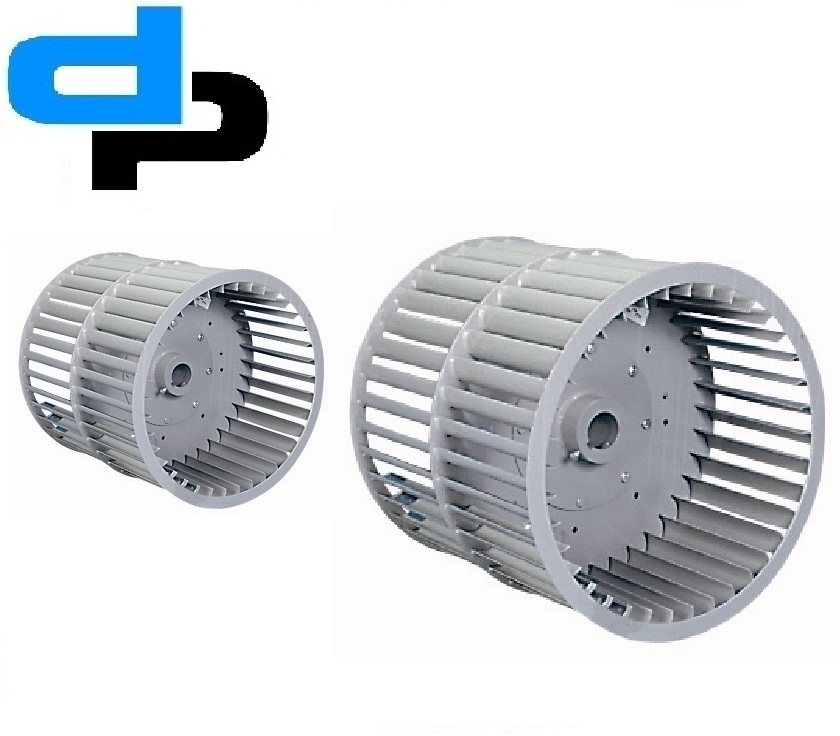

DIDW Centrifugal Fan 151 MM X 228 MM

DIDW Centrifugal Fan 151 MM X 228 MM Specification

- Power

- 0.75 kW

- Motor Power

- 1 HP

- Max Pressure

- 350 Pa

- Flow Rate

- 1000 m3/h

- Life Span

- 10 Years

- Output Power

- 0.75 kW

- Pressure Range

- 200-350 Pa

- Product Type

- Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 1000 CFM

- Pressure

- 350 Pa

- Application

- Industrial Ventilation, HVAC, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <=75 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- 7.5 kg

- Dimension (L*W*H)

- 151 mm x 228 mm

- Color

- Grey

DIDW Centrifugal Fan 151 MM X 228 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Sample Available

- Yes

- Main Domestic Market

- Himachal Pradesh, Manipur, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Uttar Pradesh, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Dadra and Nagar Haveli, Lakshadweep, All India, Central India, Odisha, West India, Chhattisgarh

About DIDW Centrifugal Fan 151 MM X 228 MM

DIDW Centrifugal Fan 151 MM X 228 MM

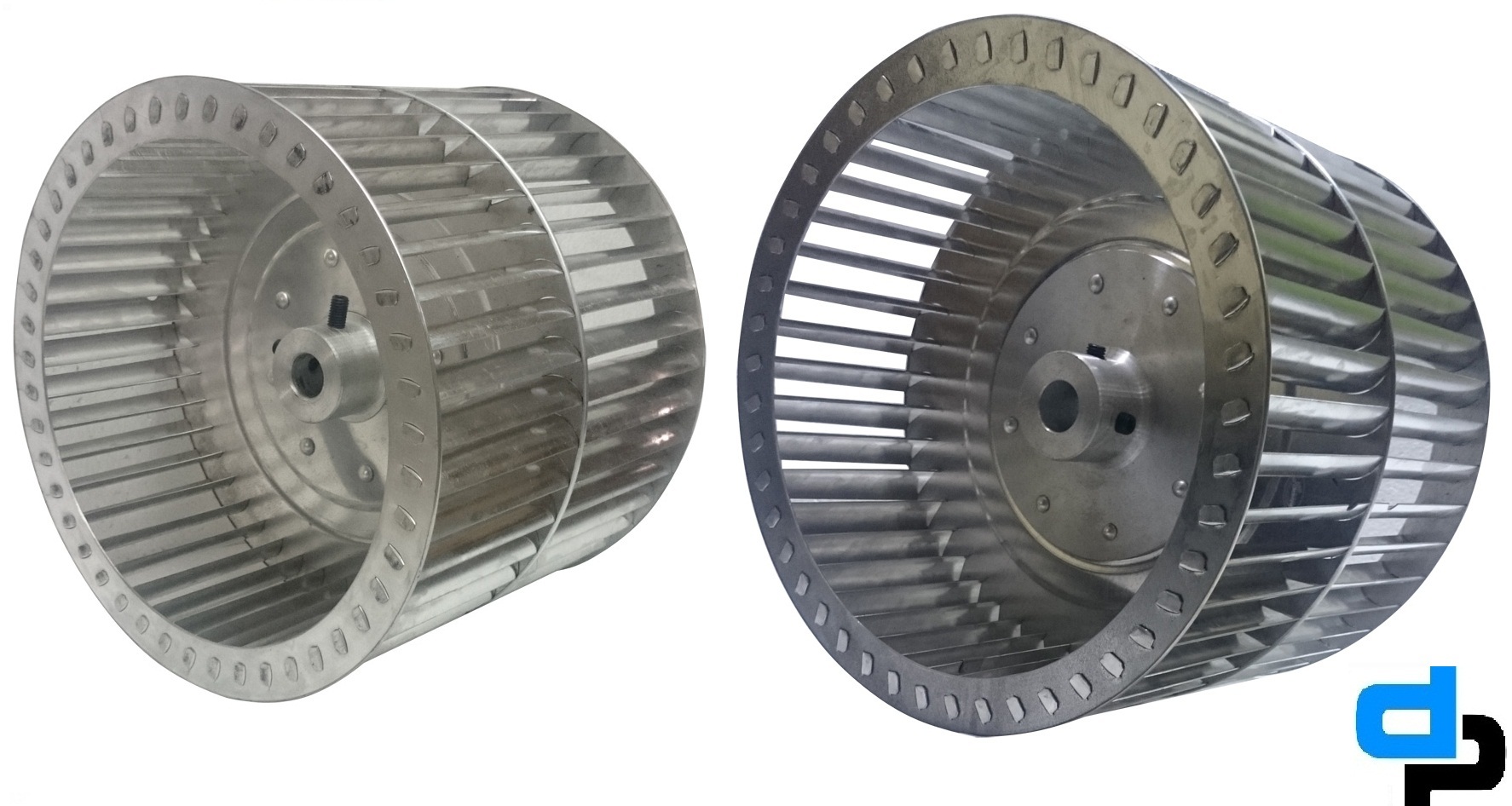

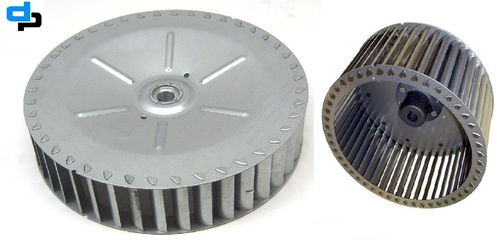

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 11 | DP 6 90 | 151 X 228 X 122 | 6 X 9 | 12.70 (1/2'') & 15 MM | AL. / GI. |

Designed for Heavy-Duty Industrial Use

Engineered to meet the rigorous demands of industrial ventilation and HVAC settings, this centrifugal fan excels in environments where durability and performance are paramount. With its totally enclosed construction, robust mild steel body, and sealed ball bearings, the fan ensures uninterrupted operation even under challenging conditions. Its versatility makes it ideal for manufacturing plants, large-scale air handling, and high-capacity ventilation systems.

Exceptional Performance and Versatility

Delivering a maximum flow rate of 1000 m3/h and a peak pressure of 350 Pa, this DIDW centrifugal fan is equipped to handle substantial ventilation needs. The dual rotation capability (clockwise and counterclockwise) enables flexible installation in diverse systems. Advanced insulation (Class F) and efficient power consumption (0.75 kW) further underscore its suitability for sustained, reliable operation in varied settings.

FAQs of DIDW Centrifugal Fan 151 MM X 228 MM:

Q: How does the double inlet double width (DIDW) design improve the efficiency of this centrifugal fan?

A: The DIDW configuration allows for higher airflow rates by drawing air into the impeller from both sides. This design minimizes turbulence, ensures uniform air distribution, and enhances overall efficiency, making it ideal for industrial ventilation and HVAC applications.Q: What maintenance is required to ensure optimal performance and a long lifespan?

A: Routine maintenance involves checking the sealed ball bearings, ensuring the fan and motor remain free from dust and debris, and inspecting electrical connections. Regular attention helps maximize its 10-year lifespan while maintaining energy efficiency and low noise output.Q: Where can this centrifugal fan be installed?

A: This fan is suitable for use in industrial environments, HVAC systems, air handling units, factories, and large commercial spaces. Its base-mounted design and flexible rotation options allow for straightforward integration into new and existing ventilation setups.Q: When should the centrifugal fan be used within an HVAC system?

A: It is best utilized when a high volume of air movement is needed, such as in centralized air handling units, supply/return air systems, or industrial ventilation setups that require consistent and efficient airflow for temperature and air quality control.Q: What are the key benefits of using this model in industrial ventilation?

A: Key benefits include reliable high-capacity airflow, sturdy construction for long-term use, low maintenance due to sealed bearings, moderate noise levels (75 dB), energy-efficient performance, and adaptability to a broad range of operating temperatures (-10C to 60C).Q: How do the forward curved blades affect the airflow and noise levels?

A: Forward-curved blades generate smoother airflow with less turbulence, resulting in efficient energy use and relatively low noise levels. This ensures a quieter environment even in high-demand applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 230 MM X 178 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 100350 Pa

Frequency (MHz) : 50 Hz

Color : Silver / Grey

Power Source : Other, Electric

DIDW Centrifugal Fan 151 MM X 152 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 150170 Pa

Frequency (MHz) : 50 Hz

Color : Silver

Power Source : Other, Electric

DIDW Centrifugal Fan 280 MM X 150 MM

Price 3000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 200400 Pa

Frequency (MHz) : 50 Hz

Color : Blue

Power Source : Other, Electric

DIDW Centrifugal Fan 280 MM X 305 MM

Price 4000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 10 50 mm WG

Frequency (MHz) : 50 Hz

Color : Blue

Power Source : Other, Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS