DIDW Centrifugal Fan 272 MM X 272 MM

DIDW Centrifugal Fan 272 MM X 272 MM Specification

- Max Pressure

- 350 Pa

- Power

- 0.37 kW

- Motor Power

- 0.5 HP

- Life Span

- 10 Years

- Flow Rate

- Up to 900 m3/h

- Output Power

- 0.37 kW

- Pressure Range

- 100-350 Pa

- Product Type

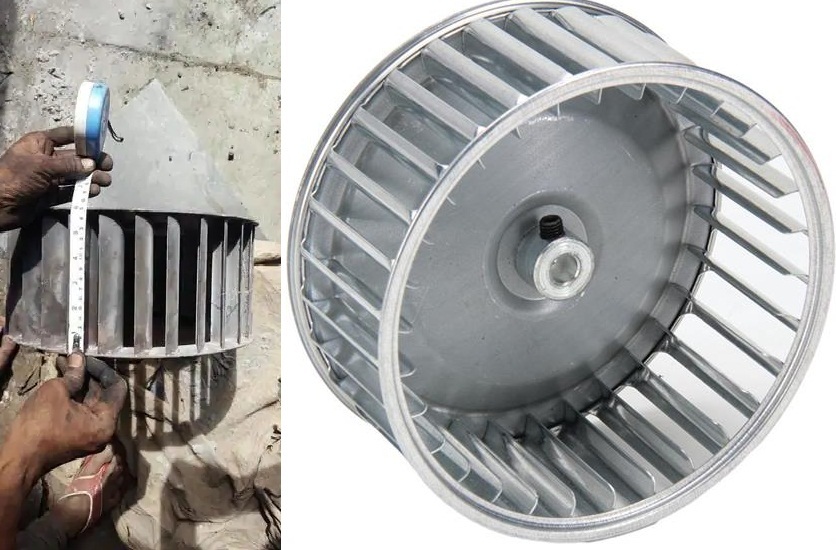

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- 500-900 m3/h

- Pressure

- 250 Pa

- Application

- HVAC, Industrial Ventilation, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 72 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- Approx. 8 kg

- Dimension (L*W*H)

- 272 mm x 272 mm x 150 mm

- Color

- Silver

- Efficiency

- High Efficiency Motor

- Static Pressure

- Up to 350 Pa

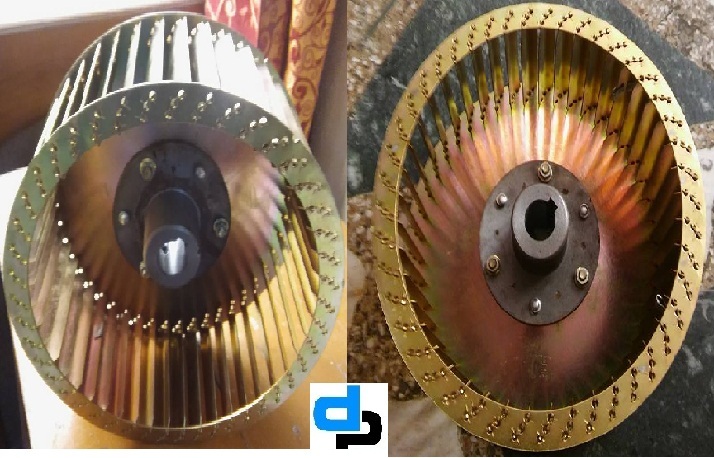

- Impeller Type

- Backward Curved

- Fan Construction

- Heavy Duty Riveted

- Bearing Type

- Sealed Ball Bearing

- Drive Type

- Direct Drive

- Mounting Type

- Base Mounted

- Enclosure Type

- IP55

- Temperature Range

- -10°C to 60°C

DIDW Centrifugal Fan 272 MM X 272 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Meghalaya, Andaman and Nicobar Islands, South India, Central India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, Jharkhand, All India

About DIDW Centrifugal Fan 272 MM X 272 MM

DIDW Centrifugal Fan 272 MM X 272 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 42 | DP 10 58 | 272 X 272X 229 | 10 5/8 X 10 5/8 | 12.70 (1/2) & 15 MM & 20 MM | AL. / GI. |

Engineered for Endurance

Constructed from galvanized steel and utilizing heavy-duty riveted fabrication, this fan promises excellent resilience against environmental stressors. The IP55 enclosure and sealed ball bearings assure reliable operation even under challenging conditions, enhancing the life span up to 10 years.

High Efficiency and Performance

With its backward curved impeller and high-efficiency motor, the fan delivers impressive airflow rates up to 900 m/h and maintains static pressure between 100 and 350 Pa. The direct drive system ensures minimal energy loss, making it a cost-efficient solution for ventilation and air handling.

Versatile Industrial Applications

Suitable for HVAC and various industrial settings, the DIDW centrifugal fan fits seamlessly into air handling units, offering effective air movement and ventilation. Its compact dimensions (272 x 272 x 150 mm) allow for flexibility in installation, matching different operational requirements.

FAQs of DIDW Centrifugal Fan 272 MM X 272 MM:

Q: How is the DIDW Centrifugal Fan installed in HVAC or ventilation systems?

A: The fan is base mounted and designed for straightforward installation in HVAC ducts, industrial ventilation setups, or air handling units. Its compact size and direct drive configuration make it easy to integrate with standard mounting practices.Q: What benefits does the backward curved impeller design provide?

A: The backward curved impeller enhances energy efficiency, reduces the risk of dust accumulation, and enables stable airflow at high static pressures, up to 350 Pa. This results in consistent performance and lower operating costs.Q: Where can this centrifugal fan be effectively used?

A: It is ideal for use in air handling units, HVAC systems, and various industrial environments needing reliable air movement, including factories, workshops, and commercial buildings throughout India.Q: What is the process for maintaining this centrifugal fan?

A: Routine maintenance involves periodic inspection of the sealed ball bearings and ensuring that the IP55 enclosure remains intact. The fans sturdy construction minimizes frequent servicing, supporting a service life of approximately 10 years.Q: When is it advisable to choose a heavy duty riveted construction fan?

A: Heavy duty riveted construction is recommended for applications requiring robust and durable fans capable of enduring high operational stresses and extended usage in tough environments.Q: What usage advantages are offered by direct drive technology in this fan?

A: Direct drive technology reduces energy loss and minimizes mechanical complexities, resulting in higher efficiency, lower operational noise, and less frequent maintenance compared to belt-driven models.Q: How does the high efficiency motor contribute to overall fan performance?

A: The high efficiency motor maximizes airflow delivery while conserving electrical energy, enabling the fan to maintain output power at 0.37 kW and flow rates up to 900 m/h, contributing significantly to energy savings and operational effectiveness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 530 MM X 530 MM

Price 21000.00 INR

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 530 mm x 530 mm x 650 mm

Power : 3 kW

Noise Level : <78 dB(A)

Max Pressure : 300 mm WC

DIDW Centrifugal Fan 530 MM X 380 MM

Price 18500 INR

Minimum Order Quantity : 2 Pieces

Dimension (L*W*H) : 530 mm x 380 mm

Power : 3 HP

Noise Level : Below 75 dB

Max Pressure : 400 mm WG

DIDW Centrifugal Fan 300 MM X 203 MM

Price 5500 INR

Minimum Order Quantity : 5 Pieces

Dimension (L*W*H) : 300 mm x 203 mm

Power : 1 HP

Noise Level : Low (<75 dB)

Max Pressure : 350 Pa

DIDW Centrifugal Fan 230 MM X 254 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Dimension (L*W*H) : 230 mm x 254 mm x 280 mm (approx.)

Power : 300 W

Noise Level : Less than 70 dB(A)

Max Pressure : 170 Pa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS