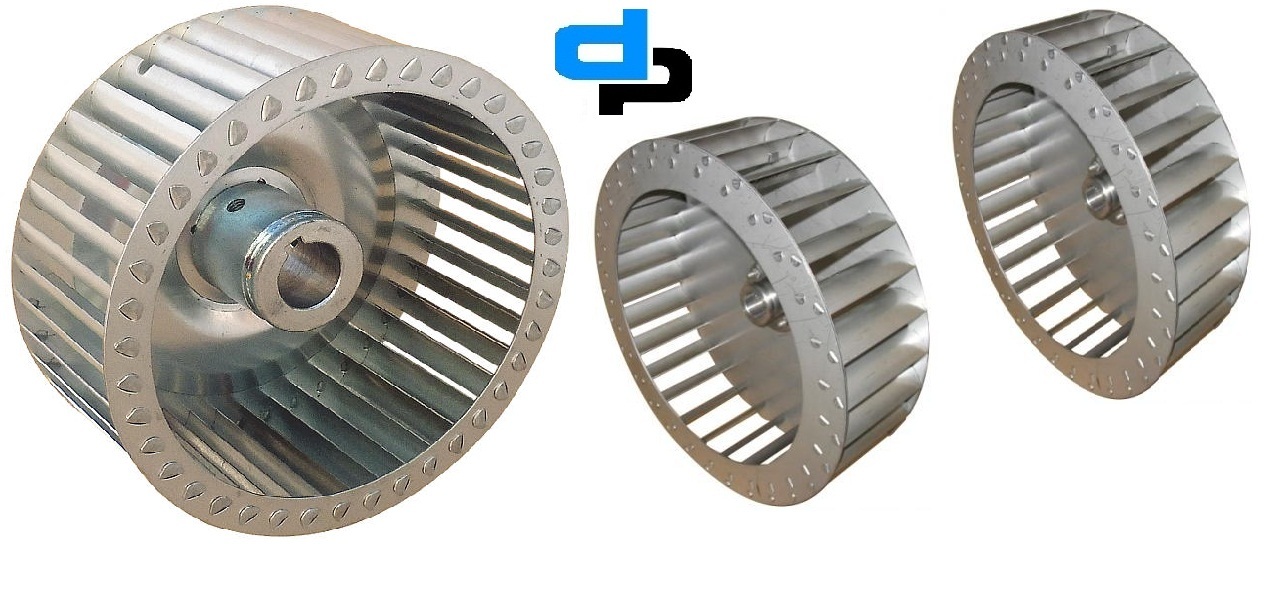

SISW Centrifugal Blower 230 MM X 100 MM

SISW Centrifugal Blower 230 MM X 100 MM Specification

- Max Pressure

- 50 mm WG

- Motor Power

- 0.5 HP

- Output Power

- 0.37 kW

- Pressure Range

- 30-50 mm WG

- Flow Rate

- 400 CFM

- Power

- 0.37 kW

- Life Span

- 5-7 Years (approx.)

- Product Type

- Single Inlet Single Width (SISW) Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 400 CFM

- Pressure

- 45 mm WG

- Application

- Industrial ventilation, Air cooling, HVAC, Exhaust systems

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <70 dB

- Power Source

- Electric

- Voltage

- 230 V AC

- Weight

- 7.5 kg

- Dimension (L*W*H)

- 230 mm x 100 mm x 180 mm (approx.)

- Color

- Metallic Grey

SISW Centrifugal Blower 230 MM X 100 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Manipur, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Haryana, Gujarat, North India, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

About SISW Centrifugal Blower 230 MM X 100 MM

SISW Centrifugal Blower 230 MM X 100 MM

SISW CENTRIFUGAL BLOWER

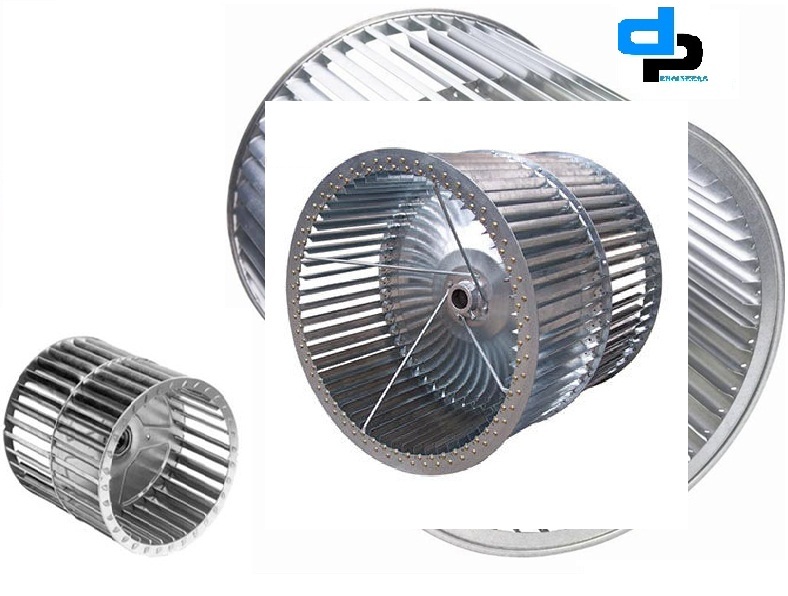

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 17 | DP 9 40 | 230 X 100 X 190 | 9 X 4 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

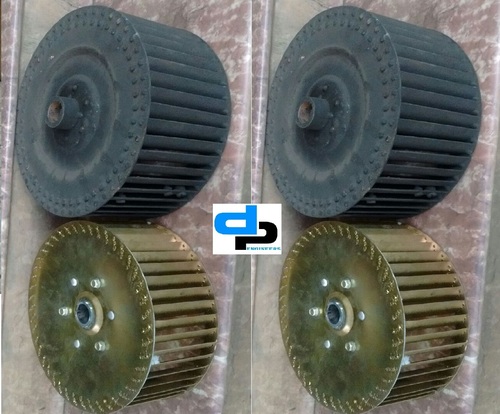

Superior Performance in Challenging Environments

This centrifugal blowers TEFC motor and sealed ball bearings allow it to function optimally in dusty or moisture-laden environments, minimizing maintenance needs. The forward curved impeller and horizontal airflow design ensure efficient movement of air, making it suitable for demanding industrial ventilation and HVAC applications.

Reliable and Safe Construction

Manufactured with mild steel and finished in powder-coated metallic grey, the blower resists corrosion and physical damage. The Class F insulation enhances motor safety, and the robust base-mounted structure ensures stability during continuous operation, supporting industrial reliability.

Energy Efficient and Quiet Operation

With a power output of 0.37 kW (0.5 HP) and a noise level lower than 70 dB, this blower meets both energy-saving and acoustical requirements. It is ideal for settings where continuous air movement is needed without excess power consumption or disruptive noise.

FAQs of SISW Centrifugal Blower 230 MM X 100 MM:

Q: How do I install the SISW Centrifugal Blower in my ventilation system?

A: The blower features a base-mounted design, allowing secure installation on flat surfaces. Ensure proper alignment with ductwork for horizontal airflow, and follow the provided mounting instructions to optimize performance and reduce vibration.Q: What applications is this centrifugal blower suitable for?

A: This model is designed for industrial ventilation, air cooling, HVAC systems, and exhaust systems. Its robust construction and reliable airflow make it ideal for demanding environments where consistent air movement is essential.Q: When should sealed ball bearings be serviced or replaced in this blower?

A: The blowers sealed ball bearings are maintenance-free under normal operating conditions. For maximum lifespan, periodic inspection is recommended, but replacement is typically not required unless signs of wear or noise arise after several years of service.Q: Where can this blower be safely operated given its enclosure and insulation?

A: Thanks to its TEFC motor enclosure and Class F insulation, the blower can be used in environments exposed to dust, humidity, or fluctuating temperatures ranging from -10C to 60C, ensuring reliable performance and electrical safety.Q: What are the noise and energy benefits of using this blower?

A: Operating at less than 70 dB, the blower minimizes noise disturbances, making it suitable for continuous use in noise-sensitive areas. Its efficient 0.37 kW direct drive motor reduces energy consumption, contributing to lower operating costs.Q: How does the powder-coated mild steel finish benefit the blowers longevity?

A: The powder coating provides a tough, corrosion-resistant surface that protects the mild steel housing from environmental damage, helping extend the blowers service life to 5-7 years in industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 280 MM X 100 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Max Pressure : 80 mm WC

Motor Power : 1.5 HP / 2 HP

Capacity : 9001200 CFM

Color : Silver/Grey

SISW Centrifugal Blower 250 MM X 75 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Max Pressure : 100 mm WC

Motor Power : 0.75 kW

Capacity : 600 CFM

Color : Blue

SISW Centrifugal Blower 300 MM X 150 MM

Price 5000 INR

Minimum Order Quantity : 4 Pieces

Max Pressure : 150 mmWG

Motor Power : 2 HP

Capacity : Up to 2200 CFM

Color : Blue / Grey

SISW Centrifugal Blower 380 MM X 150 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Max Pressure : 80 mm WC

Motor Power : 1.5 kW

Capacity : Up to 800 CFM

Color : Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS