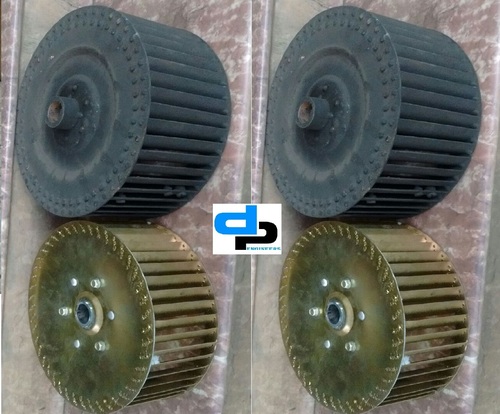

SISW Centrifugal Blower 280 MM X 100 MM

SISW Centrifugal Blower 280 MM X 100 MM Specification

- Power

- 1.5-2 HP

- Life Span

- 5-7 Years (Approx)

- Output Power

- 1.5-2 HP

- Pressure Range

- 60-80 mm WC

- Max Pressure

- 80 mm WC

- Motor Power

- 1.5 HP / 2 HP

- Flow Rate

- 900-1200 CFM

- Product Type

- Single Inlet Single Width (SISW) Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 900-1200 CFM

- Pressure

- 60-80 mm WC

- Application

- Ventilation, Exhaust, Cooling, Industrial Air Handling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2900 RPM

- Noise Level

- Below 85 dB

- Power Source

- Electric

- Voltage

- 220-415 V

- Weight

- Approx. 24 kg

- Dimension (L*W*H)

- 280 mm x 100 mm (Impeller Size)

- Color

- Silver/Grey

SISW Centrifugal Blower 280 MM X 100 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Manipur, Meghalaya, Andaman and Nicobar Islands, Daman and Diu, South India, Central India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Uttarakhand, Chhattisgarh, All India

About SISW Centrifugal Blower 280 MM X 100 MM

SISW Centrifugal Blower 280 MM X 100 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| | OD X HT X ID | OD X HT | MM & INCHES | ||

| 22 | DP 11 40 | 280 X 100 X 236 | 11 X 4 | 12.70 MM ( 1/2'' ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Efficient Industrial Air Movement

Engineered for high performance, the SISW Centrifugal Blower utilizes a backward curved impeller to ensure maximum airflow efficiency with reduced noise. Its robust steel construction and advanced powder coating guarantee durability in harsh operating conditions, making it suitable for a spectrum of industrial applications.

Adaptable and Reliable Design

The blower accommodates both single phase and three phase electrical inputs, addressing diverse operational requirements. Its IP54 enclosure safeguards internal components against dust and moisture, while belt-driven configuration enhances reliability and service life. The unit performs consistently in challenging environments and applications.

Versatile Application

Ideal for use in HVAC, industrial ovens, exhaust systems, cooling, and dust collection, this blower offers a dependable solution for maintaining optimal air quality and temperature control. With a manageable size and weight, it integrates seamlessly into new or existing setups, supporting a wide range of industrial air handling tasks.

FAQs of SISW Centrifugal Blower 280 MM X 100 MM:

Q: How is the SISW Centrifugal Blower 280 MM X 100 MM typically installed?

A: This blower features base-mounted installation, allowing for secure and stable placement on flat surfaces. It supports both single phase and three phase setups, making it suitable for integration into various industrial and HVAC systems.Q: What are the key benefits of the backward curved impeller design?

A: The backward curved impeller enhances energy efficiency and reduces noise while maintaining high airflow. This design is particularly effective in achieving a stable pressure range (60-80 mm WC) for applications requiring steady air movement.Q: When should I use this blower for my application?

A: It is best employed in scenarios demanding robust ventilation, exhaust, cooling, or dust collection. The blowers high airflow and pressure capabilities make it ideal for industrial ovens, HVAC, and workshops requiring efficient particulate removal or air movement.Q: Where is this centrifugal blower most commonly used?

A: The blower is widely used in industrial settings across India, particularly in environments such as factories, commercial kitchens, manufacturing plants, and facilities requiring efficient air handling solutions for dust, heat, or fumes.Q: What process should I follow to ensure long service life of this blower?

A: For optimal longevity, ensure regular cleaning of the impeller and housing, inspect the belt drive for tension and wear, and verify that the induction motor operates within its specified voltage and current range. Scheduled maintenance can help preserve its 5-7 year life span.Q: How does the powder-coated finish benefit this blower?

A: The powder-coated finish provides enhanced resistance to corrosion, wear, and harsh industrial environments. This protective layer prolongs the operational life of the blower and maintains its structural integrity under varying temperature and humidity conditions.Q: What is the typical usage capacity and noise level of this model?

A: The blower operates with a flow rate of 900-1200 CFM and maintains a noise level below 85 dB, making it suitable for environments where efficient yet relatively quiet air movement is required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 380 MM X 150 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2800 RPM

Flow Rate : Up to 1350 m/hr

Color : Grey

Weight : Approx. 24 Kg

SISW Centrifugal Blower 150 MM X 50 MM

Price 650 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2800 RPM

Flow Rate : 300 CMH

Color : Blue

Weight : 4.5 kg

SISW Centrifugal Blower 250 MM X 100 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2800 RPM

Flow Rate : 5001100 m/hr

Color : Grey

Weight : Approx. 17 kg

SISW Centrifugal Blower 250 MM X 125 MM

Price 1800 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2880 RPM

Flow Rate : 500900 m3/h

Color : Blue/Grey

Weight : 13 Kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS