DIDW Centrifugal Fan 380 MM X 305 MM

DIDW Centrifugal Fan 380 MM X 305 MM Specification

- Flow Rate

- 1800-2500 m/h

- Power

- 0.75-2 HP

- Motor Power

- 1.5 kW

- Life Span

- 10 years (approx.)

- Max Pressure

- 50 mm WG

- Output Power

- 1.5 kW

- Pressure Range

- 35-50 mm WG

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 1800-2500 m/hr

- Pressure

- 35-50 mm WG

- Application

- Industrial Ventilation, Exhaust, HVAC

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- Below 75 dB

- Power Source

- Electric

- Voltage

- 220-415 V

- Weight

- Approx. 25 kg

- Dimension (L*W*H)

- 380 mm x 305 mm

- Color

- Blue

DIDW Centrifugal Fan 380 MM X 305 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Assam, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Tripura, South India, Central India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Gujarat, Delhi, Kerala, Odisha, Chhattisgarh, All India

About DIDW Centrifugal Fan 380 MM X 305 MM

DIDW Centrifugal Fan 380 MM X 305 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 56 | DP 15 12 | 380 X 305 X 300 | 15 X 12 | 25 MM,30 MM,& 1.25 | AL. / GI. |

Reliable Performance for Industrial Needs

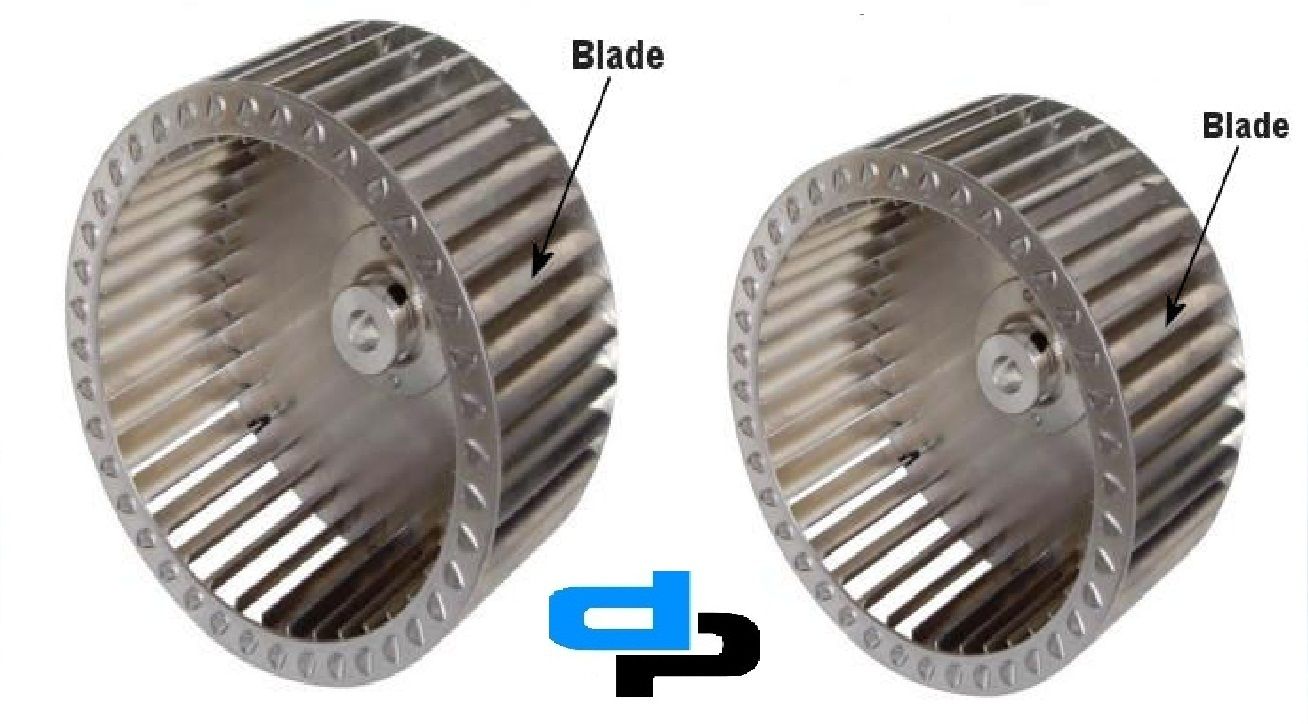

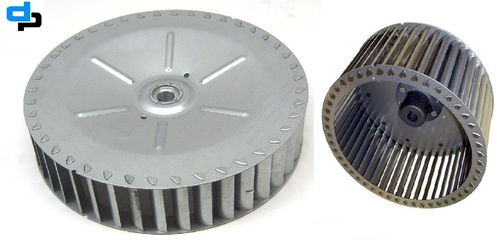

Designed for continuous duty cycles, the DIDW Centrifugal Fan delivers consistent airflow to support dust control, fume extraction, and air handling. Its backward curved impeller and base-mounted design maximize efficiency and reliability, essential for critical industrial environments.

Durable Construction and Safe Operation

Built from mild steel and featuring an IP55 protected, totally enclosed enclosure, the fan resists harsh operating conditions. Sealed ball bearings enhance its durability and longevity, promising a lifespan of approximately 10 years with minimal maintenance.

Flexible Application and Customization

Available with forward or backward curved blades per requirement, this fan adapts to varied airflow demands. Suitable for industrial ventilation and HVAC, it maintains noise levels below 75 dB, offering quieter operation. Various mounting and power options support diverse installations.

FAQs of DIDW Centrifugal Fan 380 MM X 305 MM:

Q: How does the DIDW Centrifugal Fan ensure efficient dust control and air handling?

A: The fan generates high airflow (1800-2500 m/h) with a backward curved impeller, optimizing air movement for dust control and effective ventilation in industrial settings.Q: What safety features does the fan offer during operation?

A: It features IP55 protection, a totally enclosed enclosure, and sealed ball bearings, minimizing exposure to dust, moisture, and external elements and ensuring safe, reliable performance.Q: Where is this fan primarily used?

A: The DIDW Centrifugal Fan is best suited for industrial environments requiring ventilation, exhaust, dust control, air handling, and fume extraction, commonly found in factories, warehouses, and large HVAC systems.Q: When is maintenance required for this fan and what does it involve?

A: Routine maintenance should be conducted periodically, focusing on belt tension, bearing lubrication, and cleaning the blades and housing to sustain optimal efficiency. Detailed schedules depend on operating conditions.Q: What are the benefits of the backward curved impeller design?

A: This impeller type delivers high efficiency and stable airflow with reduced risk of dust accumulation and lower noise emission, making it ideal for continuous operation in industrial applications.Q: How does the fan accommodate different installation needs?

A: It provides flexibility through options for forward or backward curved blades and base mounting. The belt-driven system and voltage range (220-415 V) support various industrial layouts and power sources.Q: What is the expected lifespan of the fan and how does its construction contribute?

A: Built with durable mild steel and high-quality sealed bearings, the fan has a typical lifespan of around 10 years, ensuring long-term reliability in rigorous environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 230 MM X 178 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Ventilation, HVAC systems, Air Handling Units, Industrial Exhaust

Voltage : 220240 V

Life Span : More than 20,000 hours

Color : Silver / Grey

DIDW Centrifugal Fan 455 MM X 380 MM

Price 16000 INR

Minimum Order Quantity : 2 Pieces

Application : Other, Industrial Ventilation, HVAC, Air Handling Units

Voltage : 415 V

Life Span : 10,000+ hrs

Color : Silver Grey

DIDW Centrifugal Fan 180 MM X 178 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Air Ventilation, HVAC, Industrial Exhaust

Voltage : 230 V AC

Life Span : >40,000 Hours

Color : Metallic Grey

DIDW Centrifugal Fan 280 MM X 280 MM

Price 4000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Industrial ventilation, Air handling units, HVAC systems, Exhaust and supply air systems

Voltage : 415 V

Life Span : 10 Years (Approximate)

Color : Silver / Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS