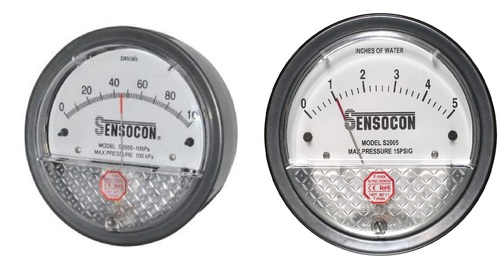

Front Mount Differential Pressure Gauge

Front Mount Differential Pressure Gauge Specification

- Outer Size

- 110 mm x 45 mm approx.

- Seal Material

- Nitrile Rubber

- Bourdon Tube

- Stainless Steel Bourdon Tube

- Grade

- Industrial Grade

- Display

- Analog

- Thread

- 1/2 BSP Male

- Sensor Type

- Differential Pressure Sensor

- Material

- Stainless Steel

- Dial Material

- Aluminum, White Powder Coated

- Pointer Material

- Aluminum, Black Painted

- Processing Type

- Machined

- Diameter

- 100 mm

- Glass Size

- 100 mm

- Mount Type

- Front Mount

- Scale Range

- 0 4000 mmWC

- Accuracy

- 2% F.S.

- Finishing

- Powder Coated

- Measure Pressure Of

- Gas, Liquid

- Accessories

- Mounting Bracket

- Zero Adjustment

- Accessible from Front

- Dial Graduation

- Single or Dual Scale

- Maximum Working Pressure

- 20 bar

- Application

- Filter Monitoring, Level Measurement, Flow Systems

- Enclosure Rating

- IP65

- Case Material

- Die Cast Aluminum

- Window Material

- Clear Acrylic

- Connection Location

- Back/Bottom

- Operating Temperature Range

- -20°C to +70°C

Front Mount Differential Pressure Gauge Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- Tripura, Manipur, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Rajasthan, Sikkim, Tamil Nadu, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Haryana, Delhi, Gujarat, North India, Punjab, Telangana, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About Front Mount Differential Pressure Gauge

The Series S1000 Front Mount Differential Pressure Gauge makes panel mounting quick and easy. The S1000 is a diaphragm operated gauge for measuring positive, negative, or differential pressure. The S1000 was designed to allow quick installation saving time and money. This includes easy front mounting with 4 screws without any additional hardware required, and quick tubing connections with molded-in pressure fittings. The Series S1000 Front Mount Differential Pressure Gauge has a span adjustment on the back of the gauge for calibration adjustments. In addition to the time savings offered by the Series S1000 Differential Pressure Gauge, the gauge is based on the same rugged design as the S2000, which allows for years of trouble free operation.

Pressure Limits:

- -20 Hg to 15 PSI (-0.677 bar to 1.034 bar)

- Media Compatibility:

- Air and compatible gasses

- +/- 2% full scale (+/- 3% on -0 and +/- 4% on -00) throughout range at 70°F (21°C)

- Temperature Ranges:

- 20° to 140°F (-7° to 60°C)

- Housing Material:

- Die cast aluminum case with ABS flange and acrylic cover

Duplicate high and low recessed, push on connections for 3/16 tubing one pair side and one pair back

Weight:

1 lb 2 oz (510 g)

Accessories:

2 connection plugs, 4 mounting screws, 4 screw caps, 2 static pressure connectors, and 3 feet of vinyl tubing

Agency Approvals:

Versatile Industrial Pressure Monitoring

Designed with industrial-grade components, this differential pressure gauge supports applications such as filter monitoring, level measurement, and flow system analysis. The robust powder-coated, machined stainless steel construction ensures resistance to harsh environments, and the precision analog display provides reliable pressure readings for both gases and liquids.

User-Friendly Design and Installation

Installation is straightforward with front mounting and optional bottom or back connection locations. The 1/2 BSP male thread and included mounting bracket facilitate secure attachment, while the accessible zero adjustment on the front ensures easy calibration. The clear, acrylic window and white powder coated dial improve visibility and usability in demanding operational settings.

FAQs of Front Mount Differential Pressure Gauge:

Q: How is zero adjustment performed on the differential pressure gauge?

A: Zero adjustment can be accessed directly from the front of the gauge, enabling quick and accurate calibration without disassembly, ensuring precise measurements for varying operational requirements.Q: What materials are used in the construction of this pressure gauge?

A: This gauge features a die cast aluminum case, a clear acrylic window, a stainless steel Bourdon tube, aluminum dial and pointer, and nitrile rubber seals, providing robust protection and lasting performance in industrial applications.Q: Where is the connection location situated on the pressure gauge?

A: The connection for this gauge is located on the back or bottom, allowing flexible installation options depending on the system setup and convenience.Q: What process is the gauge manufactured by and what are its finishing details?

A: The gauge undergoes precision machining, resulting in exact dimensions and quality. Its outer components are powder coated for increased surface protection against corrosion and wear in harsh industrial environments.Q: What is the benefit of the IP65 enclosure rating for this gauge?

A: With an IP65 enclosure rating, the gauge offers excellent protection against dust ingress and water jets, making it suitable for use in challenging industrial settings where durability and reliability are crucial.Q: When should this differential pressure gauge be used?

A: This gauge is best used for monitoring differential pressure in filter systems, tracking levels in tanks, and managing flow rates in industrial processes involving gases and liquids, especially where high accuracy and rugged construction are required.Q: What is the scale range of the dial and what does 2% F.S. accuracy indicate?

A: The dial scale ranges from 0 to 4000 mmWC, accommodating a wide variety of measurement needs. The 2% F.S. (Full Scale) accuracy means readings will be within 2% of the gauges maximum scale value, ensuring reliable data for process control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SENSOCON Differential Pressure Gauges Dealers Wholesaler for Delhi|NCR|India|Faridabad|Noida|Ghaziabad|Gurgaon|Bulandshahr|Ballabhgarh|Bahadurgarh|Dehradun|Haridwar|Udham Singh Nagar Category

Sensocon Make Differential Pressure Gauge Near Dhenkanal Odisha

Minimum Order Quantity : 25 Pieces

Display : Analog

Finishing : Antique, Polished, Galvanized, Matte

Diameter : 4 inch / 100 Millimeter (mm)

Accuracy : +2% of full span at 70 (21 (+3% on 0, and +4% on 00) %

Scale Range : MM WC/ CM / PAC / KPA / INCH / PSI / MBAR

Sensocon Make Differential Pressure Gauges in Wholesale Dealers Suppliers Distbutors Peeragarhi

Minimum Order Quantity : 50 Pieces

Display : Analog

Finishing : Antique, Polished, Galvanized, Matte

Diameter : 4 inch / 100 Millimeter (mm)

Accuracy : 2% of full span at 70 (21 (3% on 0, and 4% on 00) %

Scale Range : MM WC/ CM / PAC / KPA / INCH

Low Cost Sensocon Differential Pressure Gauge

Display : Analog

Finishing : Other, Matte Black

Diameter : 110 mm

Accuracy : 2% of Full Scale

Scale Range : 060 Pa, 0250 Pa, 0500 Pa, 01 kPa, 02.5 kPa, 05 kPa (multiple options available)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS