SISW Centrifugal Blower 250 MM X 125 MM

SISW Centrifugal Blower 250 MM X 125 MM Specification

- Flow Rate

- 500-900 m3/h

- Motor Power

- 0.37-1.1 kW

- Life Span

- 8-10 Years

- Output Power

- 0.37 - 1.1 kW

- Max Pressure

- 80 mm WC

- Pressure Range

- 20-80 mm WC

- Power

- 0.5-1.5 HP

- Product Type

- SISW (Single Inlet Single Width) Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 500-900 CFM

- Pressure

- Up to 80 mm WC

- Application

- Industrial Air Ventilation, Exhaust, Cooling, HVAC

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2880 RPM

- Noise Level

- Less than 80 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- 13 Kg

- Dimension (L*W*H)

- Approx. 250mm x 125mm x 300mm

- Color

- Blue/Grey

SISW Centrifugal Blower 250 MM X 125 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Chhattisgarh, Kerala, Nagaland, South India, East India, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Gujarat, North India, Andhra Pradesh, Central India, Odisha, West India, All India

About SISW Centrifugal Blower 250 MM X 125 MM

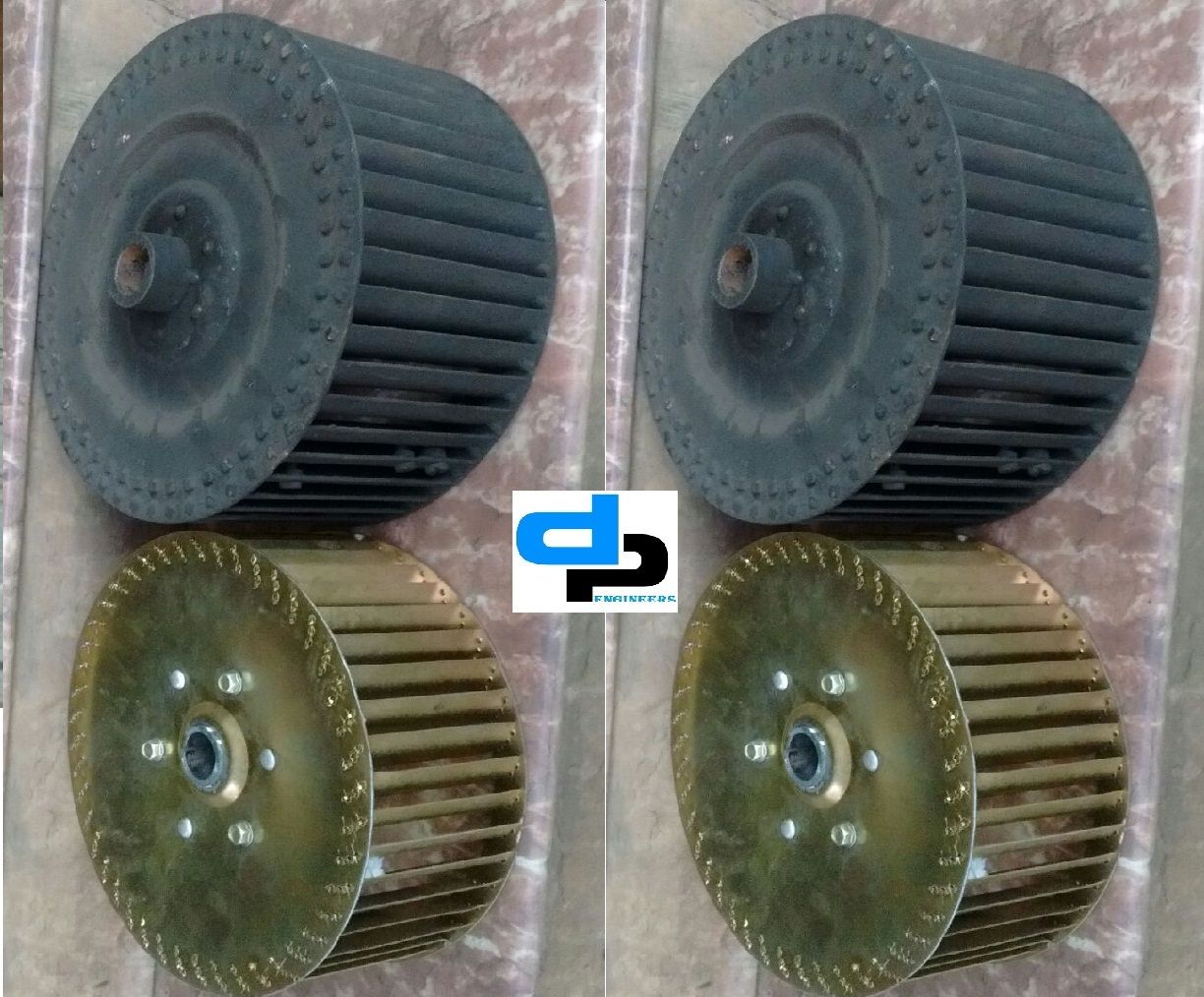

SISW Centrifugal Blower 250 MM X 125 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 21 | DP 10 50 | 250 X 125 X 210 | 10 X 5 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Efficient Ventilation and Exhaust

The SISW Centrifugal Blower is engineered to deliver powerful airflow for industrial settings. With its high-capacity fan wheel and reliable motor, it maintains optimal ventilation and exhaust, ensuring a safer and more comfortable work environment by removing contaminants and excess heat efficiently.

Durable and Versatile Construction

Designed with mild steel and available in powder-coated finishes, the blower withstands rigorous use in diverse conditions. Offering flexibility with direct or belt drive options and a sturdy base-mounted design, it suits multiple installation requirements in factories, warehouses, and HVAC systems.

Reliable Performance and Longevity

Equipped with Class F insulation and a high-speed 2880 RPM motor, the blower provides consistent performance under demanding conditions. Its engineered longevity, expected to last up to 10 years, makes it a cost-effective solution for continuous air management in industrial applications.

FAQs of SISW Centrifugal Blower 250 MM X 125 MM:

Q: How is the SISW Centrifugal Blower installed for optimal performance?

A: For best results, the blower should be base mounted on a flat, stable surface near the area requiring ventilation or exhaust. Ensure secure connection to the power source and proper alignment of the inlet and outlet to maximize airflow and efficiency.Q: What are the key advantages of a backward curved fan wheel in this blower?

A: The backward curved design enhances efficiency by reducing air resistance, ensuring higher flow rates, and minimizing energy consumption. This design also helps lower noise levels and prevents dust buildup on the blades, contributing to longer operational life.Q: When should I consider direct drive versus belt driven options for this blower?

A: Direct drive is ideal for applications requiring lower maintenance and consistent speed, while belt driven is suitable for installations needing adjustable speed or handling higher loads. The choice depends on specific airflow requirements and space constraints.Q: Where can the SISW Centrifugal Blower be effectively used?

A: This blower is highly effective in industrial settings such as manufacturing plants, warehouses, and commercial HVAC systems. It excels in applications requiring air ventilation, exhaust, and cooling in environments with ambient temperatures from -10C to 60C.Q: What is the process for routine maintenance of the blower?

A: Routine maintenance involves inspecting the impeller and blades for debris, checking the motor and insulation for wear, lubricating moving parts where applicable, and ensuring secure mounting. Filter cleaning and alignment checks should be performed every few months for optimal performance.Q: What benefits does powder coated mild steel offer for blade material?

A: Powder coating enhances the corrosion resistance of mild steel blades, protecting them from moisture, chemicals, and wear. This prolongs the life of the blower and maintains the efficiency and safety of the air movement system.Q: How does using this blower improve industrial air quality and safety?

A: By efficiently removing airborne contaminants, heat, and stale air, the blower contributes to improved air quality, safer working conditions, and better equipment performance. Its reliable operation and low noise output support healthier and more productive industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 125 MM X 63 MM

Price 600 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Ventilation, Air Exhaust, Industrial Use

Pressure : Other, 600 Pa

Power Source : Other, Electric

Color : Silver Grey

SISW Centrifugal Blower 380 MM X 150 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Industrial Ventilation, Air Handling Units, Dust Collection

Pressure : Other, 80 mm WC

Power Source : Other, Electric

Color : Grey

SISW Centrifugal Blower 180 MM X 75 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Ventilation, Industrial Cooling, Exhaust Systems

Pressure : Other, Up to 50 mm WG

Power Source : Other, Electric

Color : Blue

SISW Centrifugal Blower 380 MM X 125 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Industrial ventilation, exhaust and air handling

Pressure : Other, 40220 mm WC

Power Source : Other, Electric

Color : Blue / Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS