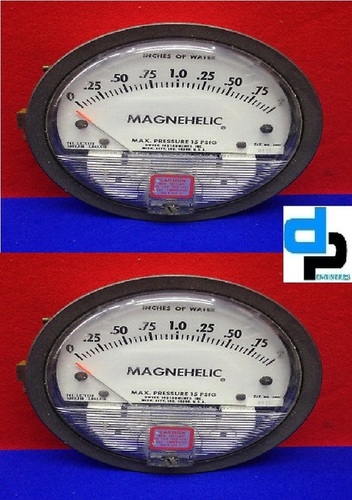

Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC

Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC Specification

- Display

- Analog

- Outer Size

- 4 (101.6 mm) diameter

- Seal Material

- Silicone rubber

- Thread

- 1/8 NPT

- Sensor Type

- Diaphragm

- Grade

- Industrial

- Material

- Die-cast aluminum case and bezel

- Dial Material

- Fire-retardant plastic

- Pointer Material

- Aluminum

- Processing Type

- Factory calibrated

- Diameter

- 4 inches

- Glass Size

- 4 inches

- Mount Type

- Surface or flush mount

- Scale Range

- 0-2.0 Inch WC

- Accuracy

- 2% of full scale

- Finishing

- Textured grey finish

- Measure Pressure Of

- Low differential air and non-corrosive gases

- Accessories

- Two 1/8 NPT plugs, two surface mounting brackets, and four screws

Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Manipur, Uttarakhand, South India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Daman and Diu, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Lakshadweep, Delhi, Gujarat, Kerala, Central India, Chhattisgarh, All India

About Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC

Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC Filter Monitoring

Air Velocity with Dwyer Pitot Tube

Blower Vacuum Monitoring

Fan Pressure Indication

Duct, Room or Building Pressures

Clean Room Positive Pressure Indication

Select theMagnehelic Gagefor high accuracy--guaranteed within 2% of full scale--and for the wide choice of models available to suit your needs precisely. Using Dwyer's simple, frictionlessMagnehelic Gagemovement, it quickly indicates low air or non-corrosive gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. It's inexpensive, too.

TheMagnehelic Gageis the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Specifications

Service:Air and non-combustible, compatible gases (Natural Gas option available).

Housing:Die cast aluminum case and bezel, with acrylic cover. Exterior finish is coated gray to withstand 168 hour salt spray corrosion test.

Accuracy:±2% of full scale throughout range at 70°F (21.1°C).

Pressure Range:0-1.0" w.c.

Pressure Limits:-20" Hg. to 15 psig. (-0.677 bar to 1.034 bar).

Overpressure:Relief plug opens at approximately 25 psig (1.72 bar), standard gages only.

Temperature Limits:20 to 140°F (-6.67 to 60°C).

Mounting Orientation:Diaphragm in vertical position.

Process Connections:1/8" female NPT duplicate high and low pressure taps - one pair side and one pair back.

Weight:1 lb 2 oz (510 g).

Standard Accessories:Two 1/8" NPT plugs for duplicate pressure taps, two 1/8" pipe thread to rubber tubing adapters and three flush mounting adapters with screws.

Reliable Differential Pressure Measurement

The Dwyer 2002 Magnehelic Gage delivers consistent and accurate monitoring of low differential pressures as low as 0 up to 2.0 Inch WC. Factory calibration and robust diaphragm sensor technology ensure that your measurements remain dependable and repeatable, making it the trusted choice for a wide range of HVAC and clean room applications.

Versatile Installation Options

With its 4-inch diameter and lightweight design, this gage offers flexible mounting options either flush or surface mount and includes all necessary accessories for convenient installation. Its back connection location, user-adjustable zero, and compatibility with various mounting orientations accommodate unique industrial setups while supporting accuracy.

Durability & User-friendly Design

Housed in a die-cast aluminum case with a clear acrylic window, the Dwyer 2002 is built for durability and long-term reliability in rugged environments. Features such as the external zero adjustment screw and fire-retardant plastic dial simplify maintenance and operation, while the textured grey finish adds a professional look to industrial panels.

FAQs of Dwyer USA 2002 Magnehelic Gage Range 0-2.0 Inch WC:

Q: How is the Dwyer 2002 Magnehelic Gage installed?

A: The Dwyer 2002 Magnehelic Gage can be surface or flush mounted using the provided mounting brackets and screws. All required accessories, such as NPT plugs, are included with the product, making installation straightforward on most panels or walls.Q: What media can the Magnehelic Differential Pressure Gage measure?

A: This gage is designed specifically to measure low differential pressures of air and non-corrosive gases. It is not recommended for use with liquids or corrosive environments.Q: When should I use the zero adjustment feature?

A: The external zero adjustment screw should be used when calibrating the gage or if the pointer drifts from zero under no pressure conditions, ensuring ongoing accuracy for sensitive measurements.Q: Where can this pressure gage be used?

A: It is suitable for various industrial environments including filter monitoring, fan and blower systems, clean room pressure control, duct static pressure, furnace draft, building pressure, and air velocity measurement.Q: What is the process for reading and maintaining this gage?

A: Pressure readings are sensed by a diaphragm and displayed immediately on a clear analog dial. Maintenance is minimal, primarily involving occasional calibration checks using the zero adjustment, and keeping the acrylic window clean for unobstructed viewing.Q: How does the Magnehelic ensure accuracy and reliability?

A: The gage is factory calibrated for 2% full scale accuracy and features real-time response, 0.1% repeatability, and robust overpressure protection up to 15 PSIG, all in a durable die-cast aluminum housing.Q: What are the key benefits of using the Dwyer 2002 Magnehelic Gage?

A: Users benefit from reliable low-pressure measurement, easy installation and adjustment, robust construction, real-time analog response, and long-term durability even in demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Pressure Gauge Category

Dwyer 2000-750PA Magnehelic Differential Pressure Gauge

Price 4500 INR

Minimum Order Quantity : 5 Pieces

Finishing : Other, DieCast Aluminum, Black

Measure Pressure Of : Other, Air and Noncorrosive Gases

Dwyer 2050D Magnehelic Differential Pressure Gauge

Price 9871014210 INR

Minimum Order Quantity : 10 Pieces

Measure Pressure Of : Steam, Oil, Gas

Dwyer 2001D Magnehelic Differential Pressure Gauge

Price 9871014210 INR

Minimum Order Quantity : 10 Pieces

Finishing : Matte, Polished

Dwyer 2010-AV Magnehelic Differential Pressure Gauge

Price 9871014210 INR

Minimum Order Quantity : 10 Pieces

Measure Pressure Of : Steam, Oil, Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS