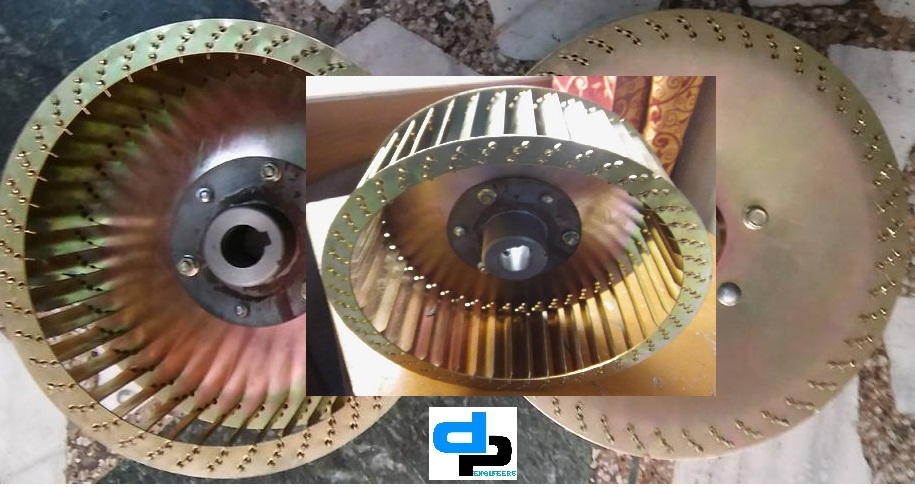

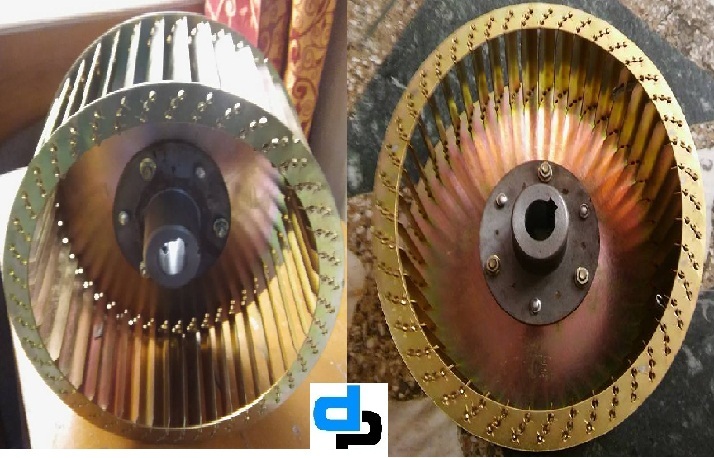

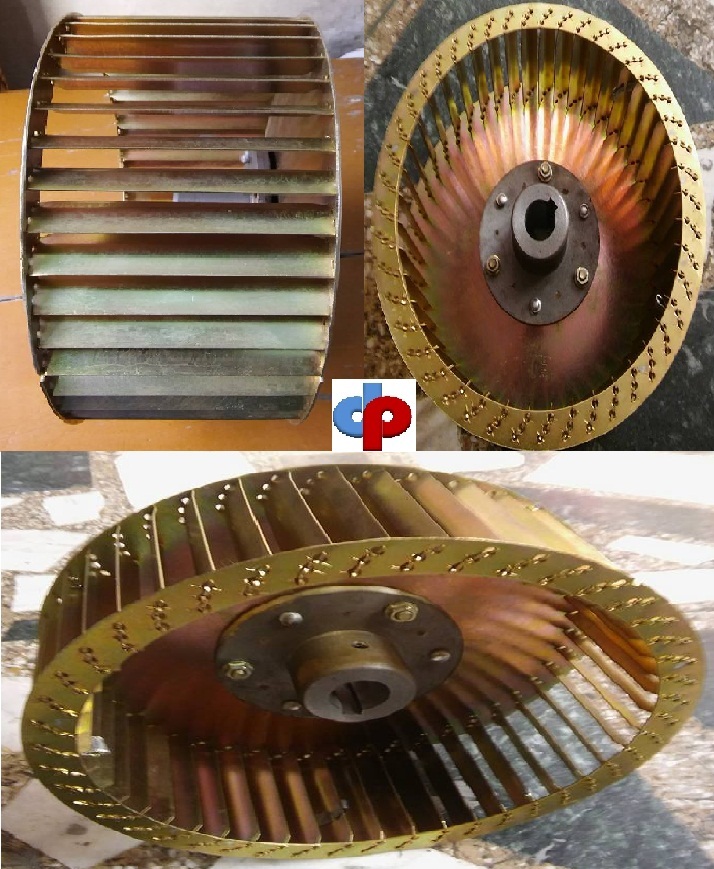

DIDW Centrifugal Fan 230 MM X 254 MM

MOQ : 5 Pieces

DIDW Centrifugal Fan 230 MM X 254 MM Specification

- Life Span

- 5-7 Years

- Power

- 300 W

- Max Pressure

- 170 Pa

- Output Power

- 0.37 kW

- Flow Rate

- 600 CFM

- Motor Power

- 0.37 HP

- Pressure Range

- 100-170 Pa

- Product Type

- DIDW (Double Inlet Double Width) Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- 600 CFM

- Pressure

- 150 Pa

- Application

- Industrial Ventilation, HVAC, Air Handling Units, Clean Rooms

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Less than 70 dB(A)

- Power Source

- Electric

- Voltage

- 230 V AC

- Weight

- 8.5 kg (approx.)

- Dimension (L*W*H)

- 230 mm x 254 mm x 280 mm (approx.)

- Color

- Silver/Grey

DIDW Centrifugal Fan 230 MM X 254 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Andaman and Nicobar Islands, South India, North India, East India, West India, Assam, Arunachal Pradesh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Bihar, Andhra Pradesh, Central India, Chhattisgarh, All India

About DIDW Centrifugal Fan 230 MM X 254 MM

DIDW Centrifugal Fan 230 MM X 254 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 35 | DP 9 10 | 230 X 254 X 190 | 9 X 10 | 12.70 (1/2'') & 15 MM | AL. / GI. |

Engineered for Industrial Efficiency

The DIDW Centrifugal Fan is tailored for heavy-duty air movement in industrial settings such as ventilation systems and HVAC infrastructure. Its forward-curved, double-inlet impeller configuration delivers both high efficiency and consistent airflow, making it a dependable choice for clean rooms and air handling applications.

Built to Last with Advanced Protection

Manufactured using galvanized steel and equipped with a sealed ball bearing system, this fan promises durability and corrosion resistance. The IP54 enclosure and Class F insulation provide extra protection, ensuring dependable performance even under rigorous environmental conditions found in industrial environments.

Ease of Maintenance and Operation

This centrifugal fan emphasizes serviceability, allowing straightforward access for easy maintenance and part replacement. With direct drive and a base-mounted design, users benefit from a simplified installation and reduced downtime, contributing to lower operational costs and an extended service life.

FAQs of DIDW Centrifugal Fan 230 MM X 254 MM:

Q: How does the forward-curved impeller benefit airflow efficiency in the DIDW Centrifugal Fan?

A: The forward-curved blades maximize the volume of air moved at lower noise and power consumption, ensuring efficient, continuous airflow (up to 600 CFM) ideal for HVAC and industrial ventilation applications.Q: What maintenance process is recommended for this centrifugal fan?

A: Routine inspections include checking the sealed ball bearings, cleaning the impeller and housing, and ensuring all replaceable parts are unobstructed. With its easy-maintenance design, most tasks can be performed quickly without extensive disassembly.Q: Where can the DIDW Centrifugal Fan be used most effectively?

A: It is best suited for industrial ventilation, HVAC systems, air handling units, and clean room environments in both manufacturing and processing facilities, owing to its robust airflow and reliable build.Q: What is the service life of the fan and when should major parts typically be replaced?

A: The expected lifespan is 57 years under standard operational conditions. Major replaceable parts, such as bearings or the impeller, should be checked annually and replaced as needed based on wear or manufacturer recommendations.Q: What are the main benefits of using a direct drive fan with a sealed ball bearing system?

A: Direct drive offers reduced mechanical complexity and less maintenance compared to belt-driven systems, while sealed ball bearings ensure smoother, quieter operation and longer service intervals.Q: How quiet is the DIDW Centrifugal Fan during operation?

A: With a noise level below 70 dB(A), the fan runs quietly for its size and capacity, making it suitable for noise-sensitive environments like clean rooms and controlled HVAC systems.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 151 MM X 165 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Color : Blue / Silver

Motor Power : 0.18 kW

Power : 0.18 kW

Max Pressure : 180 Pa

DIDW Centrifugal Fan 180 MM X 254 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Color : Silver / Grey

Motor Power : 1 HP

Power : 0.75 kW

Max Pressure : 140 mm WG

DIDW Centrifugal Fan 200 MM X 178 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Color : Metallic Grey

Motor Power : 1 HP

Power : 0.75 kW

Max Pressure : 350 mm WG

DIDW Centrifugal Fan 230 MM X 152 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Color : Silver Grey

Motor Power : 1 HP

Power : 0.75 kW

Max Pressure : 85 mm WG

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS