Pleated Metal Mesh Filter

Pleated Metal Mesh Filter Specification

- Filtration Grade

- Medium to Fine

- Temperature Range

- -20C to 300C

- Media Type

- Wire Mesh

- Flow Rate

- 50-1000 m3/h (Depends on size and application)

- Filter Type

- Pleated Metal Mesh Filter

- Cleaning Method

- Washable/Reusable

- Efficiency (%)

- Up to 99%

- Pressure

- Up to 8 bar

- Connecting Type

- Flanged or threaded

- Capacity

- Custom (Based on requirement)

- Condition

- New

- Material

- Stainless Steel Mesh

- Mesh

- Multiple mesh sizes available

- Diameter

- Customizable (Typically 50-300 mm)

- Construction

- Pleated cylindrical or panel

- Medium Filter

- Metal Mesh

- Weight

- Variable (Depends on size and specification)

- Shape

- Cylindrical/Pleated

- Feature

- High dirt holding capacity, Long service life, Washable and reusable, Corrosion resistant

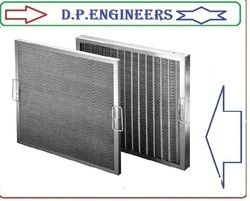

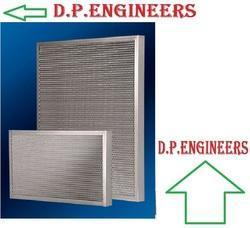

About Pleated Metal Mesh Filter

Pleated Metal Mesh Filter

Pleated Metal Mesh Filter are Pre Filters that are designed for general ventilation and Air Conditioning System applications as well as for electric motors and plenum air for working areas. These are an economical and a very durable option over other pre filter counterparts.

Construction: The element is constructed using 5 layer of GI Wire mesh inter spaced with 2 crimpled layers and 3 flat layers. The media is supported with expanded metal from both sides as reinforcement and housed usually in deep metal frame (custom build sizes are also available on order).

Specification Efficiency

Standard Pleated Metal Mesh Filter have an efficiency of 65% for 20 micron size particles. Metallic filters with an efficiency rating of 65-85% to capture 25 micron to 50 micron size particles are also available on order. Efficiency can be increased to 85% if the filters are oil wetted.

- Frame Type : Available in Flange or Box Type GI,AL.,SS.

- Filter media : GI/SS/Aluminum expanded mesh

- Face guard : Filter is protected with expanded mesh on both sides

- Pressure drop :Initial pressure drop ~1mm wg & recommended final pressure drop is 5-10mm wg

Operating conditions

Filter can withstand temperature >80ºc and relative humidity of 70%. Recommended air velocity is 2m/sec to 2. 5m/sec. Filter is washable and can be washed using water or back air pressure and reused.

Application

Pleated Metal Mesh Filter are most suited for:

Air Handling Units (AHU),

- Automatic Drain Holes,

- Paint Shops,

- Textile Mills,

- Cement Factories,

- Miscellaneous Industrial Ventilation.

Superior Filtration for Multiple Industries

Designed to meet the demands of HVAC, oil and gas, petrochemical, and water treatment processes, our Pleated Metal Mesh Filter caters to clients seeking durable and efficient filtration solutions. With a customizable diameter and a wide selection of mesh sizes and micron ratings, it ensures precise particle removal for a variety of industrial requirements.

Engineered for Durability and Reliability

Crafted with corrosion-resistant stainless steel mesh and robust end cap and frame materials, this filter can handle challenging environments. The available gaskets (EPDM, nitrile, silicone) and advanced build allow for installation in either vertical or horizontal orientations. Each unit delivers a high dirt holding capacity, supporting extended operational cycles and reduced maintenance.

Cost-Effective and Easy Maintenance

By choosing our washable and reusable filters, users benefit from a longer service life and notable savings on replacements. These filters support flow rates from 501000 m3/h and can be tailored to suit your systems capacity and process needs. Simple to clean and reinstall, they ensure continuous filtration efficiency and low downtime.

FAQs of Pleated Metal Mesh Filter:

Q: How do I select the appropriate Pleated Metal Mesh Filter for my application?

A: Begin by assessing your systems flow rate, required micron rating, pressure, temperature, and the specific contaminants you wish to remove. Provide your size or drawing during ordering, and select compatible frame, end cap, and gasket materials based on your applications environment and temperature range.Q: What is the cleaning and maintenance process for these filters?

A: The filters are designed to be washable and reusable. When the pressure drop reaches the maximum recommended differential (25 bar), remove and clean the mesh using water, mild detergent, or air-blowing methods, depending on the contaminant type. Ensure the filter is fully dry before reinstalling.Q: When should I replace my Pleated Metal Mesh Filter?

A: Service life is up to two years but depends on operating conditions, contaminant load, and cleaning frequency. Inspect filters regularly for signs of physical damage, excessive clogging, or reduced filtration efficiency, and replace when cleaning no longer restores performance.Q: Where can I install these filters in my system?

A: They are suitable for both vertical and horizontal installation within HVAC systems, process pipelines, or equipment requiring medium to fine filtration. Customizable connecting types (flanged or threaded) allow integration into existing or new systems with minimal modifications.Q: What are the advantages of using a pleated design in metal mesh filters?

A: The pleated construction increases the surface area for dust and particle capture, resulting in higher dirt holding capacity, improved flow rates (up to 1000 m3/h), and longer intervals between cleaning or replacement compared to flat panel filters.Q: What benefits do stainless steel construction and corrosion-resistant features offer?

A: Stainless steel mesh and frames offer excellent resistance to corrosion, extending filter longevity and ensuring consistent performance even under harsh conditions involving moisture, chemicals, or varying temperatures (-20C to 300C).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Filter Category

Metallic Filters

Shape : Round

Material : Stainless Steel / Mild Steel

Filter Type : Mesh/Cartridge Type

Construction : Other, Rugged metallic mesh construction

Condition : New

Feature : High filtration efficiency, durable structure

Fresh Air Filter

Shape : Rectangular or customized shapes

Material : Galvanized Iron, Aluminum, Stainless Steel (options available)

Filter Type : Fresh Air Pre Filter

Construction : Other, Robust frame with supported mesh layers

Condition : New

Feature : High dust holding capacity, Excellent filtration efficiency, Rust resistant matrix, Easy installation, Durable structure

Wire Mesh Filter

Shape : Round

Material : Stainless Steel

Filter Type : Wire Mesh Disc Filter

Construction : Other, Single Layer/Multiple Layer Welded Mesh

Condition : New

Feature : Corrosion Resistant, Durable Filtration, Precise Pore Size, Easy Installation

Dry Viscous Metallic Air Filters

Shape : Rectangular

Material : Metal

Filter Type : Dry Viscous Metallic Air Filter

Construction : Metallic Frame, Other

Condition : New

Feature : Durable and Resilient

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS