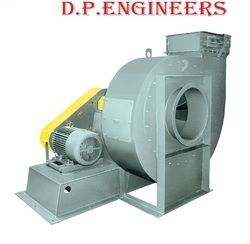

Ventilation Centrifugal Air Blower

Ventilation Centrifugal Air Blower Specification

- Output Power

- 2.2 KW

- Motor Power

- 3 HP

- Max Pressure

- 500 mmwc

- Pressure Range

- Up to 500 mmwc

- Life Span

- 10 Years

- Flow Rate

- 2500 m/hr

- Power

- 3 HP

- Product Type

- Centrifugal Air Blower

- Material

- Mild Steel

- Capacity

- 2500 m/hr

- Pressure

- 400 mmwc

- Application

- Ventilation, HVAC, Industrial Exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 220-415 V

- Weight

- 55 kg

- Dimension (L*W*H)

- 800 x 600 x 600 mm

- Color

- Blue

About Ventilation Centrifugal Air Blower

Ventilation Centrifugal Air Blower

We offer high quality Ventilation Centrifugal Air Blower for various applications such as fume extraction, dust collection, drying, ventilation purpose, material conveying, cooling etc. We have carved a remarkable position as the successful centrifugal blowers manufacturer across nation. High efficiency fans that are used in our centrifugal blower promise low power consumption. As per the demand of the patron, different ranges of pressure and volume ratio are available.

Features:

- Low power consumption

- High efficiency fans

- Accurate dimensions

- Exceptional quality

Ventilation In lines Air Blowers are very efficient and made for different types of Impellers or Rotors like Backward/forward Curved inclined bladed, Airfoil designs, Open Type, Multi blade Type, F type, Backward curved Impellers/Rotors, Forward curved Impellers/Rotors, etc.

Required Specifications for Ventilation Centrifugal Air Blowers:

- Air Volume

- Air Pressure

- Motor H.P.

- Blower R.P.M.

- Operating Temp

- Drive Type

- Construction of Material (M.O.C.)

- Ceramic and Refractories Industries,

- Chemical Factories,

- Cement Plants,

- Crucible Furnaces,

- Furnaces like Oil,

- Gas,

- Cupola Furnaces,

- Flour Mills,

- Rolling Mills,

- Boilers,

- Textile Mills,

- Cattle Feed Plants,

- Pharmaceutical Industries,

- Fertilizer Industries,

- Plastic Machinery Plants,

- Hot Mix Plants,

- Iron and Steel Plants,

- Paper Industries,

- Process Industries,

- and many more.

As Supply and Exhaust fans in Ventilation systems, In air handling units for air conditioning systems, In cold storage plants, For Fumes / Heat /Humidity / Smoke / Any other air Gases extraction and circulation in industrial plants/shed/covered-uncovered area, Industrial Blowers/Fans are widely used in Ventilation, Pollution Control, Fume Extraction, Dust collection, Induced Draft(ID Fans) and Forced Draft(F.D.Fans) for Boilers and Furnaces, Dust, suitable for various applications for Cooling, Humidification, Ventilation, Gas exhaust fans, Exhausters, fresh air supply, HVAC duties, Combustion for Burners, Recirculation of Fresh and United Air, etc.

Enviro Tech Industrial Products also Manufacturer, Supplier, Export, of Different Blowers, like Single Inlet Single Width Centrifugal Backward/Forward Curve Blowers (SISW Blowers), Airfoil Blowers, DIDW Blowers, Centrifugal Blowers, Air Blowers, Exhaust Blowers, Combustion Blowers, High Pressure Blowers, Low Pressure Blowers, Forced Draft Blowers(F.D.Fans), Induced draft Blowers(I.D.Fans), and all types of Industrial Fans.

Ventilation Centrifugal Air Blowers/Fans Features:

High efficiency, Low sound level, Compact Design, Large sizes can be dismantled, More Air with less HP, Easy in operation, Smooth in Running, Several versions available, etc.

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Versatile Mounting & High Durability

Designed for both floor and wall installations, this centrifugal air blower features a sturdy powder-coated mild steel construction that ensures reliability over extended use. The enclosure options (IP55/IP65) provide protection against dust and water, making it suitable for challenging industrial environments.

Efficient Performance for Varied Applications

With forward or backward curved impeller choices, direct or belt drive systems, and an operating temperature range up to 60C, this blower is adaptable for ventilation, HVAC, and exhaust applications. Its motor delivers up to 3 HP, ensuring efficient airflow and pressure across industrial setups.

Low Maintenance & Long Life Span

Equipped with ball bearings and designed to minimize maintenance, the blower promises a service life of up to 10 years. Its low noise level (below 80 dB) and high-quality components lessen downtime and operating costs, making it an excellent investment for long-term industrial use.

FAQs of Ventilation Centrifugal Air Blower:

Q: How do I select the appropriate impeller type for my application?

A: Choose between forward and backward curved impeller types based on your specific needs: backward curved impellers are ideal for higher efficiency at lower noise, while forward curved impellers are suitable for applications requiring higher airflow at lower pressures.Q: What are the benefits of having multiple mounting options for this blower?

A: With the flexibility to mount on either the floor or wall, this blower can be installed in a variety of locations, making it adaptable to limited spaces and different industrial layouts. This ensures optimal airflow distribution and ease of integration with existing systems.Q: When should I opt for a single phase or three phase blower model?

A: Select a single phase model for smaller, residential, or light commercial setups with standard power supplies. Opt for a three phase blower when installing in industrial environments where higher efficiency, stable operation, and greater power are required.Q: Where is this blower commonly used in industrial settings?

A: This centrifugal air blower is extensively used for ventilation, process air handling in HVAC systems, and industrial exhaust in factories, warehouses, and commercial buildings due to its powerful airflow and pressure characteristics.Q: What is the typical maintenance process, and how often should it be performed?

A: The blower is designed for low maintenance, primarily requiring periodic inspection of bearings, motor, and cleaning of the impeller to ensure optimal performance. Standard checks every 6-12 months are usually sufficient under normal operating conditions.Q: How does the powder coated finish and enclosure rating contribute to the blowers durability?

A: The powder coated finish protects the blower from corrosion and abrasive environments, while enclosure ratings of IP55 or IP65 safeguard against dust and water ingress, significantly extending the equipments operational life in harsh settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Blower Category

High Pressure Centrifugal Blowers

Application : Industrial Ventilation, Other

Material : other , Metal

Color : Blue

Product Type : Others, High Pressure Centrifugal Blowers

Power Source : Other, Electric Motor

Dimension (L*W*H) : Standard

Belt Driven Centrifugal Fan

Application : Other, Industrial ventilation

Material : other , Mild steel

Color : Gray

Product Type : Belt Driven Centrifugal Fan, Others

Power Source : Other, AC power

Dimension (L*W*H) : Standard industrial size

Gas Blower

Application : Other, Industrial Gas Firing, Combustion Systems, Furnace Air Supply

Material : other , Mild Steel

Color : Silver / Grey

Product Type : Others, Industrial Gas Blower

Power Source : Other, Electric

Dimension (L*W*H) : 600 x 400 x 450 mm

Suction Centrifugal Blowers

Application : Other, Industrial air handling and ventilation

Material : other , Metal

Color : Blue and Green

Product Type : Suction Centrifugal Blowers, Others

Power Source : Electric, Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS