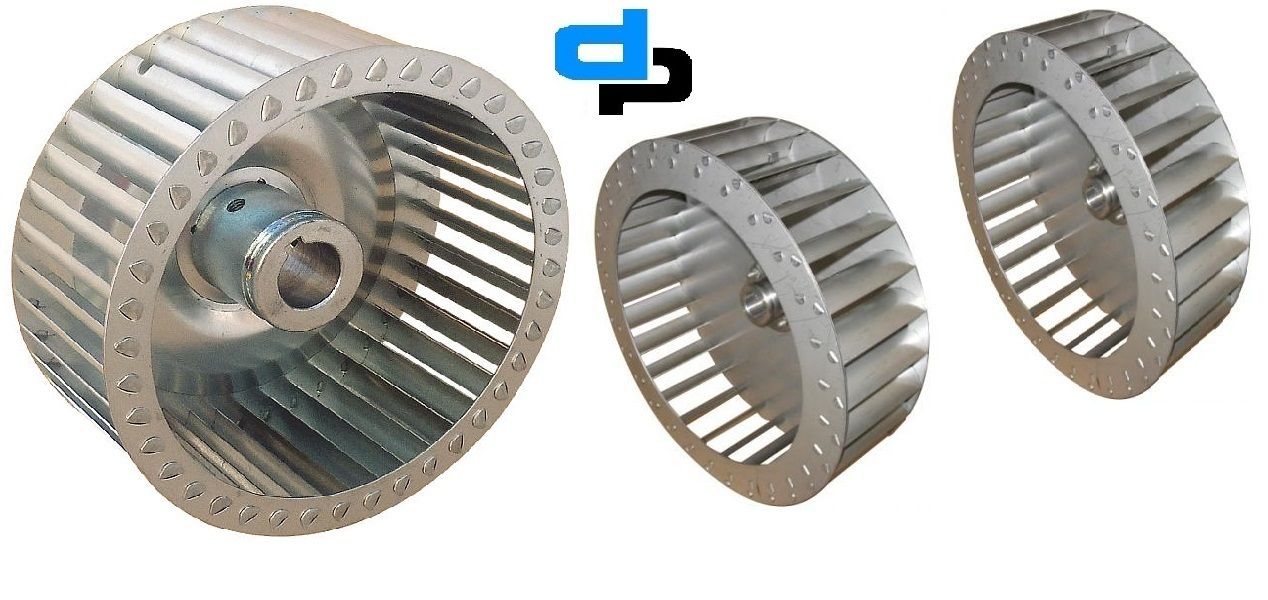

SISW Centrifugal Blower 380 MM X 180 MM

SISW Centrifugal Blower 380 MM X 180 MM Specification

- Max Pressure

- 80 mm WG

- Life Span

- 8-10 years (typical)

- Flow Rate

- 1500-1800 m3/hr

- Output Power

- 2.2 kW

- Power

- 2.2 kW

- Pressure Range

- 50-80 mm WG

- Motor Power

- 3 HP

- Product Type

- Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 1500-1800 m3/hr

- Pressure

- 50-80 mm WG

- Application

- Ventilation, Air Handling, Industrial Exhaust, Dust Collection

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2880 RPM

- Noise Level

- <75 dB(A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- 22 kg

- Dimension (L*W*H)

- 380 mm x 180 mm x 320 mm (approx)

- Color

- Blue

SISW Centrifugal Blower 380 MM X 180 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Tripura, Manipur, Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, South India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Chandigarh, Delhi, Goa, Jammu and Kashmir, Jharkhand, Kerala, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Haryana, Gujarat, Madhya Pradesh, North India, Bihar, Telangana, Central India, Odisha, West India, Chhattisgarh, Karnataka, All India

About SISW Centrifugal Blower 380 MM X 180 MM

SISW Centrifugal Blower 380 MM X 180 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 31 | DP 15 70 | 380 X 180 X 300 | 15 X 7 | 30 MM & 1.25 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Robust Industrial Performance

Designed for demanding industrial environments, the SISW Centrifugal Blower delivers consistent airflow and pressure for applications like ventilation, air handling, and dust extraction. Its backward-curved impeller and direct-coupled motor ensure energy efficiency and reliable function.

Durable Construction and Easy Mounting

Built from high-quality mild steel and coated with protective PU paint, this blower is both resilient and corrosion-resistant. Foot mounting makes installation straightforward and stable, while its compact form factor allows for integration into diverse setups.

Efficient and Quiet Operation

With a three-phase, 2880 RPM motor and sealed ball bearings, the blower operates smoothly at peak performance but with noise levels below 75 dB(A). The TEFC enclosure and Class F insulation contribute to extended motor life and safe, low-maintenance usage.

FAQs of SISW Centrifugal Blower 380 MM X 180 MM:

Q: How does the SISW Centrifugal Blower improve industrial ventilation systems?

A: This blower supplies a high-volume airflow (up to 1800 m3/hr) at a steady pressure, making it ideal for effective heat dissipation, air circulation, and the removal of airborne particulates in industrial settings.Q: What are the main benefits of the backward-curved impeller design?

A: The backward-curved impeller enhances energy efficiency, produces higher static pressure, and resists clogging caused by dust or debris, making it suitable for dust collection and exhaust applications.Q: When should the sealed ball bearings be maintained or replaced?

A: Thanks to their sealed design, the bearings are largely maintenance-free during regular operation. If unusual noise or vibration is detected, a professional inspection is advised, typically every 12 years depending on usage intensity.Q: Where can the SISW Centrifugal Blower be installed?

A: It is suitable for installation in factories, warehouses, process plants, and HVAC systems requiring reliable ventilation or dust extraction, provided the ambient temperature does not exceed 80C.Q: What is the process for installing and connecting the blower?

A: Mount the unit securely using the foot-mounting base, align the inlet and outlet with ductwork (sizes: 180 mm inlet, 180 x 100 mm outlet), and connect to a compatible three-phase (415 V, 50 Hz) electrical supply using the direct coupled method.Q: Is the blower suitable for continuous, heavy-duty operation?

A: Yes, the robust mild steel body, PU paint finish, TEFC enclosure, and Class F insulation ensure dependable performance and longevity under rigorous, continual use.Q: What is the typical lifespan and maintenance expectation for this blower?

A: With proper installation and occasional checks, the blower typically lasts 810 years, requiring minimal maintenance due to its durable components and sealed bearings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 250 MM X 125 MM

Price 1800 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Industrial Air Ventilation, Exhaust, Cooling, HVAC

Noise Level : Less than 80 dB

Flow Rate : 500900 m3/h

Weight : 13 Kg

SISW Centrifugal Blower 180 MM X 75 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Ventilation, Industrial Cooling, Exhaust Systems

Noise Level : Less than 75 dB

Flow Rate : 350 m/h

Weight : 7 kg (Approx.)

SISW Centrifugal Blower 150 MM X 75 MM

Price 800 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Ventilation, Dust Extraction, Air Handling Unit

Noise Level : <85 dB(A)

Flow Rate : 700 CFM

Weight : 8 kg

SISW Centrifugal Blower 530 MM X 200 MM

Price 15000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Ventilation, Industrial, HVAC

Noise Level : 70 80 dB

Flow Rate : 2800 to 3500 m/hr

Weight : 40 kg (approx)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS