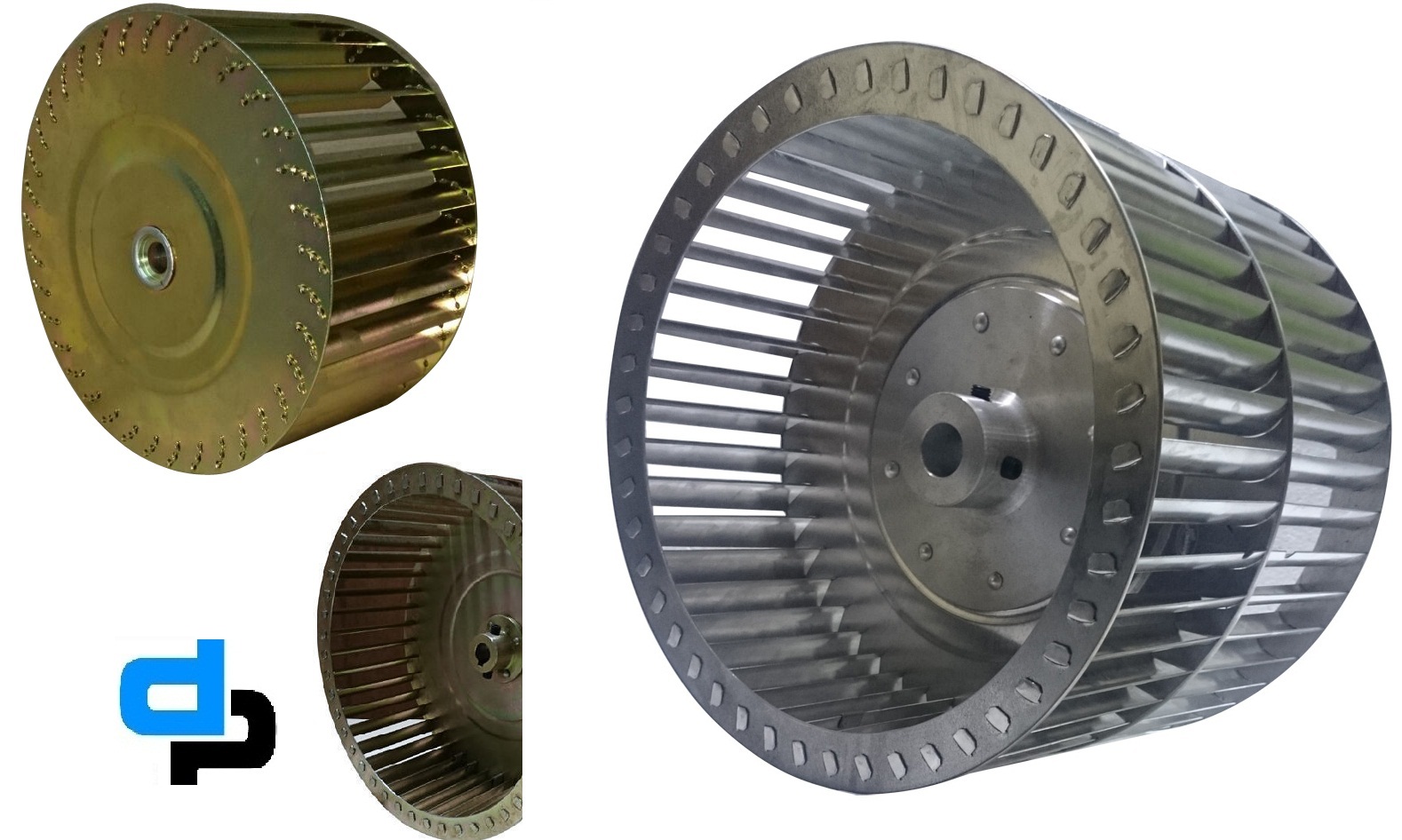

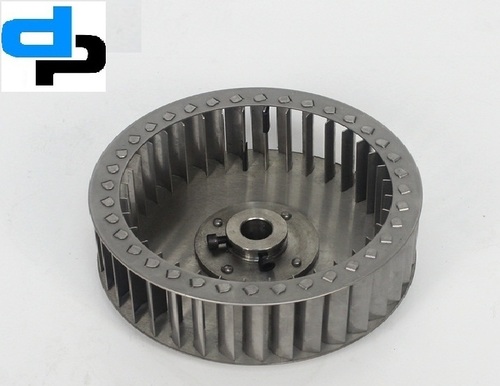

DIDW Centrifugal Fan 180 MM X 178 MM

DIDW Centrifugal Fan 180 MM X 178 MM Specification

- Max Pressure

- 400 Pa

- Flow Rate

- 450 m/h

- Pressure Range

- 250 Pa - 400 Pa

- Output Power

- 120 W

- Power

- 120 W

- Motor Power

- 0.18 HP

- Life Span

- >40,000 Hours

- Product Type

- Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- 450 m/h

- Pressure

- 350 Pa

- Application

- Air Ventilation, HVAC, Industrial Exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- 70 dB

- Power Source

- Electric

- Voltage

- 230 V AC

- Weight

- 6.5 Kg

- Dimension (L*W*H)

- 180 mm x 178 mm x 120 mm

- Color

- Metallic Grey

DIDW Centrifugal Fan 180 MM X 178 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Tripura, Himachal Pradesh, Manipur, Meghalaya, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Haryana, South India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Jammu and Kashmir, Jharkhand, Maharashtra, Mizoram, Punjab, Sikkim, Tamil Nadu, Telangana, West Bengal, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Gujarat, Madhya Pradesh, Rajasthan, Karnataka, North India, Kerala, Central India, Odisha, Chhattisgarh, All India

About DIDW Centrifugal Fan 180 MM X 178 MM

DIDW Centrifugal Fan 180 MM X 178 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 19 | DP 7 70 | 180 X 178 X 153 | 7 X 7 | 12.70 (1/2) & 15 MM | AL. / GI. |

Reliable Airflow for Demanding Spaces

The DIDW Centrifugal Fan is meticulously built to meet high standards in air ventilation and industrial exhaust. Its double inlet, 12-blade design ensures efficient airflow and pressure consistency, while ball bearing support extends longevity. Constructed from galvanized steel, the rigid frame resists corrosion and withstands tough environmental conditions.

Versatile Installation and Operation

This centrifugal fan offers flexible installation optionsfloor or wall mounted with standard foot mountingto fit diverse settings. Operating at 230V and a motor speed of 2800 RPM, it swiftly delivers up to 450 m/h airflow with minimal noise, suitable for HVAC systems, manufacturing units, and commercial applications.

FAQs of DIDW Centrifugal Fan 180 MM X 178 MM:

Q: How is the DIDW Centrifugal Fan installed for optimal performance?

A: The fan offers versatile installation modes and can be mounted on the floor or wall using its standard foot mounting design. Ensure it is securely attached to a rigid, level surface and aligned with your ventilation ducts for efficient air movement.Q: What are the benefits of the double inlet and 12-blade design in this centrifugal fan?

A: The double inlet and 12-blade configuration enhance airflow efficiency, enabling the fan to deliver a high flow rate and maintain stable pressure. This design is particularly effective in achieving superior ventilation and exhaust capabilities in industrial and commercial environments.Q: When should the DIDW Centrifugal Fan be maintained, and what does maintenance involve?

A: The fan is designed for low maintenance with periodic checks recommended every few months. Maintenance typically involves inspecting the ball bearings, cleaning the blades, and ensuring there is no obstruction in the airflow. Lubrication of moving parts may be necessary in extended service intervals.Q: Where can this centrifugal fan be used most effectively?

A: This fan excels in air ventilation for HVAC systems, industrial exhaust setups, and environments subjected to high humidity and temperature variations. Its corrosion-resistant galvanized steel construction makes it suitable for factories, commercial buildings, and warehouses across India.Q: What is the process for connecting this fan to a power source?

A: To connect the fan, wire it to a 230V AC power supply with proper safety measures in place. Confirm compatibility with your sites electrical system and use reliable connectors to ensure stable operation and prevent power fluctuations.Q: How does the fans construction support operation in high-humidity and corrosive environments?

A: The rigid galvanized steel frame resists corrosion, and the ball bearing design ensures smooth operation even in humidity levels up to 90% RH. These features collectively extend the life span of the fan above 40,000 hours, reducing the risk of breakdowns.Q: What are the primary advantages for users of this centrifugal fan?

A: Users benefit from reliable, low-noise operation, high airflow capacity, long service life, and minimal maintenance requirements. The versatile mounting, robust build, and energy-efficient performance make it a cost-effective choice for both new and retrofit ventilation projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 280 MM

Price 3500 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Application : Other, Ventilation, Air Handling Units, Industrial HVAC

Frequency (MHz) : 50 Hz

Product Type : Others, DIDW Centrifugal Fan

DIDW Centrifugal Fan 200 MM X 127 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Application : Other, Air Ventilation, HVAC, Exhaust

Frequency (MHz) : 50 Hz

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

DIDW Centrifugal Fan 180 MM X 152 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Application : Other, Ventilation, Air Handling Units, HVAC Systems

Frequency (MHz) : 50 Hz

Product Type : Others, DIDW Centrifugal Fan

DIDW Centrifugal Fan 180 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Application : Other, Ventilation, Air Handling Units, HVAC Systems, Industrial Air Circulation

Frequency (MHz) : 50 Hz

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS