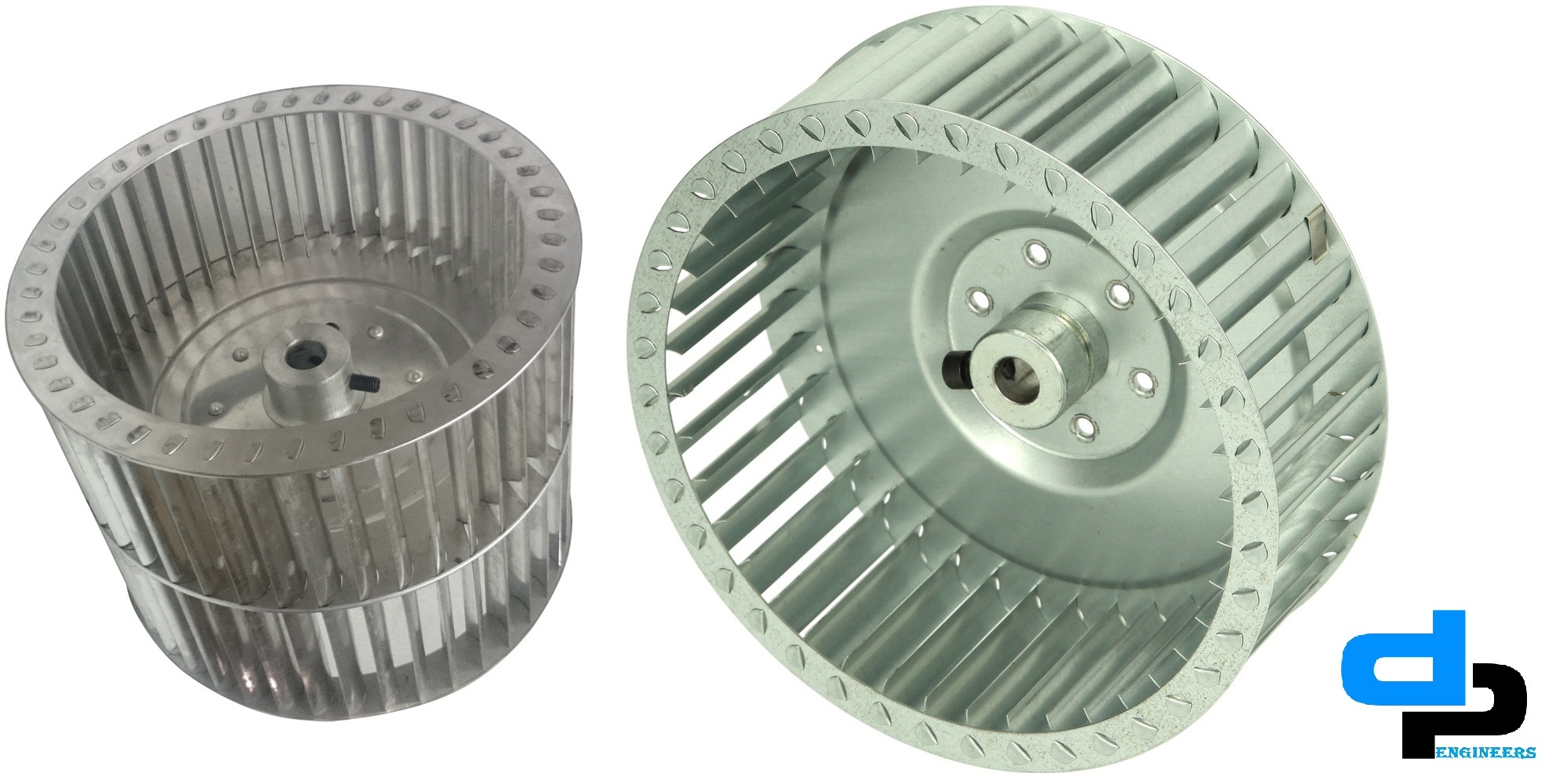

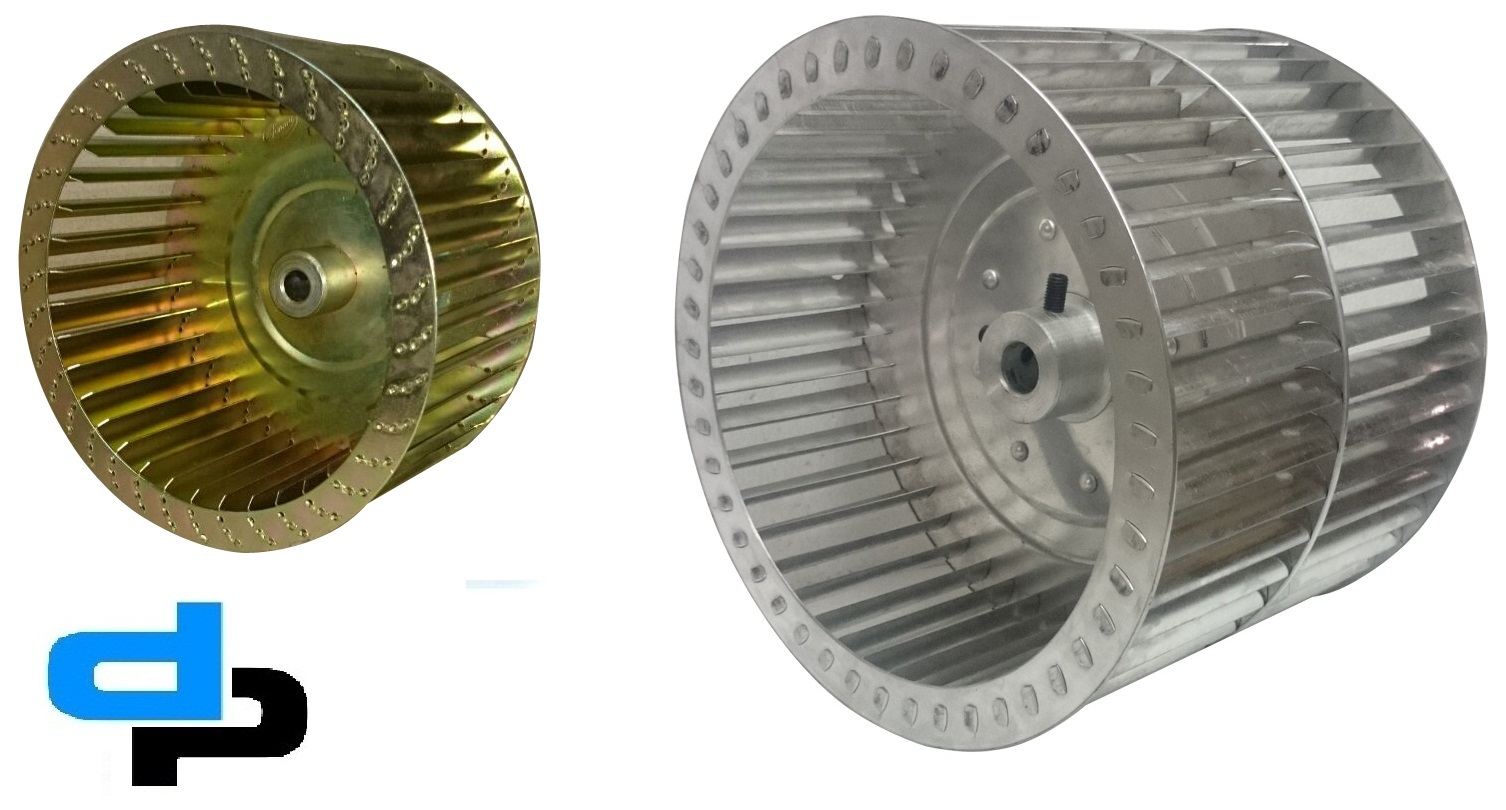

SISW Centrifugal Blower 455 MM X 200 MM

SISW Centrifugal Blower 455 MM X 200 MM Specification

- Output Power

- 2.2 kW

- Motor Power

- 3 HP

- Max Pressure

- 120 mmWC

- Pressure Range

- 50-120 mmWC

- Power

- 2.2 kW

- Life Span

- 10-15 years under normal use

- Flow Rate

- 2500-4000 m/h

- Product Type

- Single Inlet Single Width (SISW) Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 2500-4000 m/h

- Pressure

- 50-120 mmWC

- Application

- Industrial Ventilation, Air Handling, HVAC, Dust Collection

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 415 V AC

- Weight

- Approx. 60 kg

- Dimension (L*W*H)

- Approx. 700 mm x 500 mm x 600 mm

- Color

- Blue/Grey

SISW Centrifugal Blower 455 MM X 200 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Jammu and Kashmir, Tripura, Manipur, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, South India, East India, Assam, Arunachal Pradesh, Bihar, Goa, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Uttarakhand, Daman and Diu, All India, Lakshadweep, Uttar Pradesh, Gujarat, Delhi, Haryana, Karnataka, North India, Punjab, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh

About SISW Centrifugal Blower 455 MM X 200 MM

SISW Centrifugal Blower 455 MM X 200 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 34 | ETIP 18 80 | 455 X 200 X 365 | 18 X 8 | 35 MM & 1.5 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Exceptional Performance and Versatility

The SISW Centrifugal Blower is constructed for high-demand industrial situations. Its dynamically balanced impeller guarantees stability, with direct or belt drive options for adaptability. Compatibility with variable frequency drives provides precise speed adjustments, catering to varied ventilation and air handling requirements across factories, warehouses, and HVAC systems.

Durable Construction for Longevity

Built with welded, powder-coated mild steel housing, the blower withstands industrial environments while offering prolonged service. The IP55-protected motor and heavy-duty ball bearings allow operation in challenging settings, while Class F insulation ensures motor safety under continuous use.

Efficient Airflow and Low Noise Operation

Delivering an airflow rate up to 4000 m/h within a pressure range of 50120 mmWC, this blower maintains noise levels below 80 dB, supporting quieter industrial operations. Its horizontal discharge orientation optimizes airflow directionality for efficient space utilization and process performance.

FAQs of SISW Centrifugal Blower 455 MM X 200 MM:

Q: How is the SISW Centrifugal Blower typically installed?

A: This blower features a base-mounted design, making it straightforward to secure onto flat industrial surfaces. Mounting hardware and recommendations for anchoring are provided to ensure stability and safe operation.Q: What are the main benefits of a backward curved impeller in this blower?

A: A backward curved impeller minimizes the risk of clogging and delivers higher efficiency with stable airflow. It reduces energy consumption and ensures consistent performance, making it suitable for dust-laden and high-demand environments.Q: When should variable frequency drive (VFD) speed control be utilized with this blower?

A: Variable frequency drive compatibility is beneficial when precise airflow adjustment is required, such as in variable-load ventilation systems or energy-saving operations. VFDs allow tailored performance to match changing application needs.Q: Where can the SISW Centrifugal Blower be employed most effectively?

A: This blower excels in industrial settings, including factories, warehouse ventilation, HVAC systems, air handling units, and dust collection processes. Its robust design meets the demands of diverse mechanical environments.Q: What is the recommended process for routine maintenance of the blower?

A: Regular maintenance includes checking and cleaning the impeller to prevent debris buildup, lubricating the heavy-duty ball bearings, inspecting the motor, and ensuring the enclosure stays free from dust and moisture. Periodic checks help ensure longevity and optimal operation.Q: How does the enclosure protection (IP55) benefit the motor?

A: IP55 protection shields the motor from dust ingress and water jets, ensuring reliable functioning in dusty or damp industrial environments. This enhances component lifespan and minimizes the risk of malfunction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 250 MM X 125 MM

Price 1800 INR

Minimum Order Quantity : 5 Pieces

Life Span : 810 Years

Weight : 13 Kg

Motor Speed : 2880 RPM

Product Type : Others, SISW (Single Inlet Single Width) Centrifugal Blower

ISW Centrifugal Blower 100 MM X 63 MM

Price 550 INR

Minimum Order Quantity : 5 Pieces

Life Span : 810 Years

Weight : Approx. 57 kg

Motor Speed : 2800 RPM

Product Type : Centrifugal Blower

SISW Centrifugal Blower 180 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Life Span : Up to 8 years (under standard operating conditions)

Weight : 8 kg

Motor Speed : 2800 RPM

Product Type : Others, Single Inlet Single Width (SISW) Centrifugal Blower

SISW Centrifugal Blower 250 MM X 75 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Life Span : 15 Years (approx)

Weight : Approx 9 Kg

Motor Speed : 2800 RPM

Product Type : Others, SISW Centrifugal Blower

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS