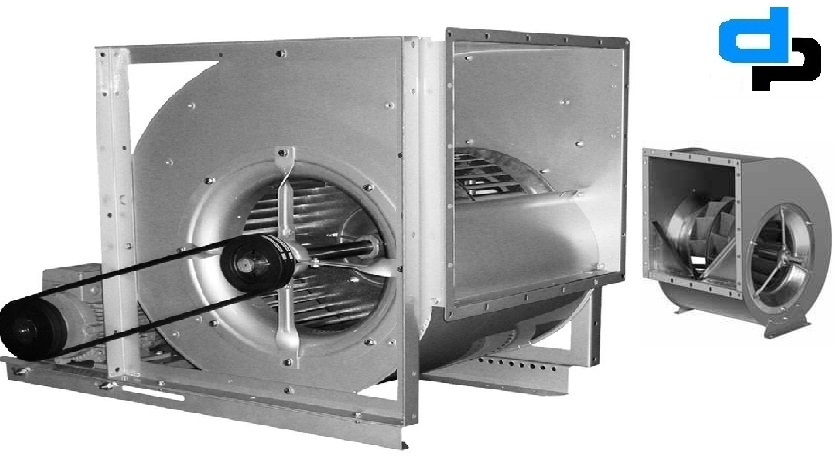

Nicotra Backward Curved Centrifugal Fan RDH 1000 K

Nicotra Backward Curved Centrifugal Fan RDH 1000 K Specification

- Pressure Range

- 500-2000 Pa

- Life Span

- 10 years

- Output Power

- 7.5 kW

- Flow Rate

- up to 37000 m/h

- Max Pressure

- 2000 Pa

- Power

- 7.5 kW

- Motor Power

- 7.5 kW

- Product Type

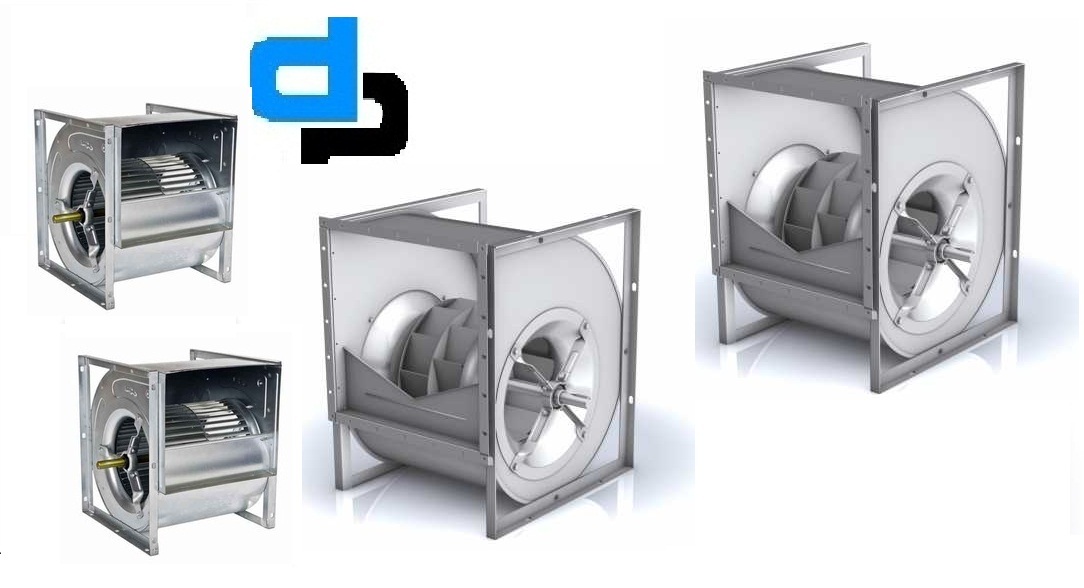

- Backward Curved Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- up to 37000 m/h

- Pressure

- 2000 Pa

- Application

- Ventilation, HVAC, Industrial Exhaust, Air Handling Systems

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1450 RPM

- Noise Level

- 75 dB (A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- 180 kg

- Dimension (L*W*H)

- 1200 x 1100 x 1100 mm

- Color

- Grey

Nicotra Backward Curved Centrifugal Fan RDH 1000 K Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Tripura, Manipur, Meghalaya, Andaman and Nicobar Islands, Pondicherry, South India, Central India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Uttar Pradesh, Delhi, Daman and Diu, Goa, Jammu and Kashmir, Jharkhand, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Uttarakhand, Dadra and Nagar Haveli, Lakshadweep, Haryana, Gujarat, Odisha, Karnataka, All India

About Nicotra Backward Curved Centrifugal Fan RDH 1000 K

Nicotra Backward Curved Centrifugal Fan RDH 1000 K

| Product | RDH 1000 K |

| Brand | Nicotra |

| Description | Extractor Fan |

| Condition | New |

Find Cheap Spare Parts For Machines Using The Products of Nicotra.Our Team of Experts Will Find the Best Sales Prices For Products of Nicotra - RDH 1000 K Extractor Fan in USA.Using the Products of Nicotra Will Minimize Your Costs On Spare Parts.Our Job Is To Save You Time And Minimize Your Expenses On Spare Parts And Industrial Components.Our Company Is Not An Official Distributor of Nicotra, But We Are Selling Their Products At Competitive Prices.Purchase High Quality Spare Parts of Nicotra - RDH 1000 K Extractor fan in INDIA on Cheap Prices.With Each Day We Gain More and More Experience and That's Why We Are Able to Satisfy Your Needs For Spare Parts.

Reliable Performance for Industrial Environments

Designed to withstand tough operating conditions, the RDH 1000 K fan operates efficiently between -20C and +60C. Its powder-coated galvanized steel housing and aluminium blades provide exceptional durability, making it suitable for a wide range of commercial and industrial ventilation systems.

High-Efficiency Direct Drive System

This centrifugal fan features a direct-driven, single-stage motor that offers consistent airflow at 1450 RPM, achieving up to 37,000 m/h. The direct drive system minimizes energy loss, while sealed-for-life bearings reduce the need for routine maintenance, supporting continuous, trouble-free operation.

Safety and Longevity Built-In

With IP55 ingress protection and F class insulation, the RDH 1000 K is engineered for safety and long service lifeover 10 years in standard applications. Its maintenance-free configuration ensures optimal reliability, even in demanding environments such as industrial exhaust and HVAC installations.

FAQs of Nicotra Backward Curved Centrifugal Fan RDH 1000 K:

Q: How does the Nicotra Backward Curved Centrifugal Fan RDH 1000 K improve ventilation systems?

A: The RDH 1000 K enhances ventilation by delivering high flow rates up to 37,000 m/h and pressures up to 2000 Pa. Its backward curved impeller optimizes air movement efficiency, making it ideal for air handling, HVAC, and industrial exhaust applications.Q: What are the key benefits of the backward curved impeller design?

A: Backward curved impellers provide higher efficiency and lower noise levels compared to forward-curved types. This design helps the fan handle high pressures and minimizes the risk of dust accumulation, contributing to quieter operation and reduced maintenance.Q: When is this fan typically used in industrial settings?

A: The RDH 1000 K is commonly deployed in areas requiring significant airflow, such as factories, warehouses, and facilities with complex HVAC or industrial exhaust requirements. It is well-suited for applications that demand robust, reliable air movement with minimal maintenance.Q: Where can this fan be installed?

A: Thanks to its base-mounted design and compact dimensions (1200 x 1100 x 1100 mm), the fan can be installed in a variety of locationsmechanical rooms, rooftop units, or directly integrated into ventilation ductsdepending on the systems needs.Q: What maintenance is required for the RDH 1000 K fan?

A: This fan features sealed-for-life bearings and a maintenance-free configuration. Routine inspection is recommended to ensure system integrity, but regular bearing lubrication or replacement is not necessary, simplifying upkeep.Q: How does the fan withstand challenging environments?

A: The fans powder-coated galvanized steel housing provides corrosion resistance, while its IP55 ingress protection safeguards against dust and water. Combined with F class insulation and a wide temperature range, the RDH 1000 K operates reliably in harsh industrial and commercial environments.Q: What are the power requirements and operational capacity of this fan?

A: Operating at 415 V, 7.5 kW, with a 1450 RPM motor, the fan is designed for standard industrial electric power grids in India. It offers reliable air movement with a pressure range of 5002000 Pa, meeting the demands of large-scale ventilation systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series RDH Nicotra Backard Curved Centrifugal Fan- Category

Nicotra Backward Curved Centrifugal Fan RDH 900 K

Price 175000.00 INR

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Voltage : 380415 V

Frequency (MHz) : 50 Hz

Product Type : Others, Backward Curved Centrifugal Fan

Nicotra Backward Curved Centrifugal Fan RDH 180 R

Price 18000 INR

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Voltage : 230 V AC

Frequency (MHz) : 50 Hz

Product Type : Others, Backward Curved Centrifugal Fan

Nicotra Backward Curved Centrifugal Fan RDH 315 R

Price 27000.00 INR

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Voltage : 415 V

Frequency (MHz) : 50 Hz

Product Type : Others, Backward Curved Centrifugal Fan

Nicotra Backward Curved Centrifugal Fan RDH 1400 X1

Price 6500 INR / Piece

Minimum Order Quantity : 10 Pieces

Power Source : Electric Blower

Voltage : 210/415 Volt(v)

Frequency (MHz) : 50/60 Hertz(Hz)

Product Type : Others, Exhaust Air Blower

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS