Chillcel Cellulose Pad

Chillcel Cellulose Pad Specification

- Application

- Evaporative cooling systems, greenhouse humidification, poultry, industrial cooling

- Material

- Cellulose fibre, impregnated and specially treated

- Refrigerating Capacity

- Depends on application and system design

- Air Flow

- High airflow design for efficient cooling

- Condition

- New

- Type

- Evaporative Cooling Pad

- Dimension (L*W*H)

- Varies as per requirement; commonly available sizes include 600mm x 300mm x 150mm

- Cooling Type

- Evaporative

- Nozzle Material

- Compatible plastic/metal for water distribution

- Water Flowing Rate

- Optimized for uniform moisture distribution

- Water Pump Motor

- Selected as per system capacity

- Noise Control

- Low noise operation

About Chillcel Cellulose Pad

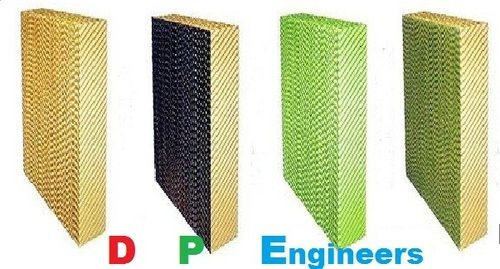

Chillcel Cellulose Padwe manufacture our own high-density, cross-corrugated Chillcel Cellulose Pad . They're matched to your cooler for maximum effect. Our ChillCel pads provide the highest cooling efficiency of any Chillcel Cellulose Pad .

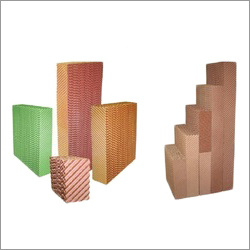

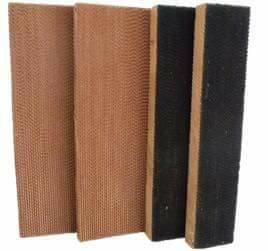

On average Chillcel Cellulose Pad are around 4"-8" thick, which we believe provides optimum efficiency. Other brands may claim that thicker pads provide better cooling. The facts are that only a certain amount of water can evaporate into the air. Thicker pads cannot make any more water evaporate - unless the pads themselves are quite inefficient to begin with.

Thicker pads may require greater power to draw the air through, a larger pump to move the volume of water required and provide an ideal environment for efficiency sapping salt and mineral buildup. In other words, they probably cost more to buy, more to run and need to be replaced more often.

Advanced Structure for Superior Cooling

Chillcel pads utilize a proprietary 45/45 cross flute pattern designed to optimize both airflow and water distribution, resulting in efficient evaporative cooling. This unique structure, combined with high-quality cellulose fibres, supports high refrigerating capacity depending on system design and application, making them suitable for both industrial and agricultural uses.

Long-Lasting Performance and Hygiene

With anti-bacterial edge protection and flame-retardant options, Chillcel pads offer a safe and hygienic solution for cooling environments. The treated edges inhibit microbial buildup, while the flame-retardant cellulose enhances workplace safety. Expect a durable pad life span of 35 years, reducing frequent replacement needs and maintenance costs.

Simple Installation and Versatile Applications

Installation is streamlined due to compatibility with modular frames and standardized dimensions. Chillcel pads can be easily integrated into new or existing cooling systems for greenhouses, poultry, or industrial spaces. Packed in plastic-wrapped bundles, these pads ensure effective moisture control and cooling with optimized water and air flow rates.

FAQs of Chillcel Cellulose Pad :

Q: How do Chillcel Cellulose Pads enhance evaporative cooling efficiency?

A: Chillcel pads feature a 45/45 cross flute structure that maximizes water absorption and airflow. This design promotes uniform moisture distribution, ensuring highly efficient heat exchange and effective cooling in various applications, such as greenhouses and industrial environments.Q: What options are available for pad dimensions and thickness?

A: Chillcel pads are commonly available in widths between 300 mm and 600 mm, heights from 300 mm to 1800 mm, and the standard thickness is 150 mm. Custom sizes and thicknesses can be requested to suit specific installation requirements or system designs.Q: When should I replace the Chillcel Cellulose Pads?

A: Typically, Chillcel pads last between 3 to 5 years, depending on intensity of use and environmental conditions. Replacement is recommended when water absorption drops, airflow is reduced, or visible wear and tear occurs, ensuring your cooling systems optimal performance.Q: Where can Chillcel pads be installed for effective usage?

A: Chillcel pads are suitable for a range of applications, including evaporative cooling systems in greenhouses, poultry houses, and industrial cooling setups. Their modular compatibility allows easy installation in new or retrofit projects across these sectors.Q: What are the maintenance requirements for Chillcel Cellulose Pads?

A: Maintenance is minimalregular rinsing and periodic inspection help prevent dust accumulation and ensure effective water flow. The anti-bacterial edge treatment further reduces microbial buildup, making the pads easy to clean and maintain over their lifespan.Q: How does the flame retardant feature benefit my cooling system?

A: The flame-retardant version of Chillcel pads improves workplace safety by reducing fire risk, particularly in high-temperature or industrial environments. This option may be required to meet specific regulatory or safety standards in certain installations.Q: Are Chillcel pads compatible with different water distribution systems?

A: Yes, Chillcel pads are designed to work with plastic or metal nozzles according to system specifications. Water pump motors can be selected based on system capacity, ensuring the pads receive uniform moisture for consistent cooling.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS