Industrial Pre Filters

Industrial Pre Filters Specification

- Cleaning Method

- Washable/Reusable

- Temperature Range

- -20C to 120C

- Pressure

- Maximum up to 10 Bar

- Flow Rate

- 1000 50000 m3/hr (customizable)

- Media Type

- SS Mesh, PP, Glass fiber

- Filtration Grade

- Industrial Pre-Filtration

- Capacity

- As per design (customizable)

- Filter Type

- Pre Filter

- Efficiency (%)

- Up to 98%

- Connecting Type

- Flange/Thread/Clamp

- Condition

- New

- Material

- Stainless Steel

- Mesh

- Available in 5 to 100 micron

- Diameter

- as per requirement (customizable)

- Construction

- Welded/Flanged/Clamped

- Medium Filter

- Air, Gas, Liquid

- Weight

- Varies by size/model

- Shape

- Cylindrical

- Feature

- High dirt holding capacity, durable construction, easy installation, large surface area

Industrial Pre Filters Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- 1 Week

- Main Export Market(s)

- Western Europe, Africa, Central America, Eastern Europe, Australia, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About Industrial Pre Filters

These Industrial Pre Filters are widely recognized by clients because of there fine Quality. These are supplied to all areas with best distribution network. D. P. Engineers was established in 1995 to cater the industry segment for their clean room requirement or HVAC Products Need.

These Pre Filters are made of very good Quality Raw Materials and are designed in such a way that they keep the dust or dirt out from the system. These are made to filter every single polluted particle so that fresh air passes through them.

Robust and Versatile Filtration Solution

Engineered from high-quality stainless steel and advanced filter media (SS Mesh, PP, Glass fiber), our Industrial Pre Filters are built to handle rigorous industrial applications. Suitable for both inside-out and outside-in flow directions, they offer exceptional efficiencyup to 98%and robust performance across a range of operating conditions. Their large surface area and adaptable configuration make installation, cleaning, and maintenance straightforward.

Customizable to Your Needs

With a wide selection of micron ratings (5100 micron), end connections, and diameters tailored to your operational requirements, our pre filters are available in various shapes and configurations. Whether you need welded, flanged, or clamped construction, every unit is designed to deliver consistent and reliable pre-filtration in your process line.

FAQs of Industrial Pre Filters:

Q: How are Industrial Pre Filters typically installed?

A: Industrial Pre Filters can be installed using flanged, threaded, or clamped end connections, making them compatible with a variety of piping systems. Their cylindrical construction and customizable diameters facilitate quick and easy integration into both new and existing setups.Q: What maintenance is required and how often should it be performed?

A: These pre filters are designed to be washable and reusable, ensuring longevity. Maintenance is typically required every 612 months, depending on contamination levels and process demands. Cleaning involves simple washing procedures, and the robust construction supports repeated use.Q: Where can these filters be used?

A: Our Industrial Pre Filters are suited for use in industrial settings such as HVAC systems, pharmaceutical manufacturing, chemical processing plants, and water treatment facilities. Their versatility also makes them effective for filtration of air, gas, and liquids in various industries.Q: What are the advantages of using these pre filters?

A: Key benefits include high dirt holding capacity, a large filtration surface area, easy installation, durable stainless steel construction, customizable size and micron rating, low initial pressure drop (<0.02 bar), and high filtration efficiency up to 98%.Q: How does the filtration process work with these filters?

A: The filter operates with either inside-out or outside-in flow direction, depending on your system configuration. It traps particulates using a selected mesh rating (5100 micron), ensuring contaminants are efficiently removed before downstream equipment or processes.Q: What is the rated working life of these filters?

A: The rated working life of our Industrial Pre Filters is up to 24 months, provided regular cleaning and maintenance are performed as recommended. Factors such as contamination load and operating conditions may impact actual service intervals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Filter Category

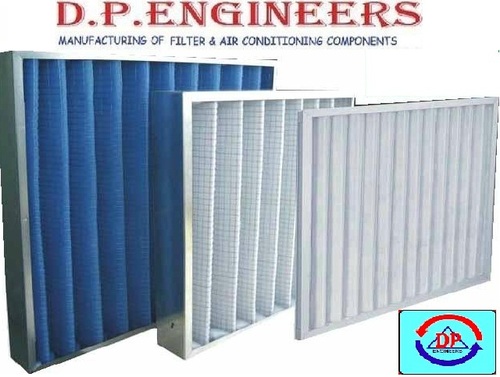

Pre Filters

Shape : Rectangular

Connecting Type : Other, Flange or Gasketed

Efficiency (%) : 8090%

Medium Filter : Other, Synthetic Media / Aluminum Mesh

Filter Type : Air Pre Filter

Diameter : Standard sizes, Custom sizes available

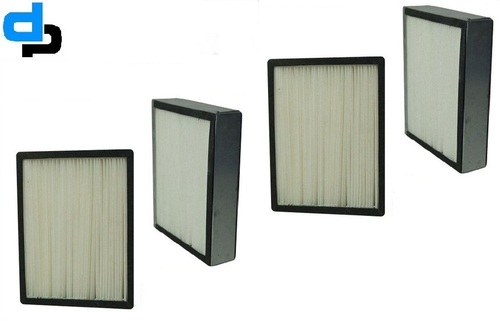

Microvee Type Fine Filter

Shape : Rectangular / Square

Connecting Type : Other, Flange / Custom mount

Efficiency (%) : 90 95% (approx) for 5 micron

Medium Filter : Other, Microsize nonwoven synthetic fiber

Filter Type : Microvee Type Fine Filter

Diameter : Custom as per requirement

AC HVAC Filter

Shape : Rectangular

Connecting Type : Other, Flange, Gasket

Efficiency (%) : Up to 99.97%

Medium Filter : Other, Synthetic Fiber

Filter Type : Panel Filter

Diameter : Customizable

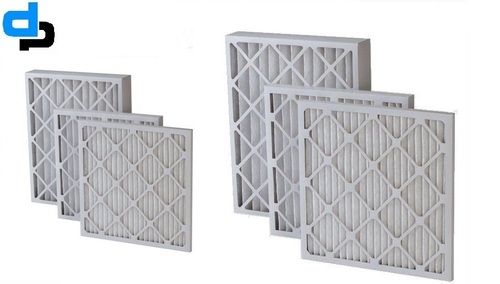

Furnace HVAC Filter

Shape : Rectangular

Connecting Type : Other, Insert Type (Fits Most Standard Housings)

Efficiency (%) : 85%

Medium Filter : Other, Synthetic Fiber

Filter Type : Panel Filter

Diameter : Standard Sizes Available (customizable on request)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS