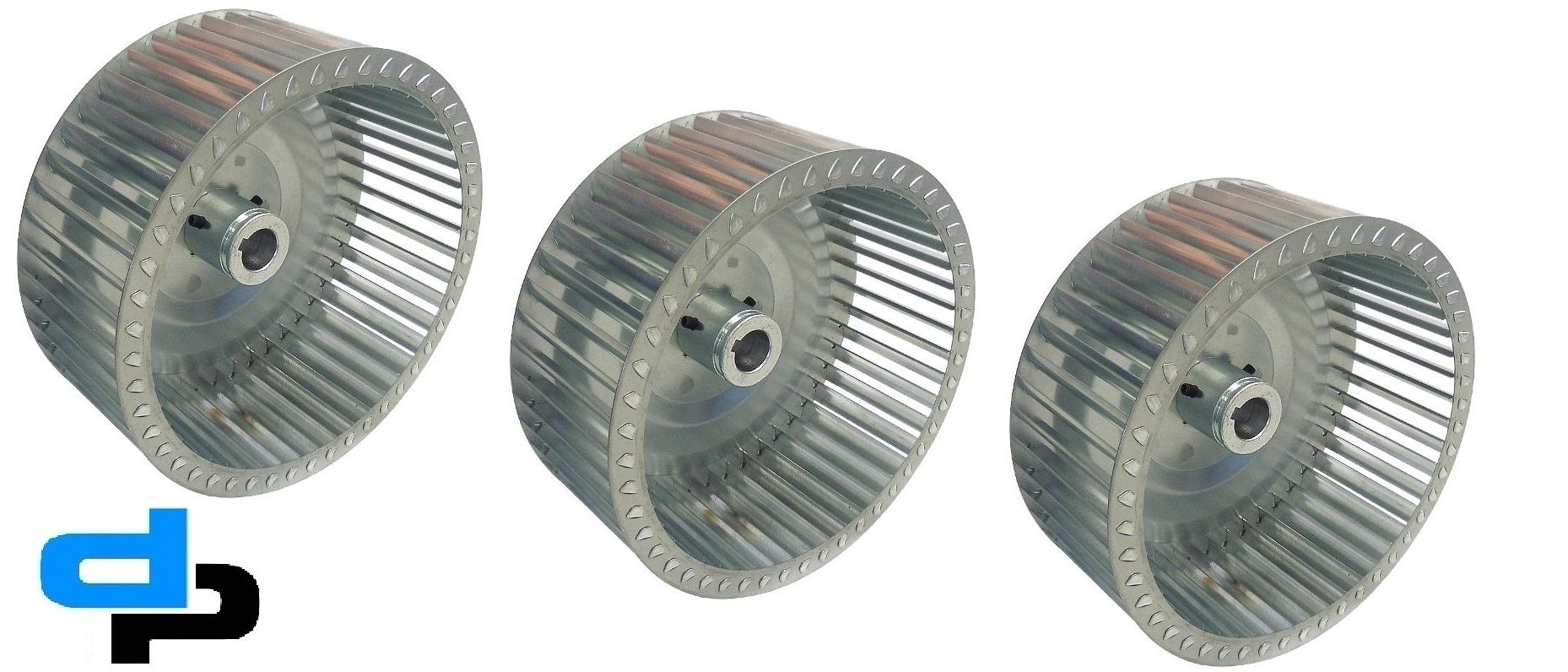

SISW Centrifugal Blower 200 MM X 75 MM

SISW Centrifugal Blower 200 MM X 75 MM Specification

- Pressure Range

- 30 to 60 mm WG

- Max Pressure

- 60 mm WG

- Flow Rate

- 400 CFM

- Motor Power

- 0.37 kW

- Output Power

- 0.37 kW

- Life Span

- 7-10 Years

- Power

- 0.5 HP

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 400 CFM

- Pressure

- Up to 60 mm WG

- Application

- Ventilation, Air Exhaust, Dust Collection, Industrial Cooling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 230 V AC

- Weight

- Approx. 8 kg

- Dimension (L*W*H)

- 200 mm x 75 mm

- Color

- Silver/Gray

SISW Centrifugal Blower 200 MM X 75 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Andhra Pradesh, Kerala, Central India, Odisha, All India

About SISW Centrifugal Blower 200 MM X 75 MM

SISW Centrifugal Blower 200 MM X 75 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

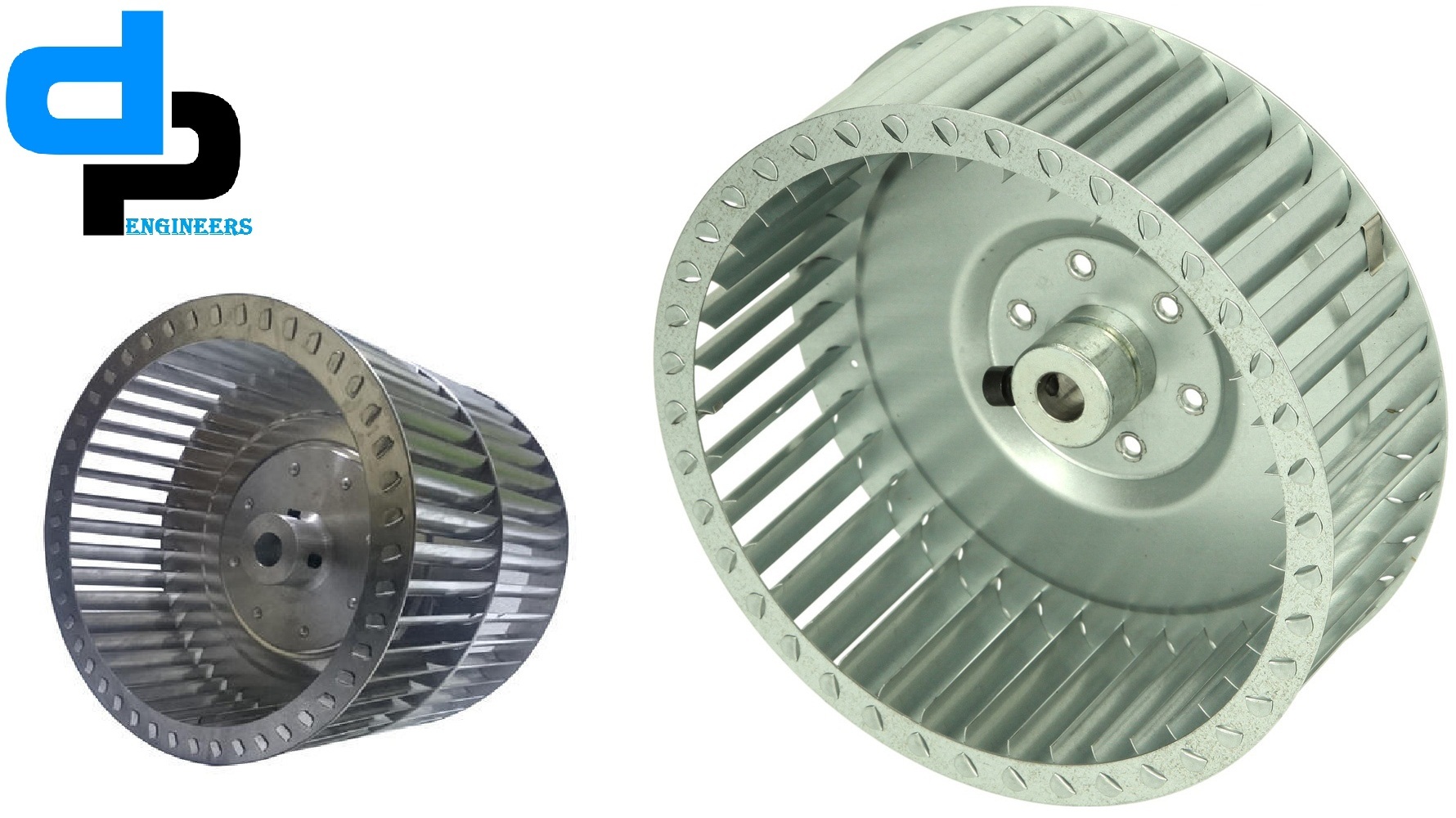

| 13 | DP 8 30 | 200 X 75 X 158 | 8 X 3 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Exceptional Air Delivery and Efficiency

This centrifugal blower stands out for its highly efficient forward curved blade impeller, which maximizes air delivery while maintaining low energy consumption. With a robust direct drive system and high-speed motor, it meets demanding industrial ventilation and dust collection needs without compromising performance.

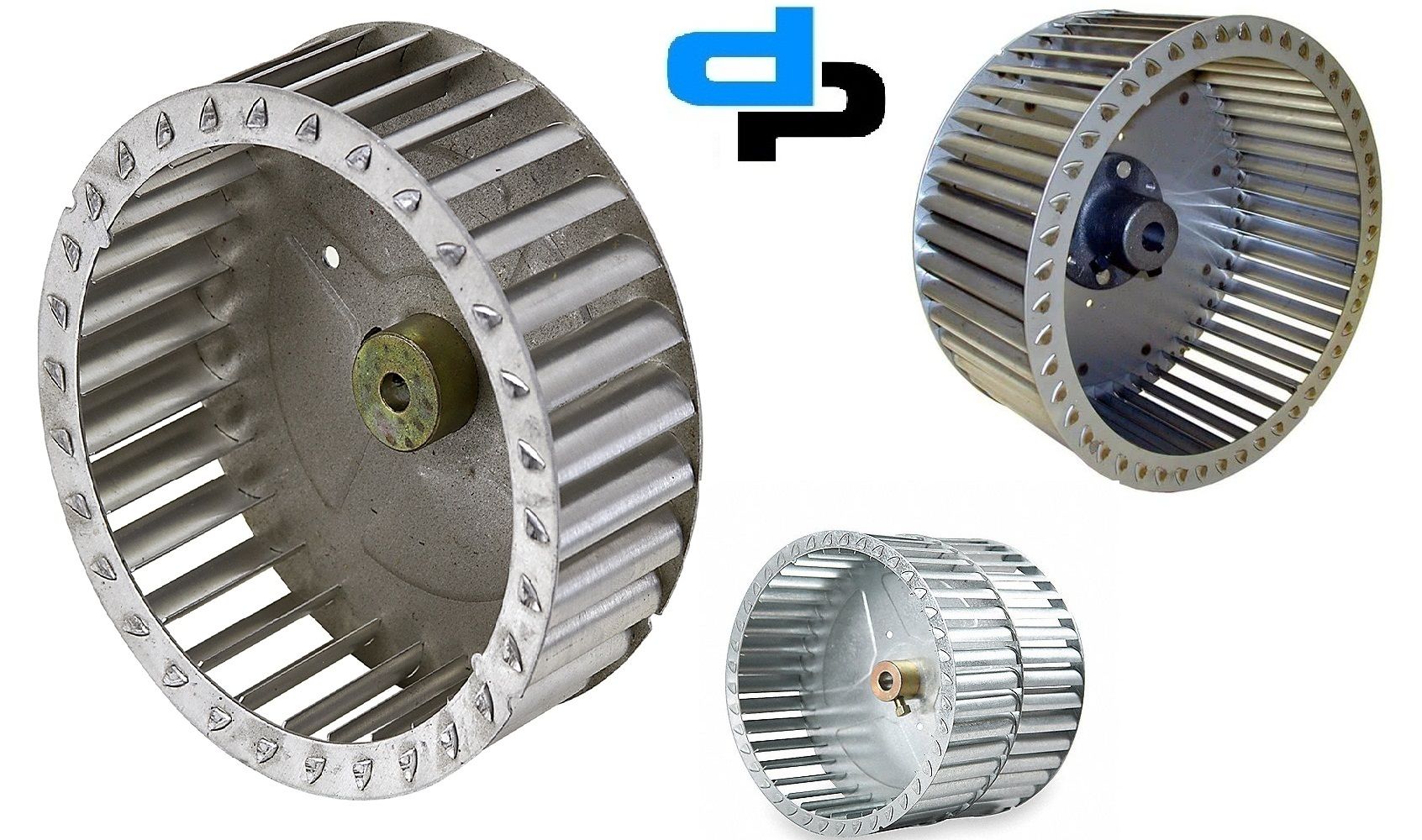

Built for Reliability and Safety

Constructed with powder-coated mild steel and incorporating thermal overload protection, this blower offers outstanding longevity and resilience. The base-mounted design ensures secure installation, while the reduced noise level below 80 dB provides a comfortable working environment.

Versatile Applications Across Industries

Its versatile performance makes the SISW centrifugal blower suitable for ventilation, industrial cooling, air exhaust, and dust collection systems. Its temperature tolerance up to 80C and adaptable mounting allow for effective integration into diverse industrial setups throughout India.

FAQs of SISW Centrifugal Blower 200 MM X 75 MM:

Q: How do I install the SISW Centrifugal Blower 200 MM X 75 MM?

A: Installation is straightforward due to its base-mounted design. Secure the blower on a flat, stable surface, connect the electrical wiring to a 230 V AC single-phase supply, and ensure proper alignment with ductwork or air handling systems for optimal performance.Q: What industrial applications is this blower suitable for?

A: This blower is ideal for ventilation, air exhaust, dust collection, and industrial cooling tasks, making it efficient for factories, workshops, and other commercial environments that require powerful air movement or filtration.Q: When should I consider using thermal overload protection?

A: Thermal overload protection is built into the motor to prevent overheating during intensive operation. It activates automatically when electrical or mechanical stress risks occur, ensuring safe and extended blower life.Q: Where can I use this blower safely given its temperature range?

A: The blower is engineered for safe operation up to 80C, allowing installation in environments with elevated ambient temperatures, such as manufacturing floors, paint booths, and industrial kitchens.Q: What is the process for routine maintenance of this blower?

A: Routine maintenance involves periodic inspection of the impeller and housing for dust or debris, checking the electrical connections, and ensuring that the motor runs smoothly without excessive vibration or noise. Lubrication should be performed as specified in the manual.Q: How does the blower benefit my facilitys air management systems?

A: Its high air delivery and efficiency enhance air movement, reducing airborne contaminants and heat buildup, contributing to improved workplace safety, air quality, and equipment longevity.Q: What are the advantages of the powder-coated steel fan housing?

A: Powder coating provides superior resistance to corrosion, wear, and environmental damage, prolonging the blowers operational lifespan and maintaining its appearance even under harsh industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 250 MM X 125 MM

Price 1800 INR

Minimum Order Quantity : 5 Pieces

Power : 0.51.5 HP

Life Span : 810 Years

Material : other , Mild Steel

Color : Blue/Grey

SISW Centrifugal Blower 180 MM X 75 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Power : 0.5 HP

Life Span : 10,000 hours (Estimated)

Material : other , Mild Steel

Color : Blue

SISW Centrifugal Blower 300 MM X 150 MM

Price 5000 INR

Minimum Order Quantity : 4 Pieces

Power : 2 HP (1.5 kW)

Life Span : 10+ Years (under standard conditions)

Material : other , Mild Steel

Color : Blue / Grey

SISW Centrifugal Blower 530 MM X 150 MM

Price 12500 INR

Minimum Order Quantity : 5 Pieces

Power : 35 HP

Life Span : 810 years (typical with maintenance)

Material : other , Mild Steel (MS), Powder Coated

Color : Blue

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS