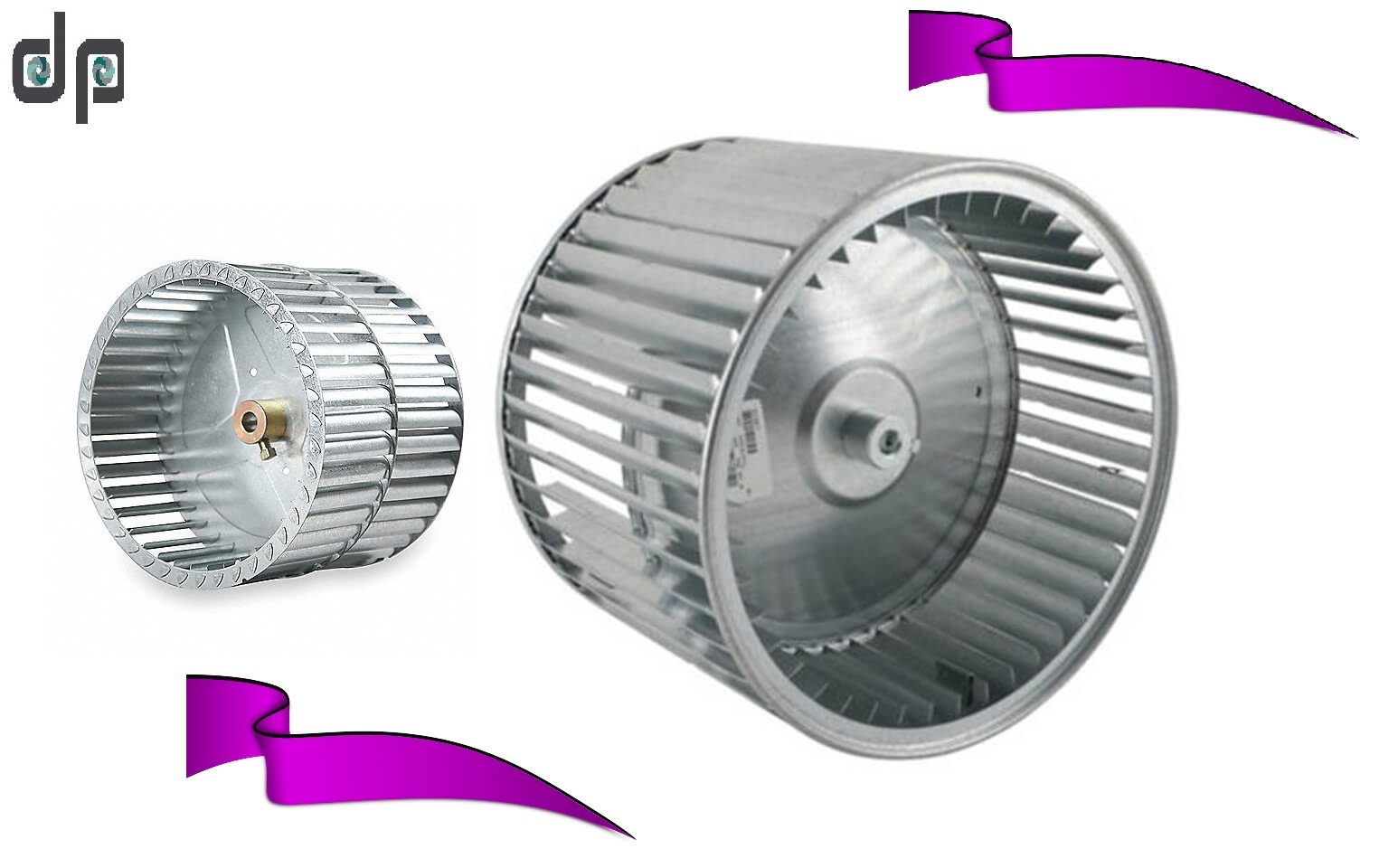

DIDW Centrifugal Fan 230 MM X 152 MM

DIDW Centrifugal Fan 230 MM X 152 MM Specification

- Motor Power

- 1 HP

- Power

- 0.75 kW

- Pressure Range

- 60 to 85 mm WG

- Output Power

- 0.75 kW

- Life Span

- More than 5 years

- Flow Rate

- 900 CFM

- Max Pressure

- 85 mm WG

- Product Type

- DIDW (Double Inlet Double Width) Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- 900 CFM

- Pressure

- Up to 85 mm WG

- Application

- Ventilation, Exhaust, HVAC, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2900 RPM

- Noise Level

- below 85 dB

- Power Source

- Electric

- Voltage

- 230 V

- Weight

- Approx 7 kg

- Dimension (L*W*H)

- 230 mm x 152 mm (Diameter x Width)

- Color

- Silver Grey

DIDW Centrifugal Fan 230 MM X 152 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Nagaland, All India, South India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Haryana, Gujarat, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, Himachal Pradesh

About DIDW Centrifugal Fan 230 MM X 152 MM

DIDW Centrifugal Fan 230 MM X 152 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 31 | DP 9 60 | 230 X 152 X 190 | 9 X 6 | 12.70 (1/2) & 15 MM | AL. / GI. |

Efficient Air Flow

With a double inlet, double width design, the forward curved impeller and 16 blades enable maximum air movement, efficiently supporting ventilation and air handling units. This configuration allows the fan to deliver 900 CFM capacity under variable pressure ranges, ensuring optimal performance for clean or dust-laden air.

Sturdy Construction

The fan is manufactured from powder-coated galvanized steel and features a mild steel shaft. This construction boosts durability and corrosion resistance, ensuring long-term reliability even in demanding environments. The silver grey finish adds to its professional appearance while underlining its industrial strength.

Low Maintenance & Long Life

Designed for minimal maintenance, the DIDW centrifugal fan is easy to service and offers a prolonged lifespan of over five years. Its efficient and reliable operation means lower downtime and reduced total cost of ownership for users, making it suitable for continuous use in vital air movement systems.

FAQs of DIDW Centrifugal Fan 230 MM X 152 MM:

Q: How is the DIDW Centrifugal Fan installed?

A: The fan comes as a base-mounted unit, making installation straightforward on flat surfaces in ventilation, exhaust, or HVAC systems. Follow the manufacturers mounting guide, ensure electrical connections match the 230 V/50 Hz specification, and verify proper alignment for optimal performance.Q: What are the key benefits of using a forward curved impeller in this fan?

A: Forward curved impellers enhance static pressure and airflow, making them highly effective for moving both clean and dust-laden air. This design, paired with 16 blades, ensures efficient operation at 900 CFM capacity and is ideal for applications requiring steady and quiet performance.Q: When should this centrifugal fan be used in HVAC systems?

A: The DIDW Centrifugal Fan is best deployed in situations demanding strong, reliable airflow, such as air handling units, exhaust, and general ventilation. Its double inlet, double width profile handles higher air volumes efficiently, making it suitable for both fresh air and re-circulation needs.Q: Where can this fan be applied for optimal results?

A: Ideal for industrial and commercial environments, the fan suits applications in ventilation ducts, exhaust systems, HVAC units, and air handling machinery. Its robust build and low noise operation also make it suitable for public or workspace installations where quiet efficiency is valued.Q: What is the recommended maintenance process for this fan?

A: Routine maintenance involves periodic inspection and cleaning to prevent dust buildup on blades and checking for any alignment or electrical issues. Lubrication of bearings, when needed, and monitoring for unusual vibrations or sound ensure optimal performance and longevity.Q: How does the fans design contribute to safety and smooth operation?

A: The powder-coated GI sheet frame and mild steel shaft provide enhanced durability and corrosion resistance. The direct-driven design reduces mechanical complexity, leading to fewer mechanical failures, while the low noise output helps maintain a safe and comfortable working environment.Q: What are the energy and operational benefits of using this specific fan model?

A: Operating at 0.75 kW output and 1 HP motor power, the fan ensures economical electricity consumption for its airflow capacity. Its efficient motor speed of 2900 RPM, combined with low maintenance needs and a lifespan exceeding five years, provides long-term operational value for users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 178 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Dimension (L*W*H) : 250 mm x 178 mm x 250 mm

Life Span : More than 5 Years

Power Source : Other, Electric

Pressure : Other, Up to 50 mm WG

DIDW Centrifugal Fan 200 MM X 127 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Dimension (L*W*H) : 200mm x 127mm

Life Span : 10,000 Operating Hours

Power Source : Other, Electric

Pressure : Other, Up to 50 mmWG

DIDW Centrifugal Fan 280 MM X 150 MM

Price 3000 INR

Minimum Order Quantity : 5 Pieces

Dimension (L*W*H) : 280 mm x 150 mm x 180 mm

Life Span : 810 Years

Power Source : Other, Electric

Pressure : Other, 350 Pa

DIDW Centrifugal Fan 180 MM X 178 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Dimension (L*W*H) : 180 mm x 178 mm x 120 mm

Life Span : >40,000 Hours

Power Source : Other, Electric

Pressure : Other, 350 Pa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS