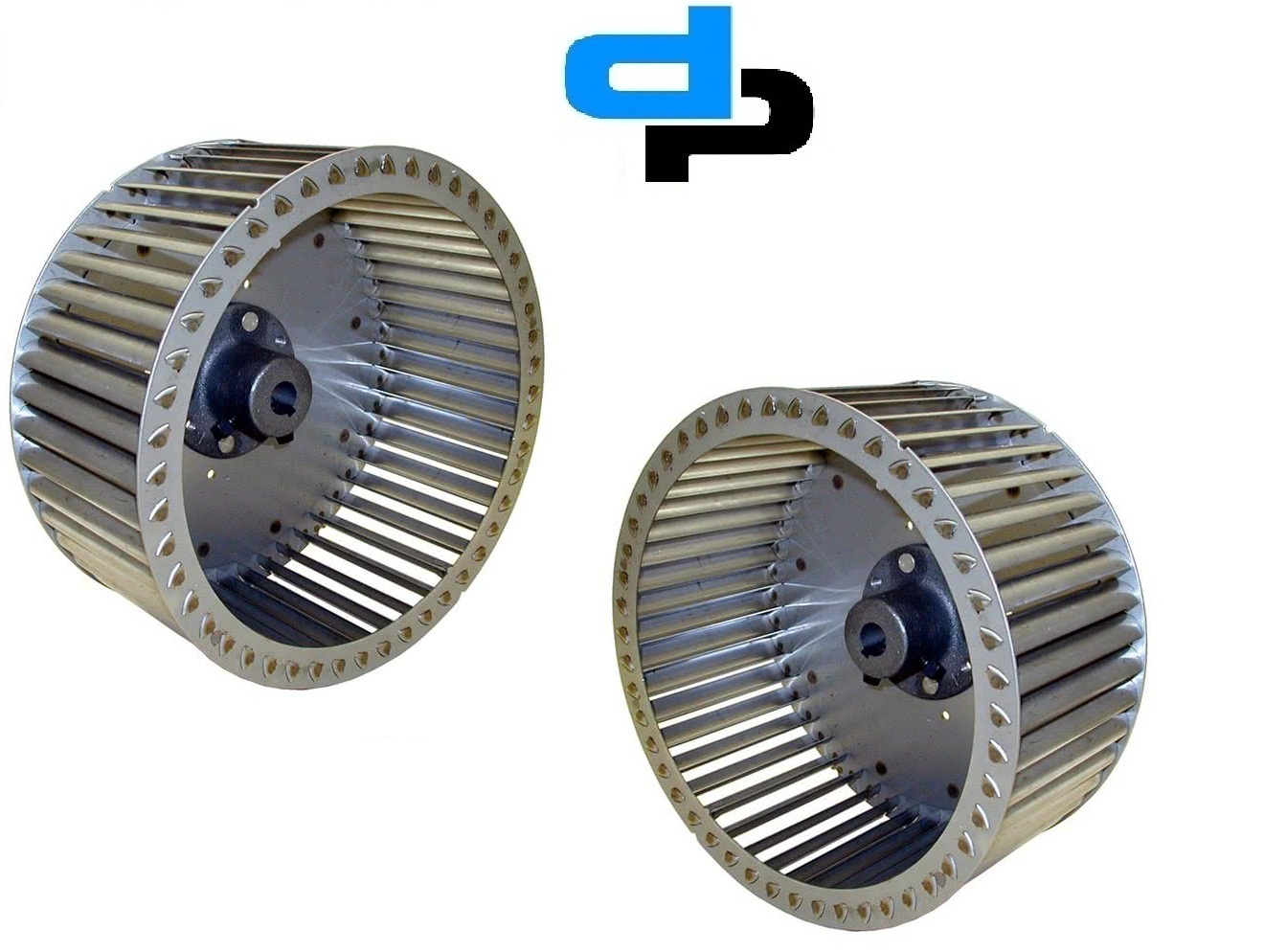

SISW Centrifugal Blower 150 MM X 75 MM

SISW Centrifugal Blower 150 MM X 75 MM Specification

- Power

- 0.5 HP

- Output Power

- 0.37 kW

- Pressure Range

- Up to 330 mm WC

- Motor Power

- 0.37 kW

- Life Span

- 10-12 Years

- Max Pressure

- 330 mm WC

- Flow Rate

- 700 CFM

- Product Type

- Centrifugal Blower

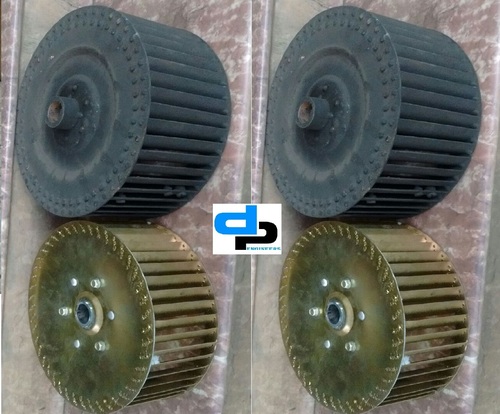

- Material

- Mild Steel

- Capacity

- 700 CFM

- Pressure

- 330 mm WG

- Application

- Ventilation, Dust Extraction, Air Handling Unit

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <85 dB(A)

- Power Source

- Electric

- Voltage

- 220 V

- Weight

- 8 kg

- Dimension (L*W*H)

- 150 mm x 75 mm

- Color

- Blue

SISW Centrifugal Blower 150 MM X 75 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Meghalaya, Pondicherry, South India, East India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Kerala, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Delhi, Gujarat, North India, Andhra Pradesh, Central India, Jharkhand, West India, Chhattisgarh, All India

About SISW Centrifugal Blower 150 MM X 75 MM

SISW Centrifugal Blower 150 MM X 75 MM

SISW CENTRIFUGAL BLOWER

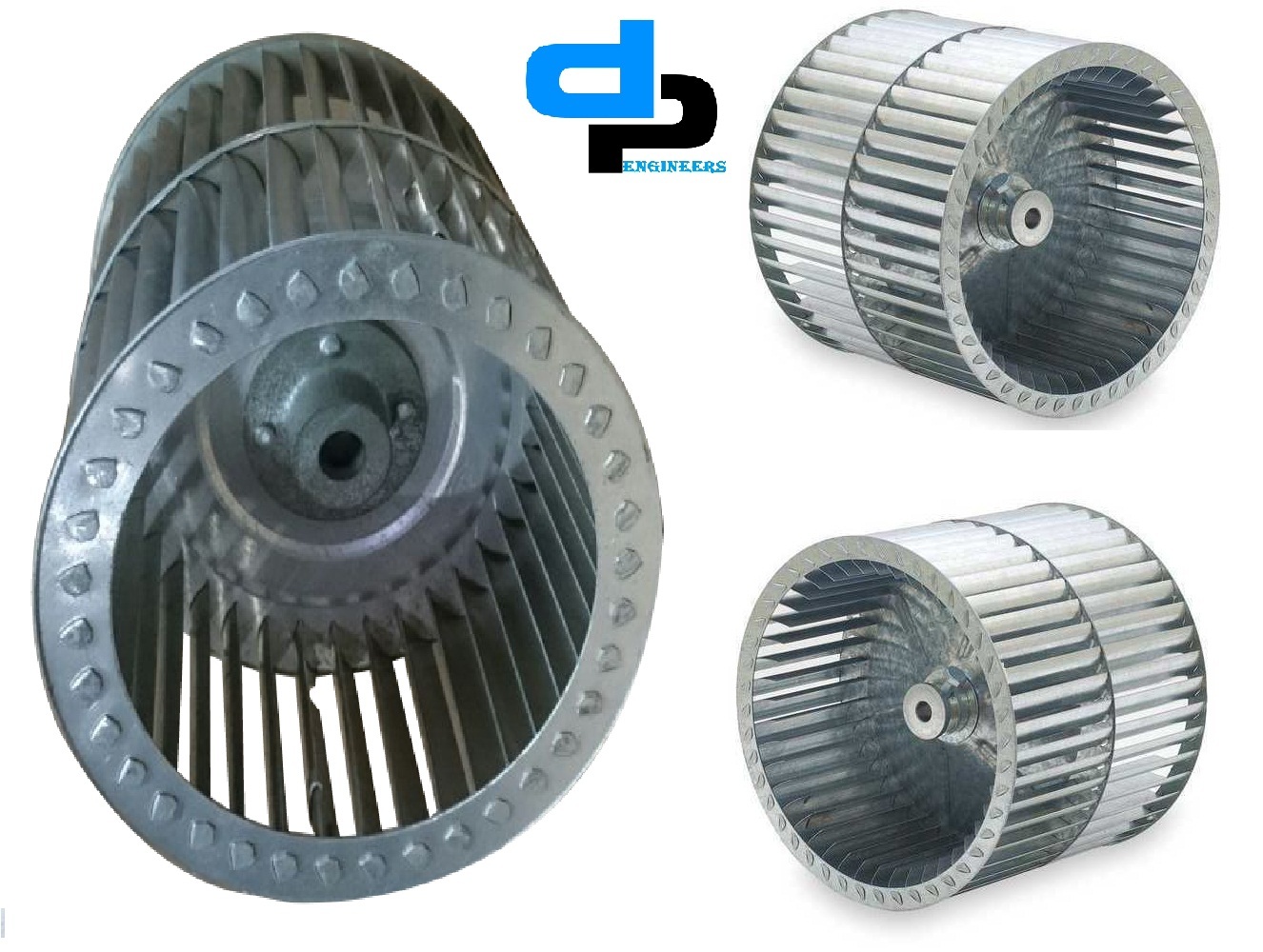

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM X INCHES | |||

| 6 | DP 6 30 | 150 X 75 X 122 | 6 X 3 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : -

- Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90

- INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

High-Efficiency Blower for Multiple Applications

Engineered for versatility, the SISW Centrifugal Blower excels in ventilation, dust extraction, and air handling units. Its backward curved impeller design optimizes airflow and energy performance, while the powder-coated mild steel construction safeguards against corrosion. With a flow rate of 700 CFM and a noise level below 85 dB(A), it is ideal for environments demanding reliable air movement with minimal disruption.

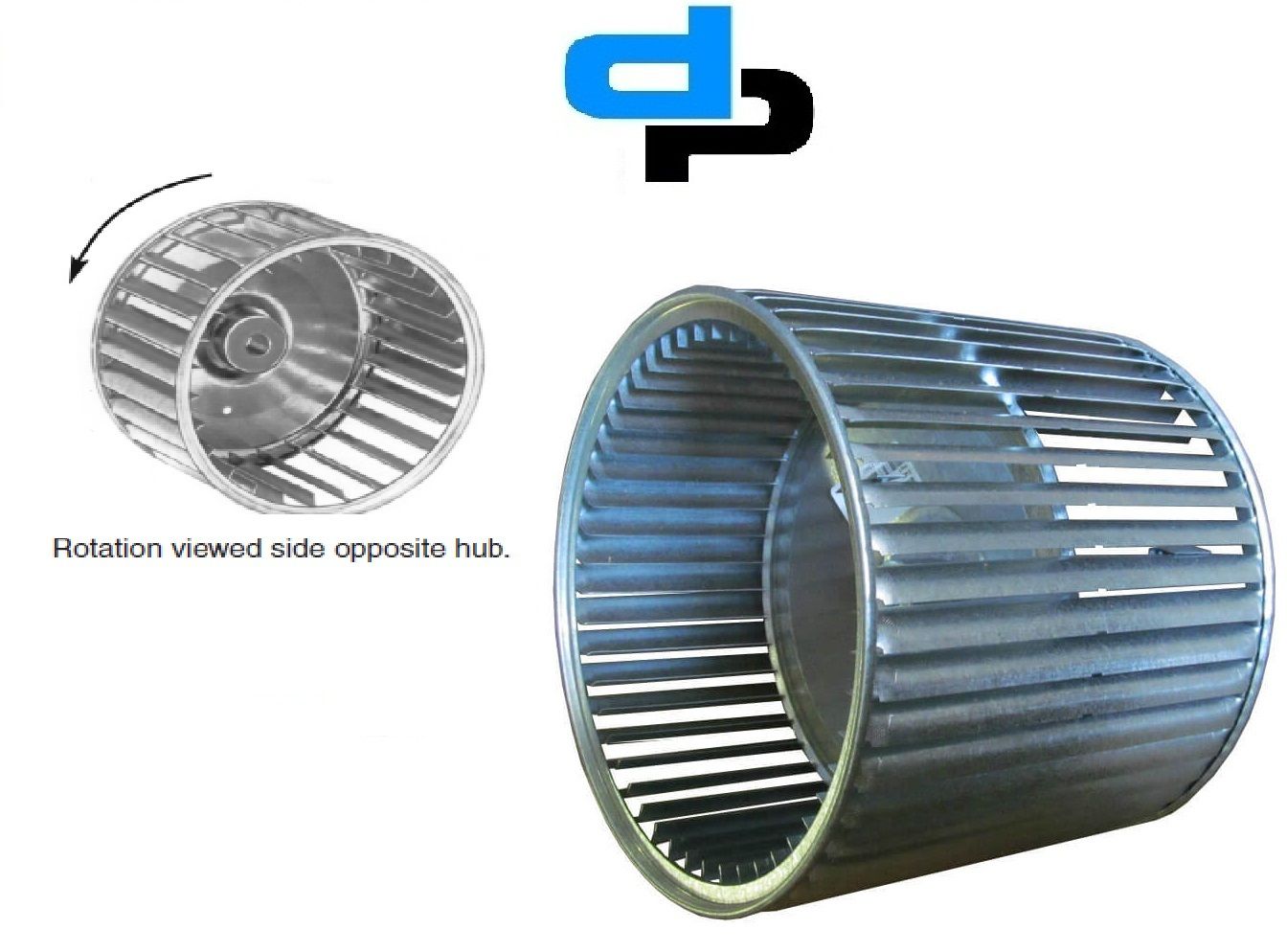

Durable Construction with Reliable Performance

Fitted with sealed ball bearings and a robust IP55 enclosure, the blower withstands intensive use and adverse conditions. Its base-mounted configuration and flange connections simplify installation and maintenance. Operating across a wide ambient temperature range, this blower serves industries needing consistent airflow and long-lasting reliability, with an estimated service life of 1012 years.

FAQs of SISW Centrifugal Blower 150 MM X 75 MM:

Q: How is the SISW Centrifugal Blower typically installed?

A: This blower is base-mounted and uses flange connections for secure installation. It can be easily integrated into existing systems in industrial or commercial settings, making it suitable for ventilation, dust control, and air handling units.Q: What are the benefits of the backward curved impeller design?

A: The backward curved impeller increases efficiency by delivering higher airflow with reduced energy consumption and lower noise levels, making this blower ideal for spaces requiring quiet, consistent air movement.Q: When should I consider manual or automatic control for this blower?

A: Manual control is suitable for straightforward operations or environments with direct supervision, while automatic control is advantageous for systems requiring precise, ongoing airflow management or integration with automated facility operations.Q: Where can the SISW Centrifugal Blower be used?

A: It is designed for use in ventilation systems, dust extraction setups, air handling units, and any application needing reliable, high-efficiency airflow within the specified capacity and pressure range.Q: What process and precautions should be followed for maintenance?

A: Routine inspections of the motor, sealed ball bearings, and powder-coated surfaces are recommended. Maintenance typically involves cleaning, checking for wear, and ensuring correct alignment, contributing to the blowers long lifespan of 1012 years.Q: What is the operating ambient temperature range for this blower?

A: The SISW Centrifugal Blower operates reliably in temperatures from -10C up to +50C, ensuring dependable performance across various climates and industrial environments.Q: How does the high efficiency of this blower benefit users?

A: High efficiency translates to reduced energy costs and improved airflow performance, optimizing operational expenses while delivering consistent output for air handling and ventilation needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 280 MM X 100 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2900 RPM

Life Span : 57 Years (Approx)

Material : other , Mild Steel

Max Pressure : 80 mm WC

SISW Centrifugal Blower 150 MM X 50 MM

Price 650 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2800 RPM

Life Span : 57 Years

Material : other , Mild Steel

Max Pressure : 70 mm WG

SISW Centrifugal Blower 230 MM X 90 MM

Price 1100 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2800 RPM

Life Span : 10+ Years under normal operating conditions

Material : other , Mild Steel, Powder Coated

Max Pressure : 1200 Pa

SISW Centrifugal Blower 150 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2800 RPM

Life Span : 710 Years

Material : other , Mild Steel

Max Pressure : 300 mm WG

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS