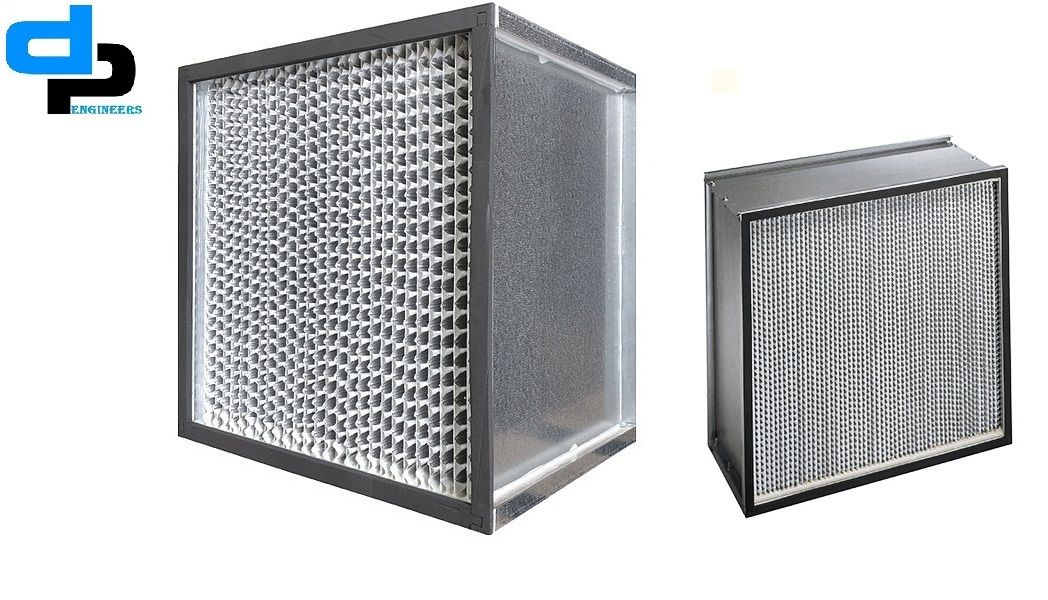

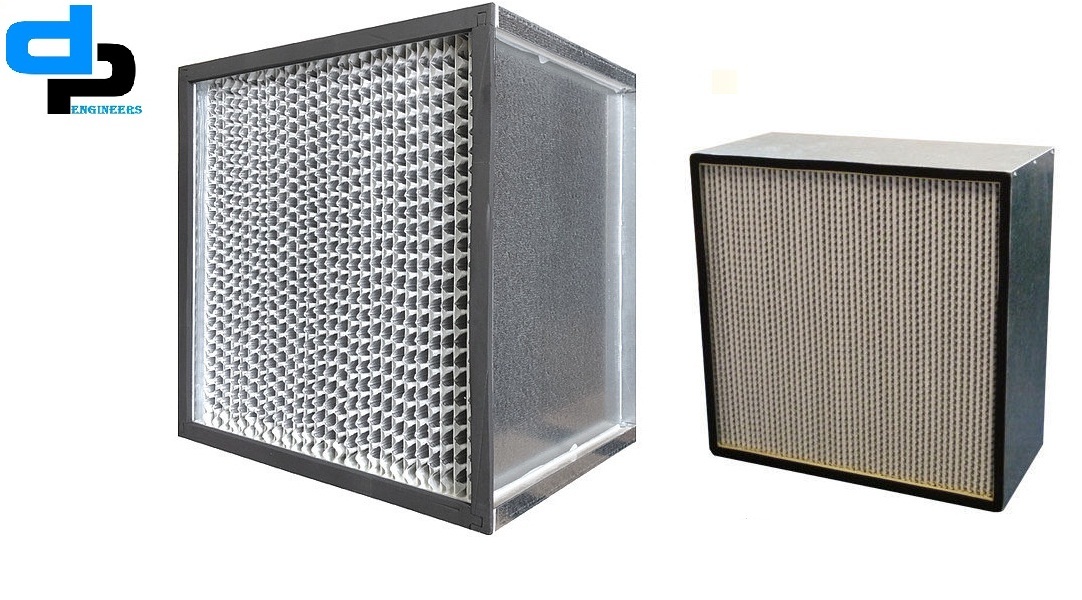

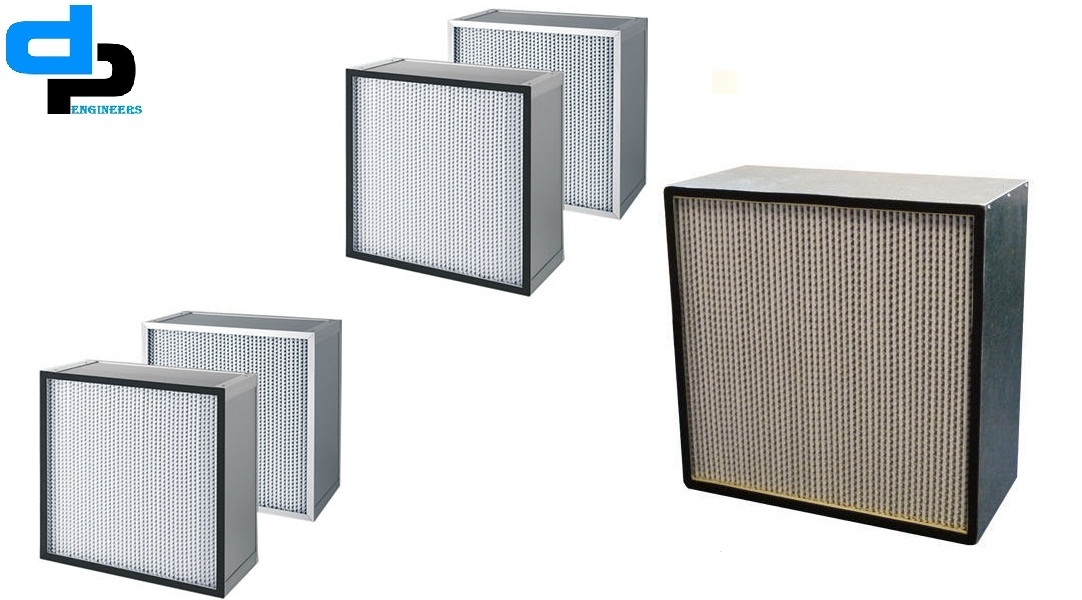

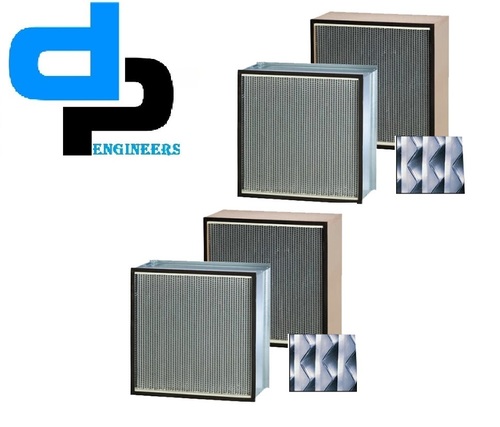

Absolute Compact Filters

Price 4500 INR/ Piece

Absolute Compact Filters Specification

- Flow Rate

- Up to 3600 m/h (varies by model)

- Cleaning Method

- Non-washable, Disposable

- Filter Type

- Panel Compact Filter

- Connecting Type

- Flange / Gasket

- Efficiency (%)

- Up to 99.99%

- Pressure

- Max. 450 Pa

- Temperature Range

- -20C to +80C

- Capacity

- Designed for high dust loading

- Filtration Grade

- HEPA/ULPA (as per design)

- Media Type

- Glass Fiber / Synthetic

- Condition

- New

- Material

- Glass Fiber/Pleated Synthetic Media

- Mesh

- Micro-fine (absolute rating)

- Diameter

- Standard: 150 mm, Customizable

- Construction

- Deep-pleat design with robust frame

- Medium Filter

- Air & Liquid

- Weight

- Lightweight (varies with configuration)

- Shape

- Rectangular or custom

- Feature

- High particulate holding capacity, Compact design for space saving, Suitable for critical air & liquid filtration

Absolute Compact Filters Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Delhi

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 10-12 Days

- Packaging Details

- Websites : www.dpengineers.in www.dpengineer.in www.dpengineers.co.in www.dpengineer.co.in www.dpengineersindia.com www.dpengineerindia.com www.dpengineersindia.in www.dpengineers.info www.dpengineer.info www.dp-engineers.com www.dpengineerindia.in www.dpengineersindia.net www.dpengineersdelhi.co.in www.dpengineersdelhi.com www.dpengineersdelhi.net

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, Nagaland, South India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Kerala, Central India, Odisha, Chhattisgarh, All India

About Absolute Compact Filters

Absolute compact filters are designed for use in hvac industrial applications requiring cleaner air but where hepa filtered air is not required. These filters are also known as efficiency particulate air filter (epa). The micro fine glass fibrer paper with backing media folded to form deep folds and corrugated aluminium foil separators used to separate the pleats in the filter pack.

Features:

- maximum utilization of the media

- longer service life and high dust holding capacity

- suitable for variable air flow

- robust design

- specifications:

- media : micro fine glass fibrer (imported) with backing media

- frame : aluminium,galvanised iron, stainless steel

- Type : box/ flange

- filter class en1822 : e10-e12

- efficiency (%) : 95

Superior Filtration Efficiency

These compact filters deliver HEPA/ULPA grade filtration with up to 99.99% efficiency, making them well-suited for critical environments where air quality is paramount. The micro-fine media and deep-pleat construction provide robust particulate retention while minimizing airflow resistance.

Robust and Versatile Construction

Available in frames of galvanized steel, aluminum, or plastic, these filters are engineered for both vertical and horizontal installations. Seamless polyurethane gaskets ensure leak-proof fitting, and customizable shapes and diameters integrate seamlessly into any system. Their lightweight yet sturdy build allows easy handling and installation.

Engineered for Demanding Environments

Complying with EN 1822 and ISO 16890, these filters excel in challenging conditions ranging from -20C to +80C and withstand pressures up to 450 Pa. Their high dust retention capacity and disposable design simplify maintenance, while their space-saving profile makes them ideal for facilities where every centimeter matters.

FAQs of Absolute Compact Filters:

Q: How are Absolute Compact Filters installed, and what kind of systems do they fit into?

A: These filters are designed for easy installation in both vertical and horizontal positions, using flange or gasket connections. They fit HVAC systems, cleanrooms, laboratories, pharmaceutical production, and food processing lines, ensuring compatibility with standard and custom panel sizes.Q: What is the typical replacement frequency for these filters?

A: Filter replacement depends on the application and environmental conditions, commonly ranging from every 6 to 12 months. High particulate environments may require more frequent changes to maintain optimal filtration efficiency.Q: Where are Absolute Compact Filters most commonly used?

A: They are ideal for critical environments such as cleanrooms, pharmaceutical manufacturing, food processing facilities, laboratories, and advanced HVAC installations, where high air or liquid purity is essential.Q: What makes these filters particularly beneficial for sensitive applications?

A: Their HEPA/ULPA filtration performance, high dust holding capacity, and robust leak-proof design ensure reliable containment of particles, supporting stringent cleanliness standards required in sensitive industries.Q: What process ensures a leak-proof fit for these filters?

A: A seamless polyurethane gasket is used for each filter, guaranteeing a secure, leak-proof seal between the filter and its housing, preventing bypass and maintaining integrity of the filtered air or liquid.Q: Can the filter diameter or shape be customized for unique installation requirements?

A: Yes, along with standard 150 mm diameter, the filters can be custom-engineered in various shapes or sizes to accommodate specific system or process needs.Q: Are Absolute Compact Filters reusable or disposable, and how is cleaning handled?

A: These filters are non-washable and are designed to be disposable after their service life, ensuring simple, hygienic replacement without risk of contaminant release during cleaning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HEPA Filters Category

Aluminium Anodized HEPA filters in Roorkee

Price 4850 INR / Piece

Minimum Order Quantity : 10 Pieces

Filtration Grade : Hepa Filter

Construction : Box Filter

Medium Filter : Fiber Glass

Usage : pharmaceutical,Hotel,Malls,Hospital, OT

Mini Pleat HEPA FILTER by Chinmaya Nagar Chennai

Price 7800 INR / Piece

Minimum Order Quantity : 24 Pieces

Filtration Grade : Hepa Filter

Construction : Box Filter

Medium Filter : Fiber Glass

Usage : pharmaceutical,Hotel,Malls,Hospital,OT,POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE,Pharmaceutical Manufacture,Food And Beverages Industry,Pulp And Paper Industry,Textile Industry

Deep Pleat HEPA Filter

Price 5000 INR / Piece

Minimum Order Quantity : 10 Pieces

Filtration Grade : Hepa Filter

Construction : Box Filter

Medium Filter : Fiber Glass

Usage : HEPA filter Used in biomedical purpose, vacuum cleaners, nuclear industry, aerospace, nuclear power, pharmaceutical processing, health care, hospitals, nuclear fuels, and electronic micro circuitry (computer chips).

High Efficiency Particulate Air Filter

Price 5000 INR / Piece

Minimum Order Quantity : 10 Pieces

Filtration Grade : Hepa Filter

Construction : Box Filter

Medium Filter : Fiber Glass

Usage : Clean rooms for micro component electronic manufacture & assembly. Pharmaceutical processing. Aerospace engineeing. Genetic & biological researh. Biohazard atmosphere. Laminar flow workstations. Bio safe hood { biological safety cabinets}. Hospital operating theaters & intensive care unit. Atomic research. Pre filter stage to ulpa systems.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS