are stringently checked by the quality analyzers on varied parameters to ensure their flawlessness.

Specifications:

Material: Cellulose Paper

Efficiency: F7Filtration

Grade: Medium

Filter Type: Cartridge Filter

Versatile Filtration for Demanding Applications

These hydraulic oil filters are designed for a multitude of operational environments, from industrial plants to construction and earthmoving sectors. Their corrosion-resistant build and customizable configurations ensure reliable filtration across a wide spectrum of hydraulic and lubricating oil systems. Choose from standard or custom diameters, various shapes, and multiple end connections to fit your specific machinery needs.

Advanced Filtration Efficiency and Durability

Leveraging high-grade filter media including stainless steel mesh, glass fiber, and paper, these filters ensure fine particle capture down to 10 microns. Their durable construction supports continuous performance and long life cyclesup to a year under normal operating conditions. This reduces maintenance frequency and lowers operational costs while maintaining system integrity.

FAQs of Hydraulic Oil Filters:

Q: How do I select the appropriate hydraulic oil filter for my equipment?

A: Selecting the right hydraulic oil filter depends on your machinerys flow rate, pressure requirements (up to 30 bar), micron rating (1025 micron or custom), connection type (BSP/NPT thread or flange), and the type of fluid used. Reviewing your systems manufacturers guidelines and operational environment (indoor/outdoor) helps determine the best fit.Q: What is the recommended replacement interval for these filters?

A: Replacement intervals vary based on operating conditions but generally follow your equipment maintenance schedule or a filter clog indicator. With a long life cycle, these filters may last up to one year under normal use, but it is prudent to inspect them regularly for optimal performance.Q: Where can hydraulic oil filters be installed?

A: These filters are suitable for a range of applications including hydraulic power packs, industrial machinery, earthmoving equipment, and construction machinery. Their robust design makes them ideal for both indoor and outdoor environments.Q: What are the benefits of using a high-efficiency hydraulic oil filter?

A: High-efficiency filters capture up to 99% of contaminants (depending on micron rating), significantly reducing wear on hydraulic components, extending equipment life, improving system reliability, and minimizing unscheduled downtime.Q: What is the cleaning or maintenance process for these filters?

A: Most models are replaceable, requiring simple removal and installation of a new filter. Certain types, depending on construction, are washable. Always follow the maintenance instructions provided for the filter type and your specific system.Q: Which materials are available for these hydraulic oil filters?

A: These filters are manufactured from stainless steel, mild steel, glass fiber, paper, and optional stainless steel mesh. The material choice should correspond to application demands, required corrosion resistance, and desired filtration efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

CYLINDRICAL FILTER CARTRIDGE

Feature : High Dirt Holding Capacity, Easy Installation and Replacement, Durable Construction

Medium Filter : Other, Liquid, Air, Gas

Cleaning Method : Other, Manual, Backwash

Weight : 500 g to 6 kg

Flow Rate : 10 m/h to 200 m/h

Shape : Cylindrical

Filter Baskets

Feature : Corrosion resistance, easy installation, reusable, high dirt holding capacity

Medium Filter : Other, Liquid, gas, air

Cleaning Method : Other, Manual, backflush

Weight : Varies by size (0.5 kg to 10 kg)

Flow Rate : Up to 1000 m/h

Shape : Cylindrical, basketshaped

8 Micron Hydraulic Filter

Feature : High dirt holding capacity, precise filtration

Medium Filter : Other, Hydraulic Oil

Cleaning Method : Other, Washable

Weight : 400 g

Flow Rate : 60 L/min

Shape : Cylinder

Automative Air Filter

Feature : High Durability

Medium Filter : Other, Activated Carbon

Cleaning Method : Other, Washable

Weight : 1.2 kg

Flow Rate : 600 cubic liters per minute

Shape : Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS