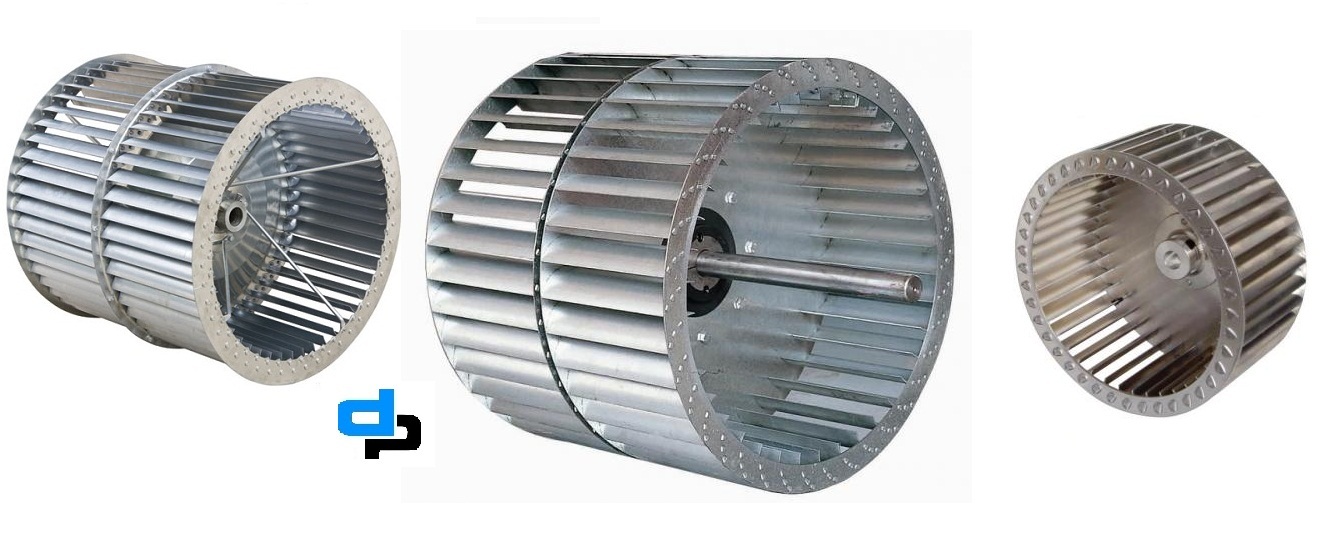

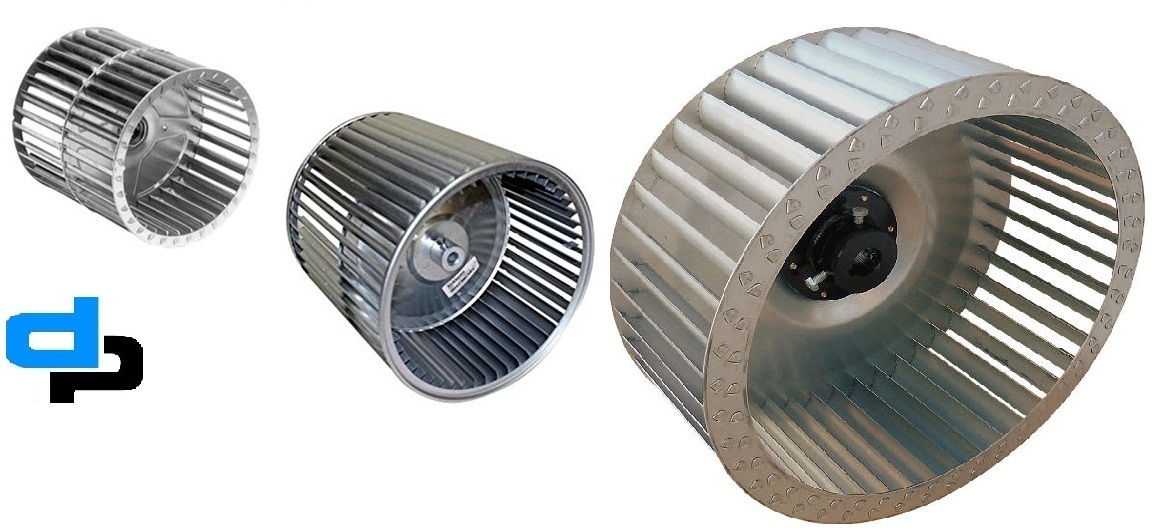

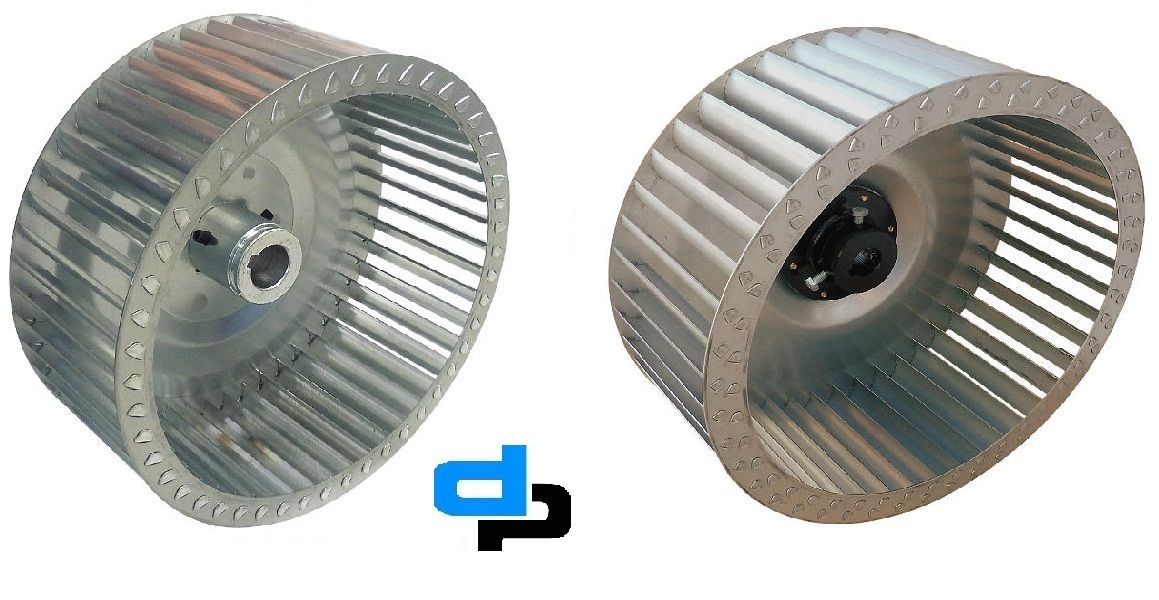

DIDW Centrifugal Fan 230 MM X 203 MM

DIDW Centrifugal Fan 230 MM X 203 MM Specification

- Motor Power

- 1 HP

- Life Span

- 15 Years

- Power

- 0.75 kW

- Pressure Range

- 50-150 mm WG

- Output Power

- 0.75 kW

- Max Pressure

- 150 mm WG

- Flow Rate

- 2500 m/h

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 2500 m/h

- Pressure

- Up to 150 mm WG

- Application

- Ventilation, Air Conditioning, Industrial exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <80 dB

- Power Source

- Electric

- Voltage

- 230 V

- Weight

- 11 Kg

- Dimension (L*W*H)

- 230 mm x 203 mm

- Color

- Blue

DIDW Centrifugal Fan 230 MM X 203 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Chandigarh, Jammu and Kashmir, South India, North India, East India, Assam, Bihar, Delhi, Gujarat, Goa, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Meghalaya, Arunachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Haryana, Andhra Pradesh, Central India, West India, Chhattisgarh, All India

About DIDW Centrifugal Fan 230 MM X 203 MM

DIDW Centrifugal Fan 230 MM X 203 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 33 | DP 9 80 | 230 X 203 X 190 | 9 X 8 | 12.70 (1/2) & 15 MM | AL. / GI. |

Reliable Performance and Durable Construction

Engineered with a powder-coated mild steel casing and ball bearing system, this centrifugal fan offers superior durability and stability. The forward-curved impeller and direct drive ensure high-volume airflow and efficient operation in demanding industrial settings, including ventilation and air conditioning.

Versatile Industrial Applications

With a substantial flow rate of 2500 m/h and a pressure range of 50-150 mm WG, this fan is ideal for various applications such as industrial exhaust, air conditioning, and ventilation systems. It maintains low noise levels (<80 dB) for a comfortable working environment.

Safety, Efficiency, and Long Life

Class F insulation, overload protection, and humidity tolerance up to 90% make this fan a safe and dependable choice. Its lifespan extends up to 15 years, ensuring long-term, efficient service while minimizing maintenance needs.

FAQs of DIDW Centrifugal Fan 230 MM X 203 MM:

Q: How is the DIDW Centrifugal Fan installed and what mounting type does it use?

A: The DIDW Centrifugal Fan is designed for base mounting, making it easy to install on stable surfaces in various industrial environments. Detailed installation guidelines are typically provided to ensure proper and secure setup.Q: What are the key benefits of using a forward-curved impeller in this fan model?

A: The forward-curved impeller enhances airflow efficiency at moderate pressure, making this fan particularly effective for ventilation and air conditioning where high air volume is required at lower noise levels.Q: When is it appropriate to use this fan in industrial settings?

A: This fan is well-suited for industrial exhaust, ventilation, and air conditioning applications, especially where reliable high-volume air movement is needed within a temperature range of -10C to 60C and up to 90% humidity.Q: Where is this centrifugal fan most commonly applied?

A: It is frequently used in factories, workshops, HVAC systems, and other industrial areas requiring robust ventilation or air extraction to maintain air quality and temperature control.Q: What process should be followed to maintain the DIDW Centrifugal Fan?

A: Routine maintenance includes checking the ball bearings, ensuring the fan casing remains free of dust and debris, and periodically inspecting the motor and overload protection system for optimal performance.Q: How does overload protection contribute to the safe usage of the fan?

A: Overload protection automatically interrupts power to the motor if an unsafe load is detected, thereby preventing damage to the fan and enhancing operator safety.Q: What advantages does the powder-coated mild steel casing offer?

A: The powder-coated finish adds an extra layer of protection against corrosion and wear, improving the fans resilience to harsh industrial environments and extending its operational life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 100 MM X 100 MM

Price 750 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Application : Other, Ventilation, HVAC, Dust Extraction

Frequency (MHz) : 50 Hz

Voltage : 230 V

DIDW Centrifugal Fan 200 MM X 203 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Application : Other, Ventilation, HVAC, Industrial Exhaust, Air Handling Units

Frequency (MHz) : 50 Hz

Voltage : 230 V / 415 V

DIDW Centrifugal Fan 280 MM X 305 MM

Price 4000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Application : Other, Ventilation, Air Handling Units, Industrial Exhaust

Frequency (MHz) : 50 Hz

Voltage : 220415 V

DIDW Centrifugal Fan 272 MM X 272 MM

Price 3500 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Application : Other, HVAC, Industrial Ventilation, Air Handling Units

Frequency (MHz) : 50 Hz

Voltage : 220240 V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS