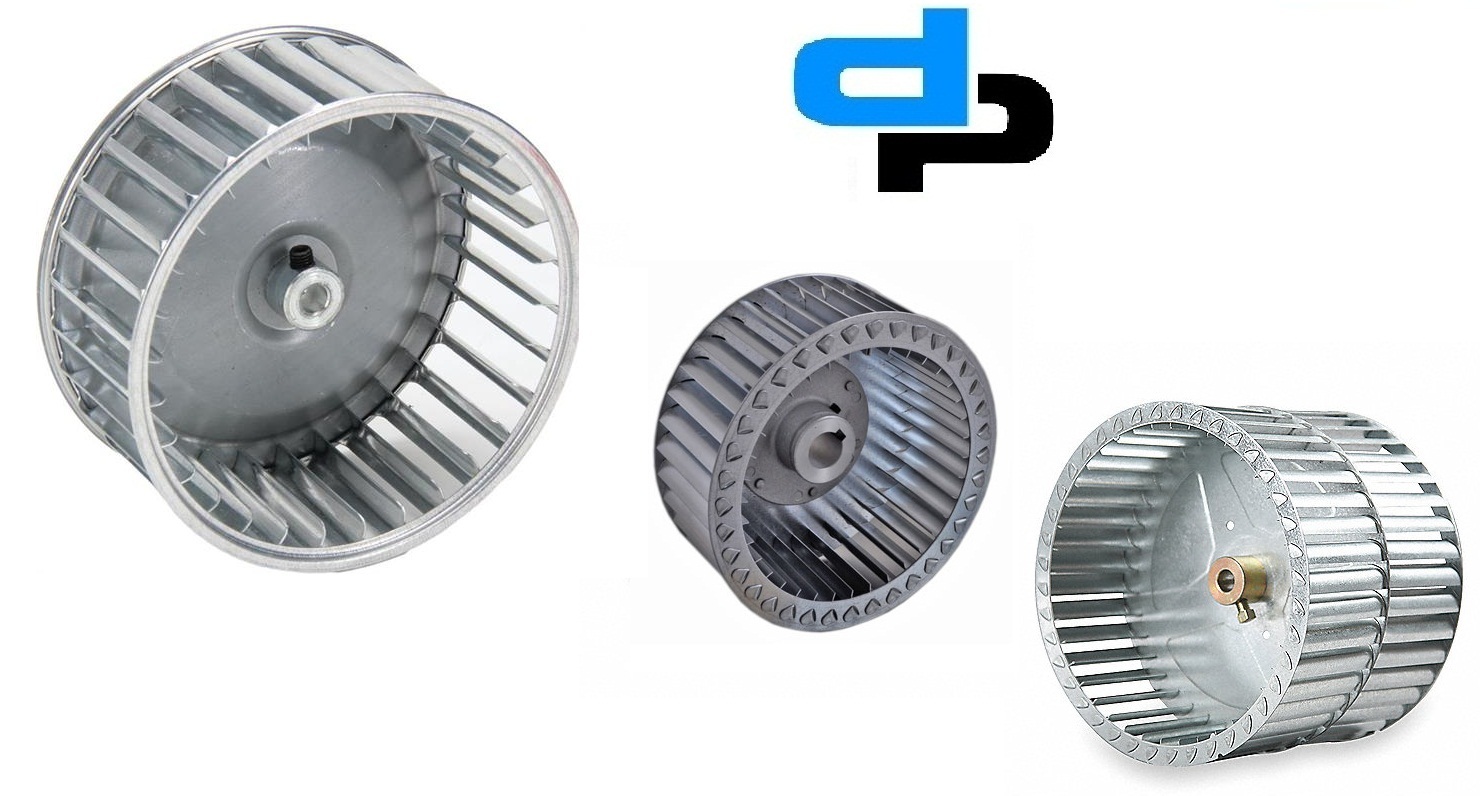

SISW Centrifugal Blower 380 MM X 125 MM

SISW Centrifugal Blower 380 MM X 125 MM Specification

- Pressure Range

- 40-220 mm WC

- Motor Power

- 3-5 HP

- Life Span

- 8-10 Years

- Flow Rate

- 3500 m/hr

- Output Power

- 3.5 kW

- Power

- 3.5 kW

- Max Pressure

- 220 mm WC

- Product Type

- Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 3500 m/hr

- Pressure

- 40-220 mm WC

- Application

- Industrial ventilation, exhaust and air handling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- 75 dB (A)

- Power Source

- Electric

- Voltage

- 380 V

- Weight

- 35 kg

- Dimension (L*W*H)

- 380 mm x 125 mm

- Color

- Blue / Grey

SISW Centrifugal Blower 380 MM X 125 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Tripura, Pondicherry, South India, North India, East India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Punjab, Rajasthan, Sikkim, Tamil Nadu, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Gujarat, Telangana, Andhra Pradesh, Central India, Odisha, West India, Chhattisgarh, All India

About SISW Centrifugal Blower 380 MM X 125 MM

SISW Centrifugal Blower 380 MM X 125 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 29 | DP 15 50 | 380 X 125 X 300 | 15 X 5 | 30 MM & 1.25 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

High-Efficiency Industrial Air Handling

This centrifugal blower is designed to deliver powerful airflow for demanding industrial applications. Its backward curved impeller and direct drive system enable consistent and efficient air movement for ventilation and exhaust purposes. With a maximum pressure of 220 mm WC and a substantial flow rate, it easily meets the requirements for large-scale fabrication plants, workshops, and warehouses.

Robust Construction and Long Service Life

Manufactured with high-quality mild steel, the SISW Centrifugal Blower resists corrosion and provides reliable service, even in challenging environments. The ball bearing assembly and durable components ensure stable operation, reducing maintenance needs and extending equipment life to 810 years. Its blue/grey finish and compact form further contribute to its engineering excellence.

FAQs of SISW Centrifugal Blower 380 MM X 125 MM:

Q: How is the SISW Centrifugal Blower typically installed in an industrial setting?

A: The blower is base mounted and requires placement on a stable surface, with electrical connections made to its three-phase motor. It is suitable for indoor industrial environments and can be integrated into existing air handling or exhaust ductwork.Q: What types of industrial applications is this blower most suitable for?

A: It is ideal for industrial ventilation, exhaust systems, and general air handling applications, such as maintaining air quality in factories, workshops, or warehouses.Q: When should the blower be used for optimal performance and longevity?

A: For best results, operate the blower within its specified limitsup to 70C and at pressures between 40 and 220 mm WC. Routine inspections and periodic cleaning of the impeller and housing will help maintain efficiency.Q: Where can this blower be sourced and who can benefit from it?

A: This centrifugal blower is available through exporter, manufacturer, supplier, and trader channels in India. It benefits industries seeking efficient, reliable ventilation and exhaust solutions.Q: What process does the centrifugal blower use to ensure effective air movement?

A: It utilizes a backward curved impeller design, which enhances airflow efficiency and stability by minimizing turbulence and energy loss, enabling high-capacity air movement at lower noise levels.Q: How does the blowers construction contribute to its operational benefits?

A: Its mild steel body provides strength and corrosion resistance, while the ball bearing support ensures smooth, quiet operation. The direct drive mechanism reduces belt-related maintenance and improves energy transfer.Q: What are the primary benefits of using this centrifugal blower?

A: Users receive dependable, high-volume air handling, reduced maintenance needs due to robust construction, low operating noise (75 dB), and energy-efficient performanceall critical for long-term industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 165 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Life Span : 810 years

Application : Other, Industrial ventilation, Exhaust, Air circulation

Power : 0.37 kW

Frequency (MHz) : 50 Hz

SISW Centrifugal Blower 230 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Life Span : 57 Years (approx.)

Application : Other, Industrial ventilation, Air cooling, HVAC, Exhaust systems

Power : 0.37 kW

Frequency (MHz) : 50 Hz

SISW Centrifugal Blower 610 MM X 250 MM

Price 16000 INR

Minimum Order Quantity : 5 Pieces

Life Span : 15 Years (under standard conditions)

Application : Other, Industrial ventilation, HVAC, Dust Collection

Power : 5 HP

Frequency (MHz) : 50 Hz

SISW Centrifugal Blower 530 MM X 200 MM

Price 15000 INR

Minimum Order Quantity : 5 Pieces

Life Span : 8 10 years

Application : Other, Ventilation, Industrial, HVAC

Power : 2.2 kW

Frequency (MHz) : 50 Hz

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free