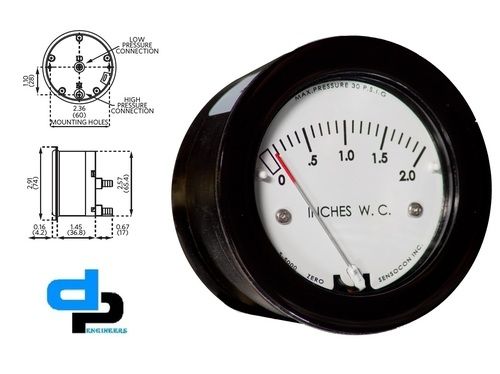

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5010

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5010 Specification

- Bourdon Tube

- Not Applicable (Uses Diaphragm)

- Display

- Analog

- Grade

- Industrial

- Seal Material

- Silicone Rubber

- Sensor Type

- Differential Pressure Gauge

- Outer Size

- Approximately 60 mm Diameter

- Thread

- 1/8 NPT

- Material

- High Impact Plastic Housing

- Dial Material

- ABS Plastic

- Pointer Material

- Aluminum

- Processing Type

- Injection Molded

- Diameter

- Miniature, approx. 60 mm

- Glass Size

- Approx. 43 mm

- Mount Type

- Surface Mount

- Scale Range

- 010 Inch WC (Water Column), various ranges available

- Accuracy

- 2% Full Scale

- Finishing

- Matte Black Housing

- Measure Pressure Of

- Low Differential Air or Non-corrosive Gases

- Accessories

- Mounting Screws Included

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5010 Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- Nagaland, South India, East India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Himachal Pradesh, Jammu and Kashmir, Karnataka, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Kerala, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Maharashtra, Haryana, Delhi, Gujarat, North India, Andhra Pradesh, Central India, Odisha, Jharkhand, West India, Chhattisgarh, All India

About Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5010

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5010

Description

Mounts in Industry Standard Holes

Accuracy 5%

Low-Cost Miniature Size

The Series Sz-5000 is a low cost, diaphragm operated, differential pressure gauge in a miniature housing. The Sz-5000 can be used in applications for measuring positive, negative, or differential pressure with an accuracy of 5%. Standard applications include monitoring filter status, duct static pressure, room pressure, fan or blower pressure, paint booths, dust collectors, and cabinet purging along with many others.

Customizing Options Available

MODEL NUMBERS

| MODEL NUMBERS | Pressure Range |

| Sz-5010 | 0 - 10" |

SPECIFICATIONS

Pressure Limits: 30 PSI (2.067 bar)

Media Compatibility: Air and compatible non-corrosive gasses

Accuracy: +/- 5% full scale throughout range at 70F (21C)

Temperature Ranges: 20 to 120F (-7 to 49C)

Housing Material: Glass-filled nylon, polycarbonate cover

Process Connection: Barbed connections for 3/16" I.D. tubing

Weight: 6 oz (170 g)

Accessories: Two mounting studs and hex nuts, allen wrench, and panel mounting bracket

Agency Approvals: RoHS, CE

Reliable Low Differential Pressure Monitoring

Engineered for precision, the Sz-5010 ensures dependable measurement of air or non-corrosive gas pressure differences. With its silicone rubber seal and injection-molded high-impact plastic housing, it delivers consistent readings ideal for sensitive environments such as clean rooms and medical devices. Its quick response time and 2% full-scale accuracy enhance operational safety and system monitoring efficiency.

Easy Installation and Versatile Connections

Designed for straightforward integration, the Sz-5010 features surface mounting capabilities and includes all necessary mounting screws. Barbed connections accommodate 1/8" or 3/16" ID tubing, or you can utilize the 1/8 NPT threaded option. Its compact, lightweight build ensures minimal space requirement in crowded control panels and equipment setups.

Durable, Compact, and Ready for Harsh Conditions

The gauges tough, matte-black housing resists impact and environmental stress, allowing operation in temperatures ranging from -20C to 60C. The analog dial is shielded by robust ABS plastic and an aluminum pointer, built to withstand industrial and field applications while maintaining a sleek, professional appearance.

FAQs of Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5010:

Q: How is the Sensocon Sz-5010 differential pressure gauge typically installed?

A: The Sz-5010 gauge is surface-mounted using the provided mounting screws. Its compact design and included accessories make installation quick and convenient, particularly in space-constrained applications.Q: What types of pressure does the Sz-5010 measure, and for which applications is it suitable?

A: This gauge is designed to measure low differential pressure of air or non-corrosive gases. It is ideal for HVAC systems, filter monitoring, clean room environments, and medical equipment, offering reliable and precise readings.Q: When should I consider using the Sz-5010 instead of other pressure gauges?

A: Opt for the Sz-5010 when you require an economical, compact, and accurate gauge for low-pressure monitoring in industrial or laboratory settings, especially where rapid response and a miniature footprint are essential.Q: Where can I connect the tubing, and what tube sizes are compatible?

A: The Sz-5010 offers barbed connections suitable for 1/8" or 3/16" inner diameter tubing, as well as a 1/8 NPT threaded option for different installation preferences.Q: What ensures the durability and longevity of the Sz-5010 in demanding conditions?

A: The housing is constructed from high-impact plastics and is finished in matte black to resist scratches and wear. Withstanding temperatures from -20C to 60C and overpressure up to 10 psi, the gauge is suitable for tough industrial environments.Q: How does the Sz-5010 benefit facility monitoring and maintenance?

A: With a rapid response time of under 1 second and 2% full scale accuracy, the gauge enables prompt, precise detection of pressure changes. This supports timely filter replacement, airflow adjustments, and maintains optimal system performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Differential Pressure Gauge Series Sz-5000 sensoco Category

Miniature Low-Cost Differential Pressure Gauge Series Sz- 5000

Display : Analog

Dial Material : Other, Aluminium

Accuracy : 2% of Full Scale

Material : Other, ABS Plastic body, Brass connection

Measure Pressure Of : Other, Air and noncorrosive gases

Finishing : Other, Powder coated

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-3KPA

Display : Analog

Dial Material : Other, Aluminum with Printed Scale

Accuracy : 2% of Full Scale

Material : Other, ABS Plastic (Body), Acrylic (Window)

Measure Pressure Of : Other, Air and Noncorrosive Gases

Finishing : Other, ABS Plastic Housing

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5003

Display : Analog

Dial Material : Other, Aluminum

Accuracy : 2% of Full Scale

Material : Other, ABS Plastic Housing

Measure Pressure Of : Other, Air and NonCorrosive Gases

Finishing : Other, Textured Black

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-500PA

Display : Analog

Dial Material : Plastic

Accuracy : 2% of Full Scale

Material : Other, ABS Plastic Housing

Measure Pressure Of : Other, Air and NonCorrosive Gases

Finishing : Other, White & Blue Plastic Body

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS