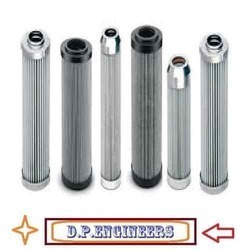

Filtration Element

Filtration Element Specification

- Capacity

- Customizable as per application

- Cleaning Method

- Backwash / Manual

- Efficiency (%)

- Up to 99%

- Flow Rate

- Up to 1500 L/h

- Temperature Range

- -20C to 180C

- Pressure

- Up to 10 Bar

- Connecting Type

- Flanged / Threaded

- Filtration Grade

- Industrial

- Media Type

- SS Mesh

- Filter Type

- Cartridge/Element Type

- Condition

- New

- Material

- Stainless Steel

- Mesh

- Fine mesh (typically 40 to 200 micron)

- Diameter

- Approx. 3 to 6 inches

- Construction

- Welded cylindrical body with end caps

- Medium Filter

- Liquid & Gas

- Weight

- Approx. 500g to 1.2kg

- Shape

- Cylindrical

- Feature

- High filtration efficiency, Easy installation, Durable and rust-resistant

About Filtration Element

Filtration Elements

Our offered ranges Filtration Elements that are widely appreciated for its best features like better performance, sturdiness, superiority and dependability.We are engaged in offering a comprehensive range of these products in a wide range in various varieties of dimensions. We offer them at affordable prices. We also supply these products at comprehensive prices and customize them as per the client choice.

Types Available

Filter simplex

Duplex

Portable filtration system

Spin on canisters

Available For Various Housings Machines and Equipments

Hydraulic Equipments

Turbines (Tiveni, BHEL, Apebellis, DLF, Metropolitan Vickers, Kessels, Thermodyne and other makes)

DG Dets ( Kirloskar, Cummins, Greaves (MWM) Skoda and other makes)

Compressors (K.G. Khosla, , C.P.T, Atlas Copco, Kay, Kirloskar Pneumatic, Holman Climax, Elgi and other makes.)

EDM/wire cut machines

Heavy earth moving equipment

Threads Used

BSP

NPT

BSW

UNF

Special Threads on demand

Media Used

Inorganic

Metal fiber and mesh

Micro glass

Glass fiber

Chrome nickel fiber

Nylon

Details

Complete filter : Simplex, Duplex, Portable Filtration System, Spin on Canisters

Flow Rating : 1 to 20,000 ltr/min.

Filtration Rating

1-5000 micron

Nominal and Absolute

Type : Low and High Pressure

Working Pressure(low and high pressure) : upto 6000 PSI Fluid Petroleum based Oils, Non-flammable fluids

Filtration Element

| Complete filter | Simplex, Duplex, Portable Filtration System, Spin on Canisters |

| Flow Rating | 1 to 20,000 ltr/min. |

| Filtration Rating | 1-5000 micron |

| Nominal and Absolute | |

| Type | Low and High Pressure |

| Working Pressure(low and high pressure) | upto 6000 PSI Fluid Petroleum based Oils, Non-flammable fluids |

High Durability and Corrosion Resistance

Constructed using premium stainless steel or aluminium, this filtration element is engineered for longevity. The high-grade materials ensure resistance to rust and corrosion, making the filter suitable for water treatment, oil filtration, and chemical processing industries. Even in harsh operating environments, the element maintains performance, helping reduce replacement frequency and long-term costs.

Versatile Applications and Easy Maintenance

Designed for versatility, this filter works with both liquid and gas media and can handle flow rates up to 1500 L/h. The element fits standard industrial housings, and installation is simple. Maintenance is streamlined through options for backwashing or manual cleaning, reducing downtime and extending service life while maintaining efficiency and reliability in critical processes.

FAQs of Filtration Element:

Q: How is the filtration element installed in industrial systems?

A: The filter element is designed for seamless installation, either by flanged or threaded connections, fitting standard industrial filter housings. This allows for quick integration without the need for extensive modifications.Q: What benefits does the stainless steel or aluminium construction offer for filtration?

A: Both materials provide excellent corrosion resistance and mechanical strength, making the filter ideal for challenging environments such as chemical processing or oil filtration. This robust construction extends the elements service life and maintains consistent filtration efficiency.Q: When should the filtration element be replaced?

A: Service life typically ranges from 1 to 2 years, depending on factors like the operating medium, flow rate, and particle load. Regular inspection and periodic cleaning are recommended, with replacement as soon as noticeable performance drops or pressure increases.Q: Where can this filtration element be applied?

A: The element is highly versatile and suitable for water treatment plants, petrochemical facilities, oil refineries, and any other place where reliable and robust fluid or gas filtration is needed. Its resistance to corrosive environments extends its usability across various industries.Q: What is the cleaning process for this filter element?

A: The filtration element supports both backwashing and manual cleaning methods. Regular cleaning helps maintain optimal performance and prolongs the service life of the filter, ensuring high filtration efficiency throughout its use.Q: How does surface filtration work in this element?

A: Surface filtration captures contaminants on the outer layer of the fine mesh, preventing particles from passing through while maintaining steady flow. This results in consistent high efficiency and makes cleaning simple, as collected debris remains on the surface.Q: What are the main advantages of using this filter in industrial applications?

A: Key benefits include high filtration efficiency (up to 99%), excellent durability, corrosion resistance, easy maintenance, and compatibility with customizable capacities. These features collectively ensure cleaner process media and lower operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

Hydraulic High Pressure Filter

Mesh : Fine Stainless Mesh

Filter Type : High Pressure Hydraulic Filter

Media Type : Other, Fiberglass, Cellulose, Wire Mesh

Weight : Approx. 25 kg

Construction : Other, Cartridge Type

Diameter : Approx. 60100 mm (varies by model)

RRR Oil Filter Elements

Mesh : Multilayered Filtration Mesh

Filter Type : Cartridge/Element

Media Type : Other, Synthetic & Cellulose Media

Weight : Depends on Model (Typically 300 g 1.2 kg)

Construction : Other, Pleated or Wrapped Type

Diameter : As per design (Standard/Custom options)

Hydraulic Oil Filters

Mesh : Stainless steel mesh (optional)

Filter Type : Hydraulic Oil Filter

Media Type : Other, Wire mesh, Glass fiber, Paper

Weight : Depending on model (typically 0.5 to 3 kg)

Construction : Other, Cartridge and spinon type

Diameter : Standard and custom sizes available

CONICAL FILTER CARTRIDGE

Mesh : Available in different micron ratings

Filter Type : Cartridge Filter

Media Type : Other, Stainless steel wire mesh or perforated sheet

Weight : As per size and construction

Construction : Other, Seamless welded construction

Diameter : Customizable as per requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS