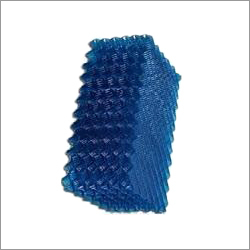

PVC Fills

PVC Fills Specification

- Application

- Cooling Towers, Heat Exchangers, HVAC Systems

- Material

- PVC (Polyvinyl Chloride)

- Condition

- New

- Type

- Cooling Tower Fills

- Dimension (L*W*H)

- 1200 mm x 600 mm x 150 mm (typical), customizable as required

- Cooling Type

- Cross Flow / Counter Flow

- Water Flowing Rate

- Varies as per system requirements

- Noise Control

- Yes, optimizes for quiet operation

About PVC Fills

- PVC Fills are made in tandem with defined norms of the arena using latest machines and quality assured materials.

- This, these are widely in demand.

Features:

- Light weight

- Longer service life

- Fire safe

- Comprehensive prices

- Decay proof

- Mass transfer & heat transfer coefficient

- Low pressure drop

Engineered for Performance and Versatility

These PVC fills are tailored to deliver superior heat transfer, thanks to advanced design features like high specific surface area and modular construction. Available in black, blue, or grey, they suit both new systems and upgrades. Compatibility with various tower designs ensures broad utility, while their robust construction supports effective cooling under challenging conditions.

Durability Meets Low Maintenance

Engineered from high-quality PVC, these fills are resistant to UV light and available with fire-retardant properties. Their service life extends beyond 10 years in standard operations, and their stackable shape makes cleaning and replacement straightforward. Users can expect dependable, long-term service with minimal maintenance requirements.

FAQs of PVC Fills:

Q: How do PVC fills enhance the cooling efficiency in cooling towers?

A: PVC fills significantly increase the contact surface area for water and air, which boosts heat exchange efficiency. Their honeycomb or wave-type structures promote optimized airflow and water distribution, resulting in improved cooling performance while maintaining minimal drift loss.Q: What installation process is recommended for these modular PVC fills?

A: Installation is streamlined due to the modular or stackable nature of the fills. They can be easily assembled or replaced, ensuring compatibility with both new and retrofitted cooling towers. Custom dimensions are available to suit specific tower designs or system needs.Q: When should fire-retardant and UV-resistant fill options be considered?

A: Fire-retardant grades are advisable for sites with stringent fire safety regulations. UV-resistant options are recommended for outdoor installations where prolonged sunlight exposure could otherwise degrade materials, thereby ensuring the longevity and safety of the fill packs.Q: Where can these PVC fills be effectively utilized?

A: These fills are suitable for a variety of applications, including cooling towers, heat exchangers, and HVAC systems. They are widely used in industrial, commercial, and utility settings anywhere efficient cooling and heat exchange are needed.Q: What is the typical lifespan and maintenance requirement for these fills?

A: Under normal operating conditions, these PVC fills last over 10 years. Maintenance is minimal; periodic inspection and cleaning are generally sufficient. The modular design enables quick removal and replacement, reducing system downtime.Q: How does the design contribute to noise reduction in cooling operations?

A: The optimized corrugated and chevron profiles facilitate smooth water flow and even airflow, which reduces turbulence and consequently, noise. This design ensures quieter overall operation of cooling towers and related systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cooling Tower Spare Parts Category

Splash Caps in Haridwar Uttarakhand

Minimum Order Quantity : 2000 Pieces

Application : Live stocks Greenhouses Gas Turbine Pre Cooler For Air Cooled Condenser Spray Painting Booth Industrial Applications Commercial Applications Humidification.

Type : pvc

Condition : New

Material : PVC

Dimension (L*W*H) : 63 Millimeter (mm)

63 mm PVC splash cap cooling Towers Nozzle in Karnataka

Minimum Order Quantity : 2000 Pieces

Application : Live stocks Greenhouses Gas Turbine Pre Cooler For Air Cooled Condenser Spray Painting Booth Industrial Applications Commercial Applications Humidification.

Type : pvc

Condition : New

Dimension (L*W*H) : 63 Millimeter (mm)

PVC Film Fill

Application : Cooling towers, industrial process cooling, HVAC systems

Type : Film Fill Media

Condition : Other, Brand New

Material : Other , Premium grade PVC (Polyvinyl Chloride) film

Dimension (L*W*H) : 1200 mm x 300 mm x 150 mm (custom sizes available)

Recycled Pvc Fill

Application : Cooling towers, water circulation systems, air conditioning plants

Type : Fill media

Condition : New

Material : Other , Recycled PVC

Dimension (L*W*H) : 600 mm x 300 mm x 150 mm (approx)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS