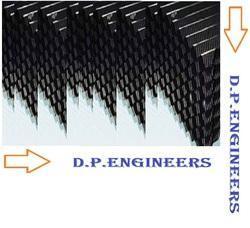

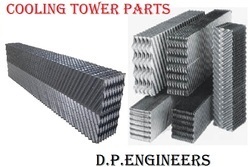

PVC Fill

PVC Fill Specification

- Material

- PVC (Polyvinyl Chloride)

- Application

- Cooling towers, water treatment

- Condition

- New

- Type

- Cooling Tower Fill / PVC Fill Pack

- Dimension (L*W*H)

- 1200mm x 300mm x 600mm (typical)

- Cooling Type

- Water Cooling

- Water Flowing Rate

- Suitable for high and low velocity water

- Noise Control

- Low noise (dependent on system)

- Installation Method

- Stackable, easy to fit

- Design Pattern

- Honeycomb / Wave fill structure

- Service Life

- 5+ years under normal conditions

- UV Resistance

- UV stabilized PVC

- Heat Resistance

- Up to 60°C

- Sheet Thickness

- 0.28 mm to 0.35 mm

- Packing Density

- High efficiency, custom options

- Usage Environment

- Industrial, commercial cooling towers

- Flute Height

- 19 mm (typical)

- Surface Area

- Approx. 150 m²/m³

- Fire Retardant

- Optional

- Maintenance

- Easy to clean and replace

- Color

- Black / Blue / Grey

About PVC Fill

PVC Fill

WE, D.P. Engineers are market leader in providing a wide range of PVC Fills. These PVC Fills are made of very good quality raw material so there acceptance in market depends mainly because of this superior Quality.

Efficient Cooling Performance

Designed for maximum thermal exchange, these PVC fills enhance water cooling efficiency by offering a high surface area (approx. 150 m/m). The unique flute height of 19 mm and optimized design patterns facilitate both high and low water velocity applications, ensuring versatile use in diverse cooling tower systems across industries.

Durable and Easy to Maintain

Constructed from UV-stabilized, fire-retardant (optional) PVC, these fills promise robust performance with a service life extending over five years under normal operation. Their easy-to-clean structure, coupled with the replacement-friendly design, minimizes downtime and simplifies upkeep for both industrial and commercial setups.

Flexible Installation and Customization

Each fill pack is stackable and simple to install, allowing seamless integration into new or existing cooling tower frameworks. We offer bespoke sizing and densities to meet different project requirements, ensuring that clients enjoy tailored performance and efficiency enhancements for their specific needs.

FAQs of PVC Fill:

Q: How are PVC Fills installed in a cooling tower system?

A: PVC Fill packs are designed for straightforward stacking and fitting within the designated sections of a cooling tower. Their modular design allows installers to quickly assemble or replace fills without specialized tools, streamlining both initial installation and future maintenance routines.Q: What benefits do honeycomb and wave patterns offer in these PVC Fills?

A: The honeycomb and wave fill structures maximize water-air contact, enhancing the cooling efficiency and promoting uniform water distribution. This design not only boosts heat exchange but also helps maintain low operational noise levels, supporting a quieter cooling environment.Q: When should the PVC Fills be replaced or cleaned?

A: Regular inspection is advised; typically, a fill pack should be cleaned when theres visible scale, debris build-up, or reduced water flow. Under normal conditions, these PVC Fills last over five years, but harsh operating environments might necessitate earlier replacement or more frequent cleaning.Q: Where can these PVC Fill packs be effectively used?

A: These PVC Fill packs are suitable for industrial and commercial cooling towers, including facilities involved in water treatment and climate control applications. Their high efficiency and adaptability make them suitable for various new constructions or as a retrofit solution in existing towers.Q: What is the process to customize PVC Fill dimensions and packing density?

A: Clients can specify their required dimensions, colors, or packing densities at the time of order. Our in-house manufacturing enables tailored production to meet unique project specifications, ensuring the fills cater to varying flow rates and cooling demands.Q: How does the products UV stability and fire retardancy enhance its performance?

A: UV-stabilized PVC resists sunlight degradation, extending the products functional life even in outdoor settings. Optional fire-retardant composition bolsters safety, making these fills suitable for compliance with stringent industrial standards.Q: What advantages does using PVC Fill offer for noise control in cooling towers?

A: Thanks to the structural pattern and high-quality PVC material, these fills contribute to effective noise suppression, helping maintain a quieter operationan advantage especially relevant for installations close to populated or noise-sensitive areas.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cooling Tower Spare Parts Category

GUN Type

Material : Other , Mild Steel Body

Type : Gun Type Air Cooler

Condition : New

Application : Industrial and Commercial Use

Dimension (L*W*H) : 1500 x 700 x 1300 mm

Water Flowing Rate : 90 L/h

Honeycomb Panel

Material : Other , Aluminum Honeycomb Core with Aluminum Face Sheets

Type : Honeycomb Panel

Condition : New

Application : Building Facades, Wall Claddings, Ceilings, Partitions, Furniture

Dimension (L*W*H) : Customized as per requirement

Water Flowing Rate : Optimal for Maximum Cooling

Honeycomb Type Pvc Fill

Material : Other , PVC (Polyvinyl Chloride)

Type : Honeycomb PVC Fill

Condition : New

Application : Cooling Tower, Industrial Cooling

Dimension (L*W*H) : Customized, Common sizes: 600mm x 300mm x 150mm, 1000mm x 300mm x 150mm

Water Flowing Rate : Customized, as per requirement

Aluminum Fan Cooling Tower

Material : Aluminum

Type : Cooling Tower Fan

Condition : New

Application : Cooling Tower

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS