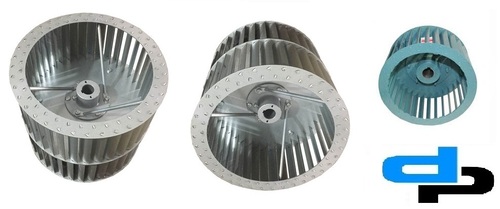

SISW Centrifugal Blower 250 MM X 75 MM

SISW Centrifugal Blower 250 MM X 75 MM Specification

- Flow Rate

- 600 CFM

- Power

- 1 HP

- Output Power

- 0.75 kW

- Pressure Range

- 50-100 mm WC

- Motor Power

- 0.75 kW

- Max Pressure

- 100 mm WC

- Life Span

- 15 Years (approx)

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 600 CFM

- Pressure

- Medium Pressure

- Application

- Industrial ventilation, Air exhaust, Fume extraction, Cooling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Low

- Power Source

- Electric

- Voltage

- 220 - 240 V

- Weight

- Approx 9 Kg

- Dimension (L*W*H)

- 250 mm x 75 mm

- Color

- Blue

- Number of Phases

- Single Phase / Three Phase

- Drive Type

- Direct Drive

- Bearing Type

- Ball Bearing

- Insulation Class

- Class F

- Enclosure

- IP55

- Blower Orientation

- SISW (Single Inlet Single Width)

- Mounting Type

- Base Mounted

- Duct Connection Size

- 250 mm

- Impeller Type

- Backward Curved

SISW Centrifugal Blower 250 MM X 75 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Manipur, Nagaland, South India, North India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Andhra Pradesh, Central India, Chhattisgarh, All India

About SISW Centrifugal Blower 250 MM X 75 MM

SISW Centrifugal Blower 250 MM X 75 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 19 | DP 10 30 | 250 X 75 X 210 | 10 X 3 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Advanced Design for Industrial Ventilation

Built with a backward curved impeller for enhanced efficiency, this SISW centrifugal blower is ideal for handling air exhaust, ventilation, and fume extraction tasks in industrial environments. Its base mounted and direct drive configuration ensures easy installation and stable operation, supporting continuous usage under demanding conditions.

High Performance & Reliability

Operating at motor speeds of 2800 RPM and offering a flow rate of 600 CFM, the blower combines low noise with consistent medium pressure output. The IP55 enclosure, Class F insulation, and ball bearing design reassure safety and longevity, while mild steel construction delivers long-term resistance against wear and corrosion.

FAQs of SISW Centrifugal Blower 250 MM X 75 MM:

Q: How is the SISW Centrifugal Blower installed in an industrial setting?

A: This blower is base mounted, allowing it to be securely bolted onto flat surfaces or platforms. The duct connection size is 250 mm, enabling straightforward integration with existing ventilation or exhaust ducts, commonly found in factories and workshops.Q: What applications are suitable for the SISW Centrifugal Blower?

A: It is designed for industrial ventilation, air exhaust, fume extraction, and cooling. The blowers medium pressure capacity and low noise operation make it effective in manufacturing plants, chemical facilities, and commercial spaces requiring air movement or contaminant removal.Q: Where can this centrifugal blower be used?

A: The blower is ideal for installation in industrial environments throughout India, such as production lines, HVAC systems, laboratories, and warehouses needing efficient air handling. It is supplied by exporters, manufacturers, and traders for various sectors.Q: What is the maintenance process required for the blower?

A: Routine maintenance involves inspecting ball bearings, cleaning the impeller, and ensuring the motor functions within the specified voltage (220240 V) and frequency (50 Hz). Periodic checks assist in prolonging operational life, estimated at around 15 years.Q: What are the benefits of using a blower with Class F insulation?

A: Class F insulation enhances the motors resistance to heat and electrical stress, supporting consistent performance during prolonged or high-load operation. This increases reliability and minimizes the risk of insulation failure over the products lifespan.Q: How does the direct drive mechanism improve blower efficiency?

A: Direct drive reduces energy losses by eliminating the need for belts or pulleys, resulting in enhanced mechanical efficiency, lower maintenance, and improved output consistency. This ensures sustained airflow and pressure without excess wear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 150 MM X 75 MM

Price 800 INR

Minimum Order Quantity : 5 Pieces

Power : 0.5 HP

Material : other , Mild Steel

Color : Blue

Output Power : 0.37 kW

SISW Centrifugal Blower 610 MM X 250 MM

Price 16000 INR

Minimum Order Quantity : 5 Pieces

Power : 5 HP

Material : other , Mild Steel

Color : Blue

Output Power : 3.7 kW

SISW Centrifugal Blower 300 MM X 125 MM

Price 4500 INR

Minimum Order Quantity : 5 Pieces

Power : 0.75 kW

Material : other , Mild Steel

Color : Metal Grey

Output Power : 0.75 kW

SISW Centrifugal Blower 165 MM X 75 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Power : 0.37 KW

Material : other , Mild Steel

Color : Silver Grey

Output Power : 0.5 HP

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS