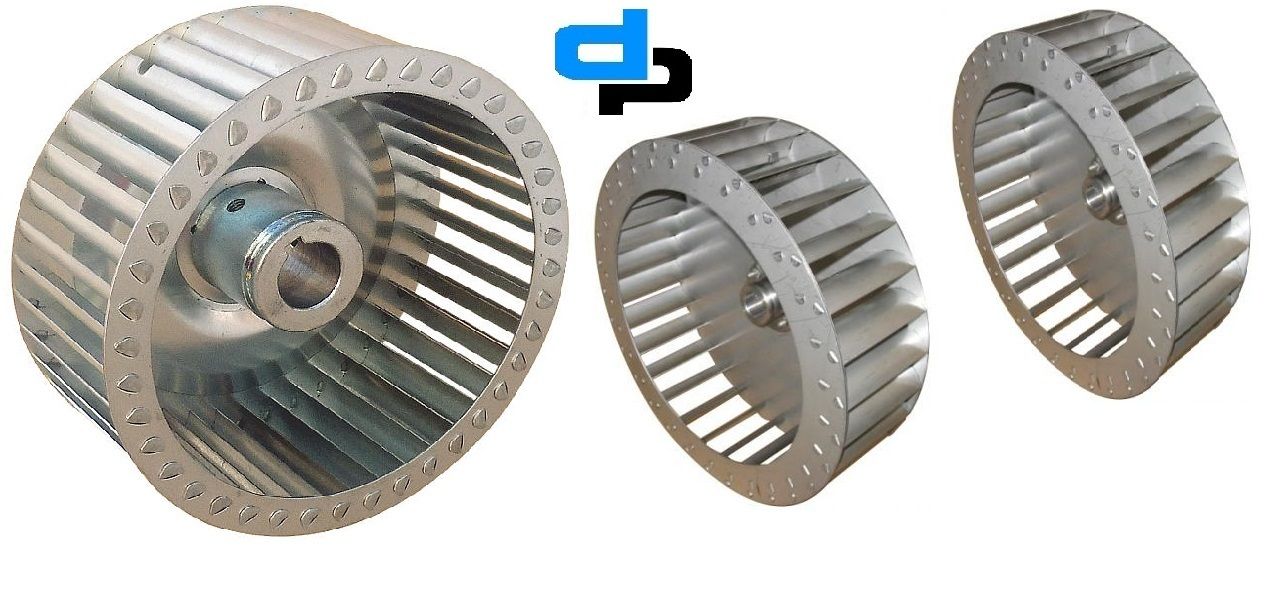

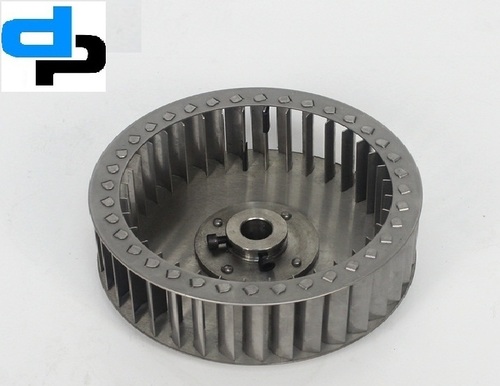

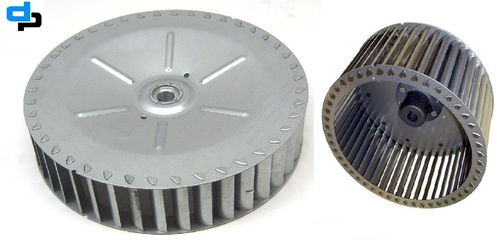

DIDW Centrifugal Fan 230 MM X 228 MM

DIDW Centrifugal Fan 230 MM X 228 MM Specification

- Max Pressure

- 200 mmAq

- Power

- 0.37 kW

- Life Span

- 7-10 Years

- Output Power

- 0.37 kW

- Flow Rate

- 850 m/h

- Motor Power

- 0.5 HP

- Pressure Range

- 120 - 200 mmAq

- Product Type

- Double Inlet Double Width Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- 850 CMH

- Pressure

- 200 mmAq

- Application

- Ventilation, Air Handling Units, HVAC Systems

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 70 dB

- Power Source

- Electric

- Voltage

- 230 V

- Weight

- 6.5 kg

- Dimension (L*W*H)

- 230 mm x 228 mm x 250 mm

- Color

- Grey

DIDW Centrifugal Fan 230 MM X 228 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Jammu and Kashmir, Sikkim, Tripura, Manipur, North India, East India, West India, Assam, Bihar, Chhattisgarh, Delhi, Gujarat, Goa, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Punjab, Rajasthan, Tamil Nadu, Telangana, West Bengal, Uttar Pradesh, Meghalaya, Arunachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, Haryana, South India, Andhra Pradesh, Central India, Odisha, All India

About DIDW Centrifugal Fan 230 MM X 228 MM

DIDW Centrifugal Fan 230 MM X 228 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

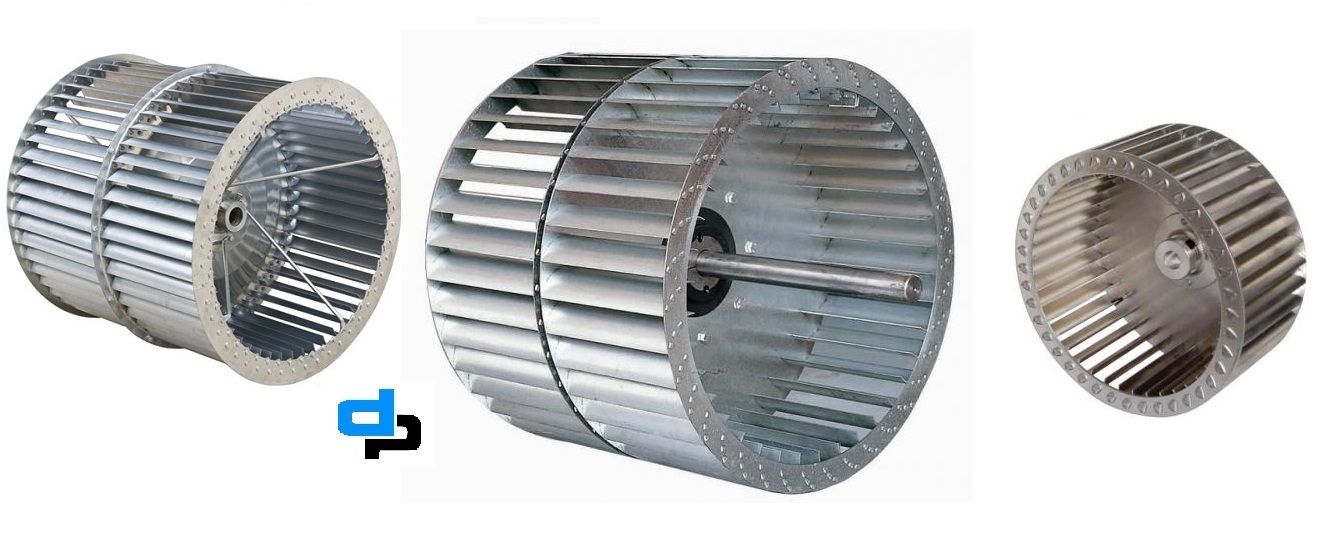

| 34 | DP 9 90 | 230 X 228 X 190 | 9 X 9 | 12.70 (1/2) & 15 MM | AL. / GI. |

Efficient Ventilation for Modern Spaces

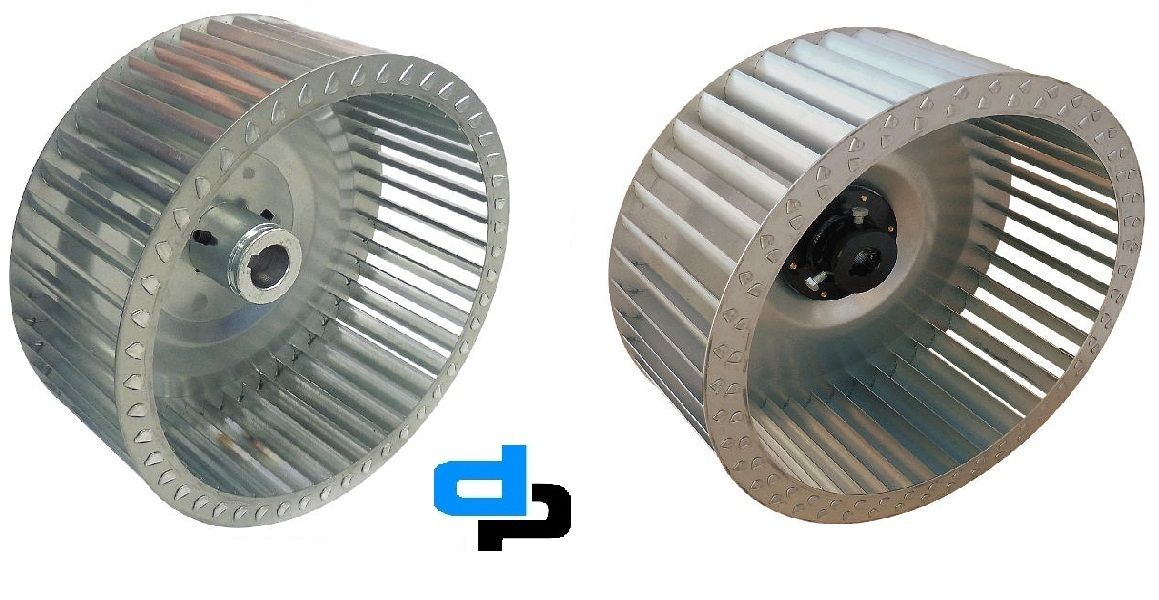

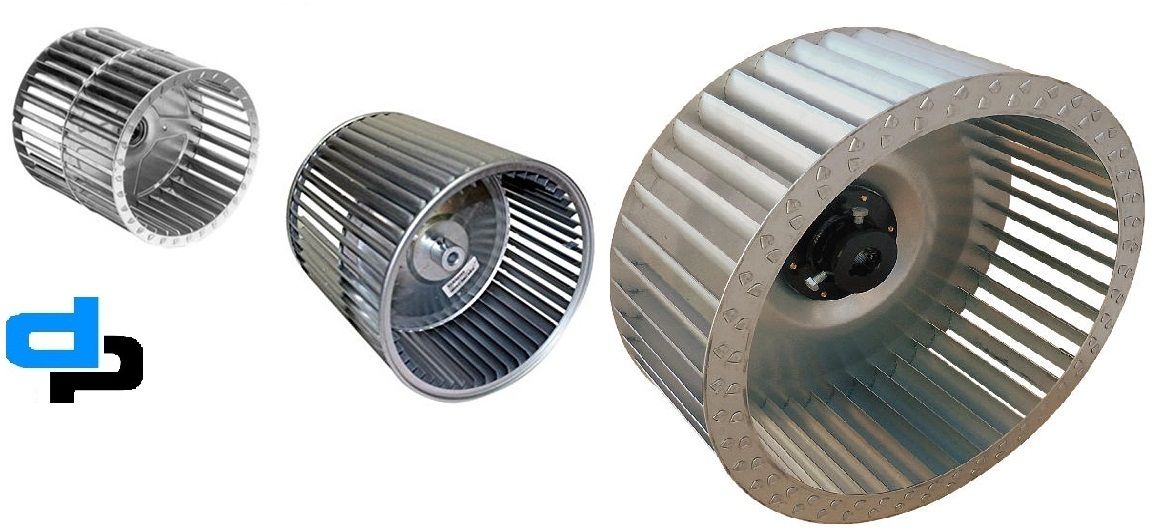

Designed to suit a range of air handling needs, this centrifugal fan provides powerful and consistent airflow for ventilation, HVAC systems, and air handling units. With its direct drive mechanism and forward curved impeller, it guarantees optimal air movement while maintaining energy efficiency in diverse installation settings.

Durable and Reliable Construction

Crafted with galvanized iron blades and a powder-coated mild steel frame, the fan resists corrosion and wear. Its sealed ball bearing system and IP54 enclosure ensure durability and protection against dust and moisture, making it a dependable choice for long-term use in challenging environments.

Flexible Installation Options

This fans base-mounted design and selectable air discharge direction (horizontal or vertical) allow for versatile placement, adapting to specific project requirements. Its compact dimensions and low weight facilitate easy integration into existing infrastructure.

FAQs of DIDW Centrifugal Fan 230 MM X 228 MM:

Q: How does the DIDW Centrifugal Fan optimize air movement in HVAC systems?

A: The fan uses a forward curved impeller and direct drive mechanism to provide a high flow rate of 850 m/h, ensuring efficient and uniform air distribution in ventilation and HVAC applications.Q: What installation processes are required for base-mounted models?

A: Installation involves securely fixing the fan base to a stable surface, connecting the electrical supply (230 V, 50 Hz), and adjusting the air discharge direction as needed. An electrician should handle wiring for safety and compliance.Q: Where can this centrifugal fan be used effectively?

A: It is suitable for commercial and industrial settings, such as within ventilation systems, air handling units, and HVAC applications, where reliable airflow and pressure control are required.Q: What benefits does the IP54 enclosure and sealed ball bearing provide?

A: The IP54 enclosure protects internal components from dust and water ingress, while the sealed ball bearing reduces maintenance, enhances operational reliability, and extends the fans service life.Q: What is the recommended operating temperature range for optimal performance?

A: The fan performs optimally within a temperature range of -20C to +60C, accommodating both cold and warm environments without compromising efficiency.Q: When should routine maintenance be carried out on this fan?

A: Routine maintenance should be performed every six to twelve months, focusing on cleaning and inspection to ensure continued efficient operation. The sealed ball bearings typically do not require lubrication.Q: How does using galvanized iron blades impact usage and longevity?

A: Galvanized iron blades offer superior resistance to corrosion, contributing to longer service life and consistent performanceideal for demanding air handling applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 280 MM

Price 3500 INR

Minimum Order Quantity : 5 Pieces

Motor Power : 2 HP

Max Pressure : 100 mm WG

Capacity : 1200 CFM

Motor Speed : 2800 RPM

DIDW Centrifugal Fan 250 MM X 254 MM

Price 3000 INR

Minimum Order Quantity : 5 Pieces

Motor Power : 1 HP

Max Pressure : 95 mm WC

Capacity : 1500 m/hr

Motor Speed : 1440 RPM

DIDW Centrifugal Fan 160 MM X 228 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Motor Power : 0.5 HP

Max Pressure : 260 mmWG

Capacity : 600 m/hr

Motor Speed : 2800 RPM

DIDW Centrifugal Fan 230 MM X 178 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Motor Power : 1 HP

Max Pressure : 350 Pa

Capacity : Max. 700 CMH (Cubic Meter per Hour)

Motor Speed : 2800 RPM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS