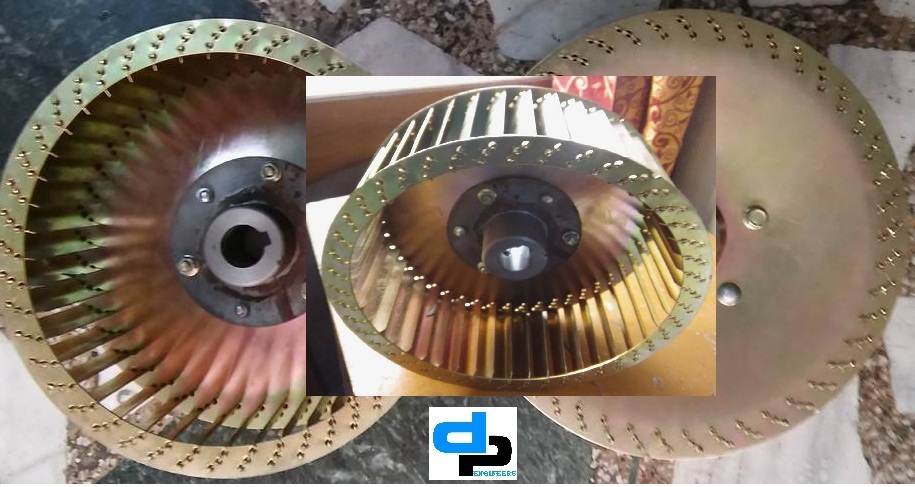

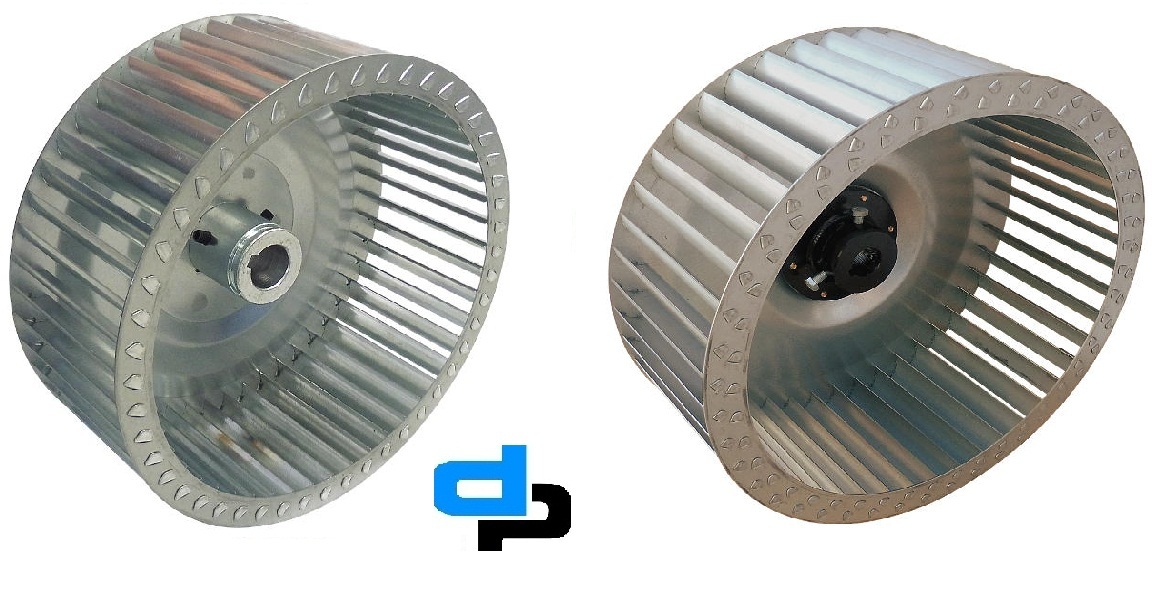

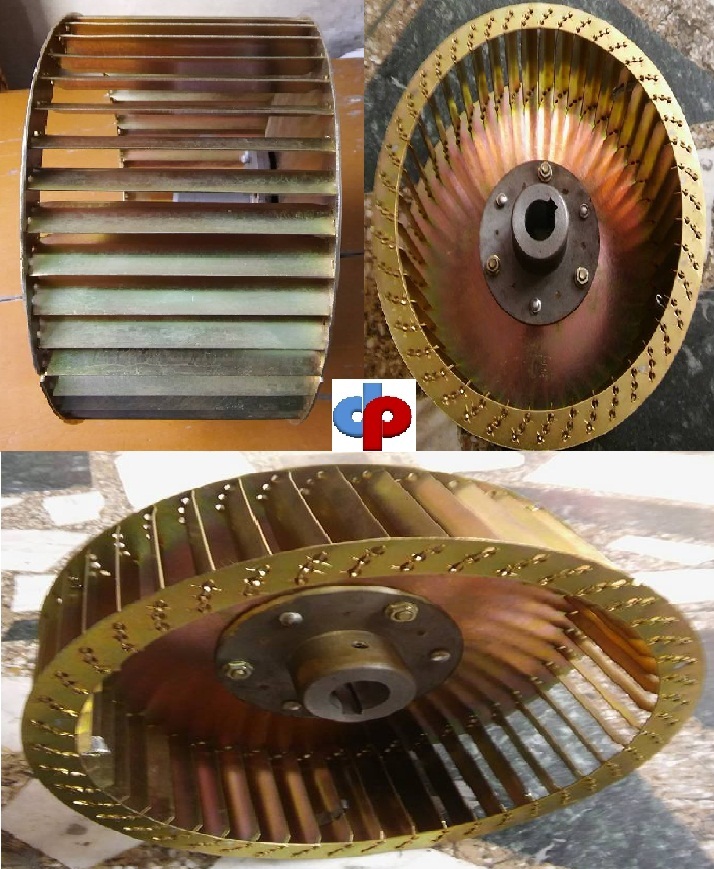

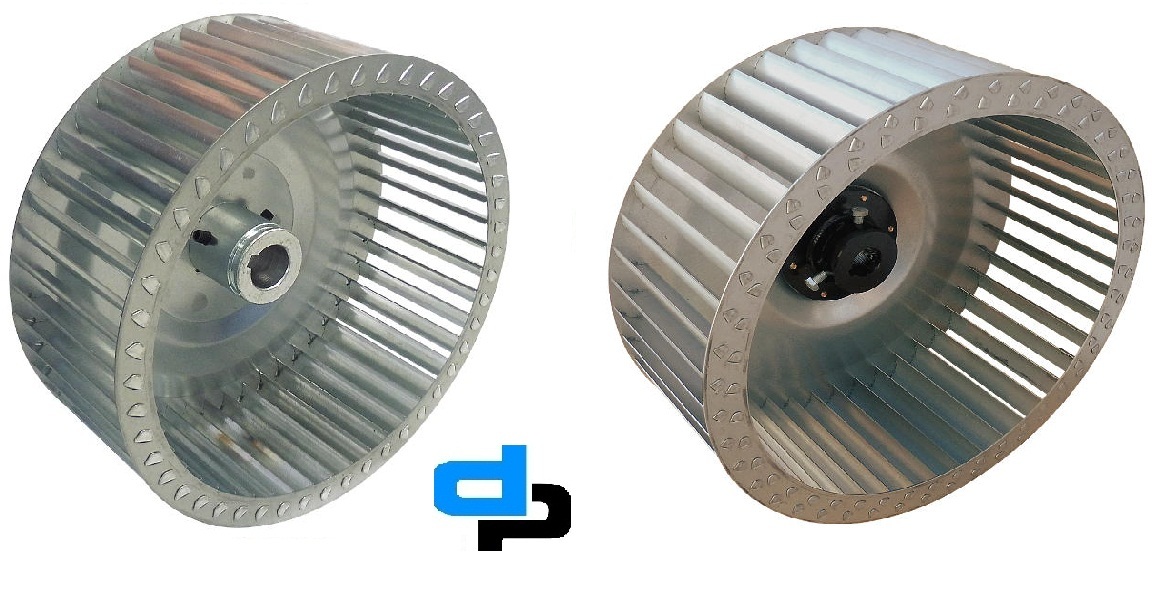

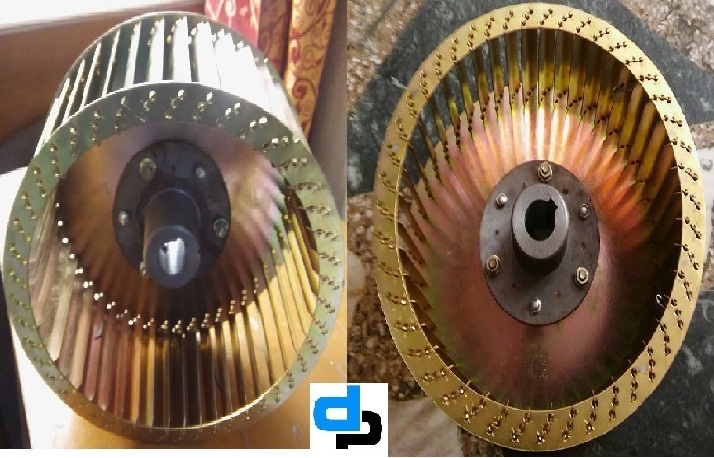

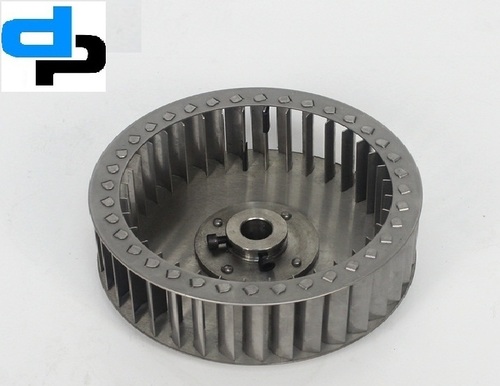

DIDW Centrifugal Fan 280 MM X 280 MM

DIDW Centrifugal Fan 280 MM X 280 MM Specification

- Output Power

- 1.1 KW

- Pressure Range

- 300 - 500 Pa

- Max Pressure

- 500 Pa

- Motor Power

- 1.5 HP

- Power

- 1.1 KW

- Life Span

- 10 Years (Approximate)

- Flow Rate

- 1200 CFM

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 1200 m3/hr

- Pressure

- 450 Pa

- Application

- Industrial ventilation, Air handling units, HVAC systems, Exhaust and supply air systems

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <78 dB

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- 14 Kg

- Dimension (L*W*H)

- 280 mm x 280 mm x 250 mm (Approx.)

- Color

- Silver / Grey

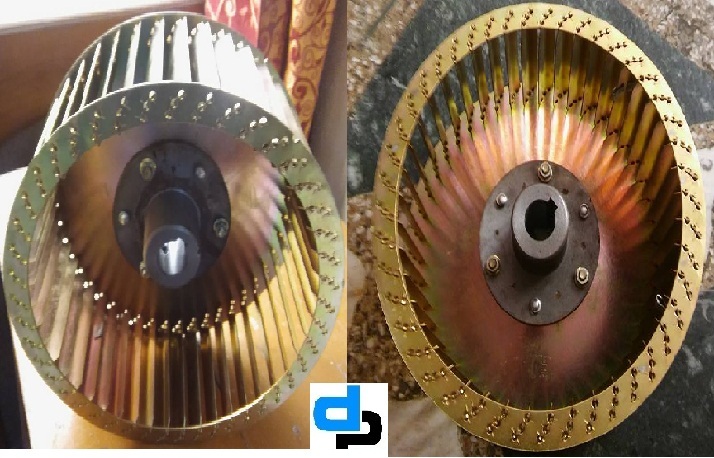

- Direction of Rotation

- Clockwise (viewed from drive end)

- Protection Class

- IP54

- Mounting Type

- Base Mounted

- Bearing Type

- Sealed Ball Bearing

- Insulation Class

- Class F

- Operating Temperature Range

- -10°C to +60°C

- Blade Material

- Steel with powder coated finish

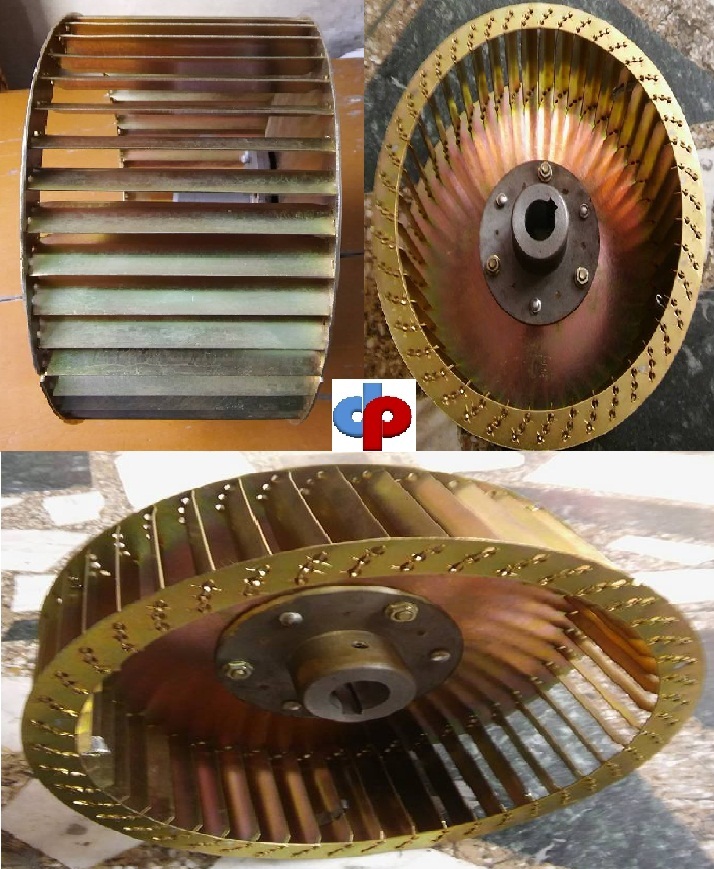

- Impeller Type

- Forward Curved

- Phase

- Three Phase

DIDW Centrifugal Fan 280 MM X 280 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Andaman and Nicobar Islands, South India, Central India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Delhi, Gujarat, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Pondicherry, Uttarakhand, Daman and Diu, All India

About DIDW Centrifugal Fan 280 MM X 280 MM

DIDW Centrifugal Fan 280 MM X 280 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 46 | DP 11 11 | 280 X 280X 229 | 11 X 11 | 12.70 (1/2) & 15 MM & 20 MM | AL. / GI. |

Advanced Industrial Ventilation Solutions

The DIDW Centrifugal Fan is meticulously crafted to meet rigorous industrial ventilation requirements. Its forward-curved impeller and IP54-rated enclosure ensure robust performance in demanding environments, such as air handling units and large-scale HVAC systems. High efficiency and reliable output make it a suitable choice for exhaust and supply air systems.

Durability and Superior Build Quality

The fan utilizes powder-coated steel blades and a mild steel body, offering impressive corrosion resistance and enhanced structural integrity. Sealed ball bearings further reinforce its durability, minimizing maintenance needs and extending operational lifespan, even under continuous use.

Optimized Performance with User Safety

Delivering up to 1200 m3/hr airflow at pressures up to 500 Pa, this fan maintains consistent air quality and circulation. Class F insulation and IP54 protection guarantee electrical safety, while a controlled noise level of below 78 dB promotes a more comfortable working environment.

FAQs of DIDW Centrifugal Fan 280 MM X 280 MM:

Q: How is the DIDW Centrifugal Fan installed in industrial settings?

A: The fan is base-mounted, making it straightforward to secure to floors or support structures. Its compact dimensions (280 mm x 280 mm x 250 mm) accommodate efficient integration within existing air handling units or ventilation systems.Q: What are the main benefits of using this centrifugal fan for HVAC systems?

A: Key advantages include reliable air circulation, low maintenance due to sealed bearings, high motor efficiency with steady output up to 1200 m3/hr, and protection against dust and moisture via its IP54 rating.Q: When should I consider replacing or servicing the fan?

A: Routine maintenance is minimal due to sealed ball bearings, but inspection after prolonged use or every few years is recommended. The fans expected lifespan is approximately ten years under normal operating conditions.Q: Where can this centrifugal fan be used most effectively?

A: It is well suited for industrial ventilation, air handling units, HVAC systems, and both exhaust and supply air requirements in manufacturing plants, warehouses, and other large facilities, especially throughout India.Q: What process does the fan employ to create airflow?

A: The forward-curved impeller, powered by a robust three-phase motor, efficiently draws air in and channels it at high speed, ensuring consistent pressure (300-500 Pa range) and a flow rate of up to 1200 CFM for optimal air movement.Q: How does the insulation class and protection class enhance user safety?

A: Class F insulation protects the motor from heat while the IP54 protection prevents dust and water ingress, significantly reducing the risk of electrical faults or short circuits during operation.Q: What are the usage recommendations to maximize fan life and performance?

A: Ensure the fan operates between its rated temperature range (-10C to +60C), provide adequate electrical supply (415V, 50Hz, three-phase), and keep the surrounding environment free from excessive dust or moisture for sustained optimal functionality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 280 MM

Price 3500 INR

Minimum Order Quantity : 5 Pieces

Output Power : 1.5 kW

Material : other , Mild Steel

Frequency (MHz) : 50 Hz

Weight : 15 kg

DIDW Centrifugal Fan 160 MM X 228 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Output Power : 370 W

Material : other , Mild Steel / Powder Coated

Frequency (MHz) : 50 Hz

Weight : Approx 8 kg

DIDW Centrifugal Fan 610 MM X 610 MM

Price 25000.00 INR

Minimum Order Quantity : 1 Piece

Output Power : 3.7 kW

Material : other , Mild Steel

Frequency (MHz) : 50 Hz

Weight : 68 kg

DIDW Centrifugal Fan 180 MM X 127 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Output Power : 0.37 kW

Material : other , Mild Steel

Frequency (MHz) : 50 Hz

Weight : Approx. 5 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS