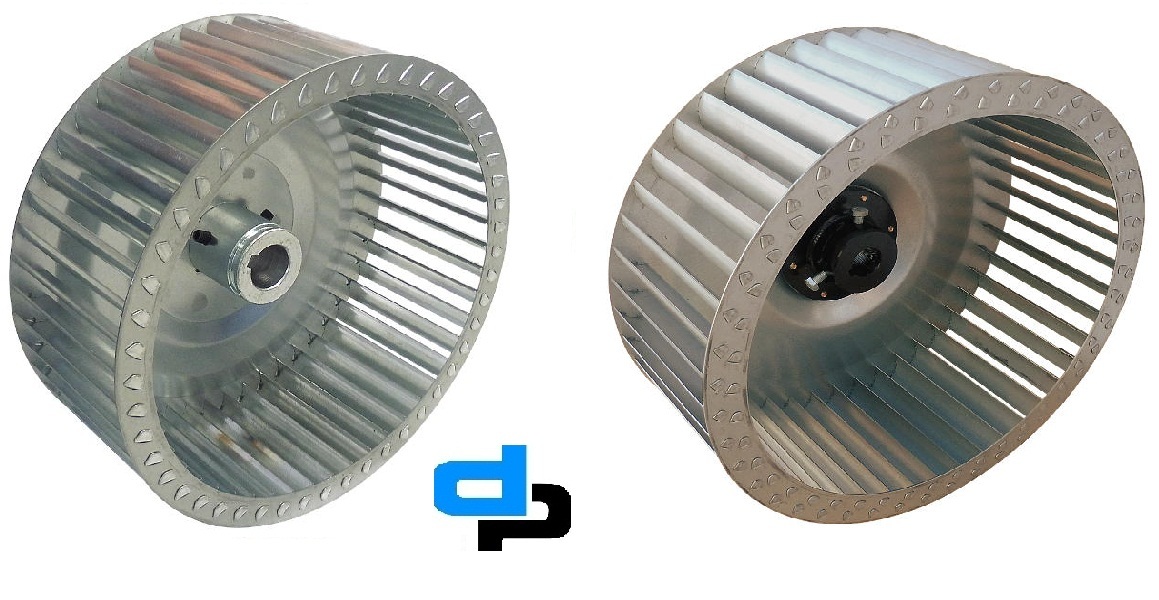

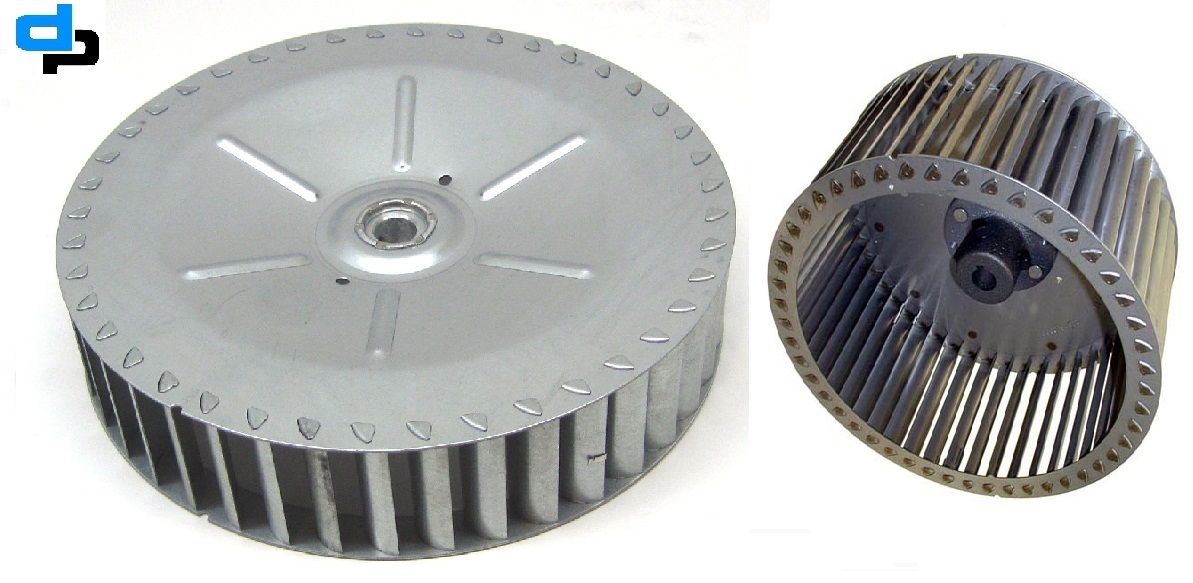

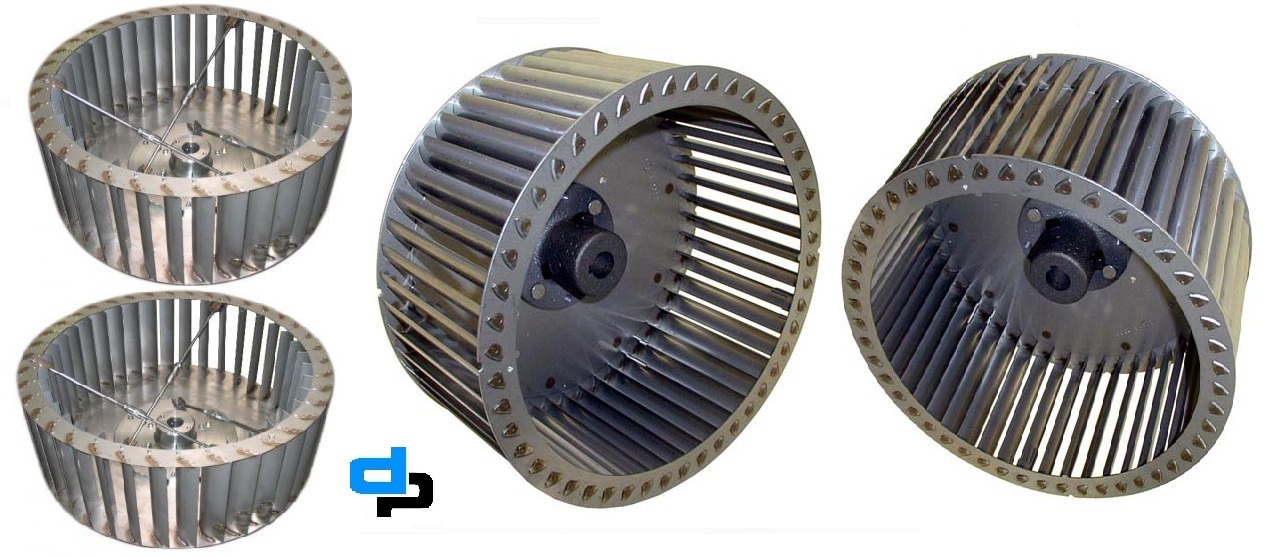

DIDW Centrifugal Fan 330 MM X 330 MM

DIDW Centrifugal Fan 330 MM X 330 MM Specification

- Life Span

- 10 Years (approximate with proper maintenance)

- Pressure Range

- 50 - 150 mm WG

- Power

- 1 HP

- Motor Power

- 0.75 kW

- Max Pressure

- 150 mm WG

- Flow Rate

- 1200 CFM

- Output Power

- 0.75 kW

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 1200 CFM

- Pressure

- Up to 150 mm WG

- Application

- Industrial Ventilation, HVAC, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 230 V / 415 V (single/three phase)

- Weight

- 18 kg

- Dimension (L*W*H)

- 330 mm x 330 mm

- Color

- Grey

DIDW Centrifugal Fan 330 MM X 330 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Tripura, Manipur, Andaman and Nicobar Islands, South India, North India, West India, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Daman and Diu, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Pondicherry, Uttarakhand, Dadra and Nagar Haveli, Uttar Pradesh, East India, Andhra Pradesh, Central India, All India

About DIDW Centrifugal Fan 330 MM X 330 MM

DIDW Centrifugal Fan 330 MM X 330 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 53 | DP 13 13 | 330 X 330 X 250 | 13 X 13 | 15 MM,20 MM,25 MM & 1 | AL. / GI. |

Efficient Air Movement for Industrial Needs

Designed for horizontal airflow, the DIDW Centrifugal Fan supports critical industrial environments like ventilation systems, air handling units, and HVAC applications. Its forward curved blade design enhances air delivery efficiency, while the powder-coated finish ensures resistance to corrosion, even under demanding conditions.

Engineered for Longevity and Quiet Operation

With heavy duty sealed ball bearings and a robust mild steel frame, the fan offers an estimated operational life span of up to 10 years with regular maintenance. The direct drive motor minimizes vibration and noise, maintaining sound levels below 80 dB and ensuring a comfortable workplace atmosphere.

Flexible Installation and Comprehensive Support

Base-mounted construction allows straightforward integration into new or existing setups. The product is backed by on-site technical support, empowering users with troubleshooting, maintenance, and operational assistance, making it a reliable solution for exporters, manufacturers, suppliers, and traders across India.

FAQs of DIDW Centrifugal Fan 330 MM X 330 MM:

Q: How is the DIDW Centrifugal Fan installed for optimal performance?

A: The fan features a base-mounted design, simplifying installation in horizontal airflow configurations. Ensure alignment with ductwork and secure mounting to minimize vibration. Installation is applicable in industrial ventilation systems, HVAC setups, and air handling units.Q: What materials and finishes enhance the durability of this fan?

A: Constructed from powder-coated mild steel, the fan is engineered to resist corrosion and withstand harsh operating environments. Its finish provides added protection and longevity, especially in industrial applications.Q: When should maintenance be conducted to extend the fans life span?

A: Regular maintenance, such as inspecting and lubricating sealed ball bearings, cleaning the blades, and checking electrical connections, should be performed according to manufacturer recommendations or at least annually to achieve the expected 10-year service life.Q: Where is this centrifugal fan typically used?

A: The DIDW Centrifugal Fan is ideal for industrial ventilation, air handling units, and HVAC systems. Its compact frame size allows flexibility for integration into diverse environments where efficient air movement and side discharge are required.Q: What is the process for troubleshooting operational issues with this fan?

A: If issues arise, such as unusual noise or reduced airflow, inspect for loose mounting, blocked inlet/discharge, and check motor power supply. On-site technical support is available to assist with diagnosis and repairs effectively.Q: How does the forward curved impeller design benefit airflow?

A: The forward curved blade impeller enhances air delivery by generating consistent flow rates up to 1200 CFM while maintaining low noise and moderate pressure. This design is effective for applications requiring reliable air circulation.Q: What certifications ensure the safety and quality of the fan?

A: The fan is both ISO 9001:2015 certified and CE marked, confirming adherence to international quality management and safety standards for industrial usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

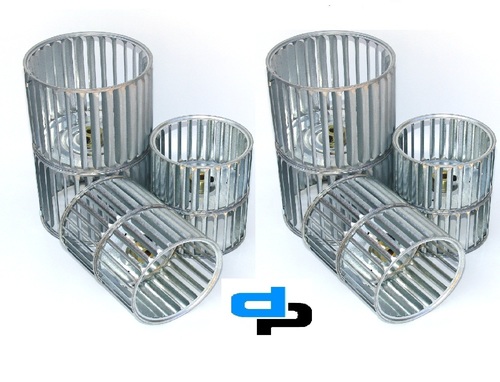

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 100 MM X 100 MM

Price 750 INR

Minimum Order Quantity : 5 Pieces

Color : Silver

Power Source : Other, Electric

Max Pressure : 90 mm WC

Flow Rate : 300 m/h

DIDW Centrifugal Fan 151 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Color : Silver

Power Source : Other, Electric

Max Pressure : 350 Pa

Flow Rate : 800 m3/h

DIDW Centrifugal Fan 250 MM X 228 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Color : Silver/Grey

Power Source : Other, Electric

Max Pressure : 350 Pa

Flow Rate : 1750 CMH

DIDW Centrifugal Fan 455 MM X 380 MM

Price 16000 INR

Minimum Order Quantity : 2 Pieces

Color : Silver Grey

Power Source : Other, Electric

Max Pressure : 100 mm WG

Flow Rate : 15002000 m/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS