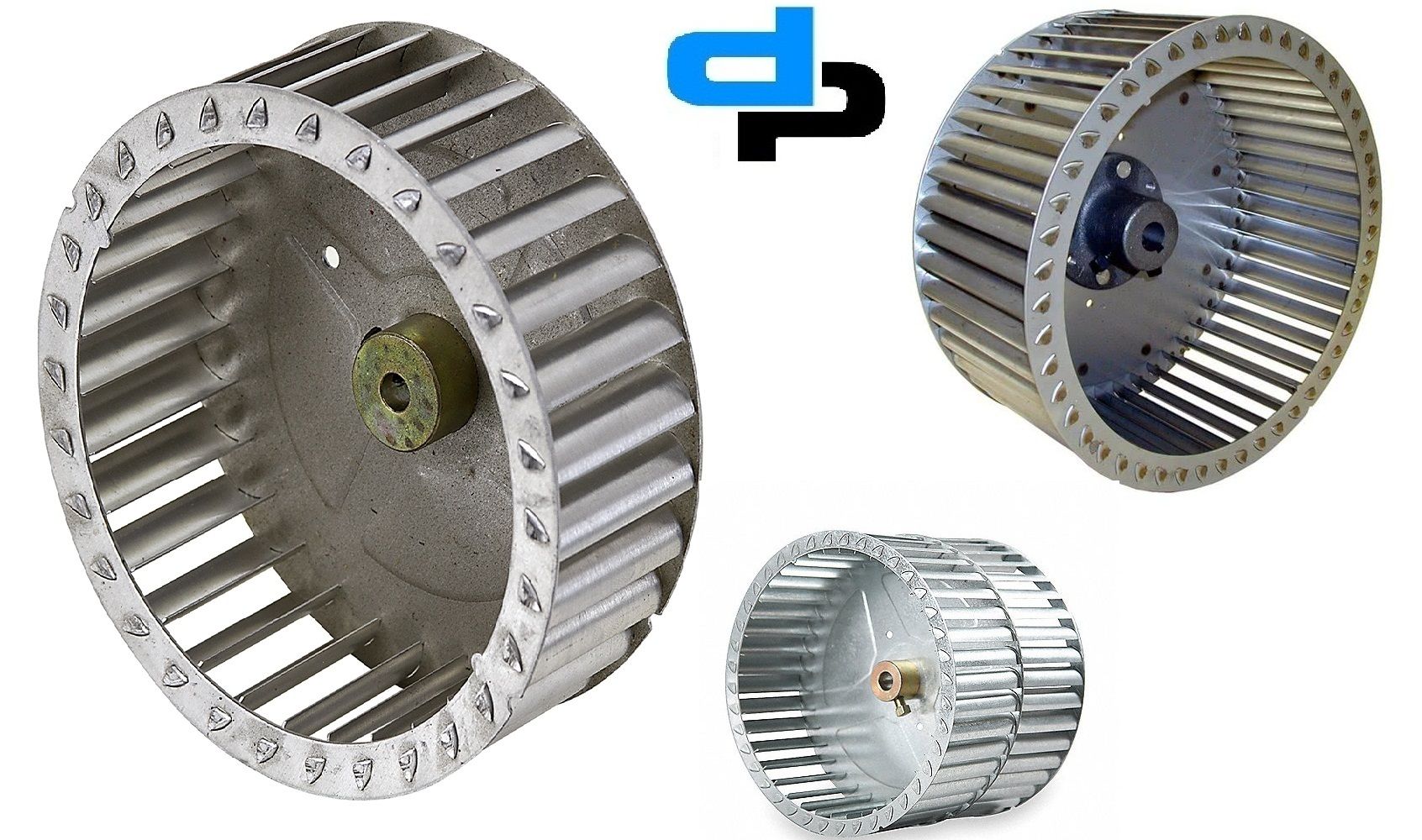

SISW Centrifugal Blower 530 MM X 200 MM

SISW Centrifugal Blower 530 MM X 200 MM Specification

- Max Pressure

- 120 mm WG

- Flow Rate

- 2800 to 3500 m/hr

- Output Power

- 2.2 kW

- Life Span

- 8 10 years

- Pressure Range

- 50 120 mm WG

- Motor Power

- 3 HP

- Power

- 2.2 kW

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 2800 3500 m/hr

- Pressure

- 90 mm WG

- Application

- Ventilation, Industrial, HVAC

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- 70 80 dB

- Power Source

- Electric

- Voltage

- 220 415 V AC

- Weight

- 40 kg (approx)

- Dimension (L*W*H)

- 530 mm x 200 mm x 400 mm

- Color

- Grey

SISW Centrifugal Blower 530 MM X 200 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Manipur, Meghalaya, South India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Tripura, West Bengal, Uttarakhand, Daman and Diu, All India, Lakshadweep, Uttar Pradesh, Haryana, North India, Telangana, East India, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh

About SISW Centrifugal Blower 530 MM X 200 MM

SISW Centrifugal Blower 530 MM X 200 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

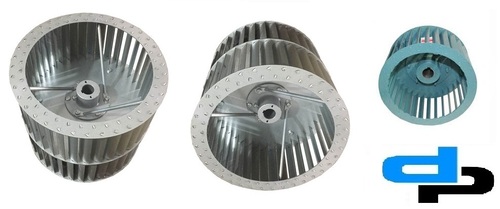

| 36 | DP 21 80 | 530 X 200 X 430 | 21 X 8 | 40 MM & 1.5 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

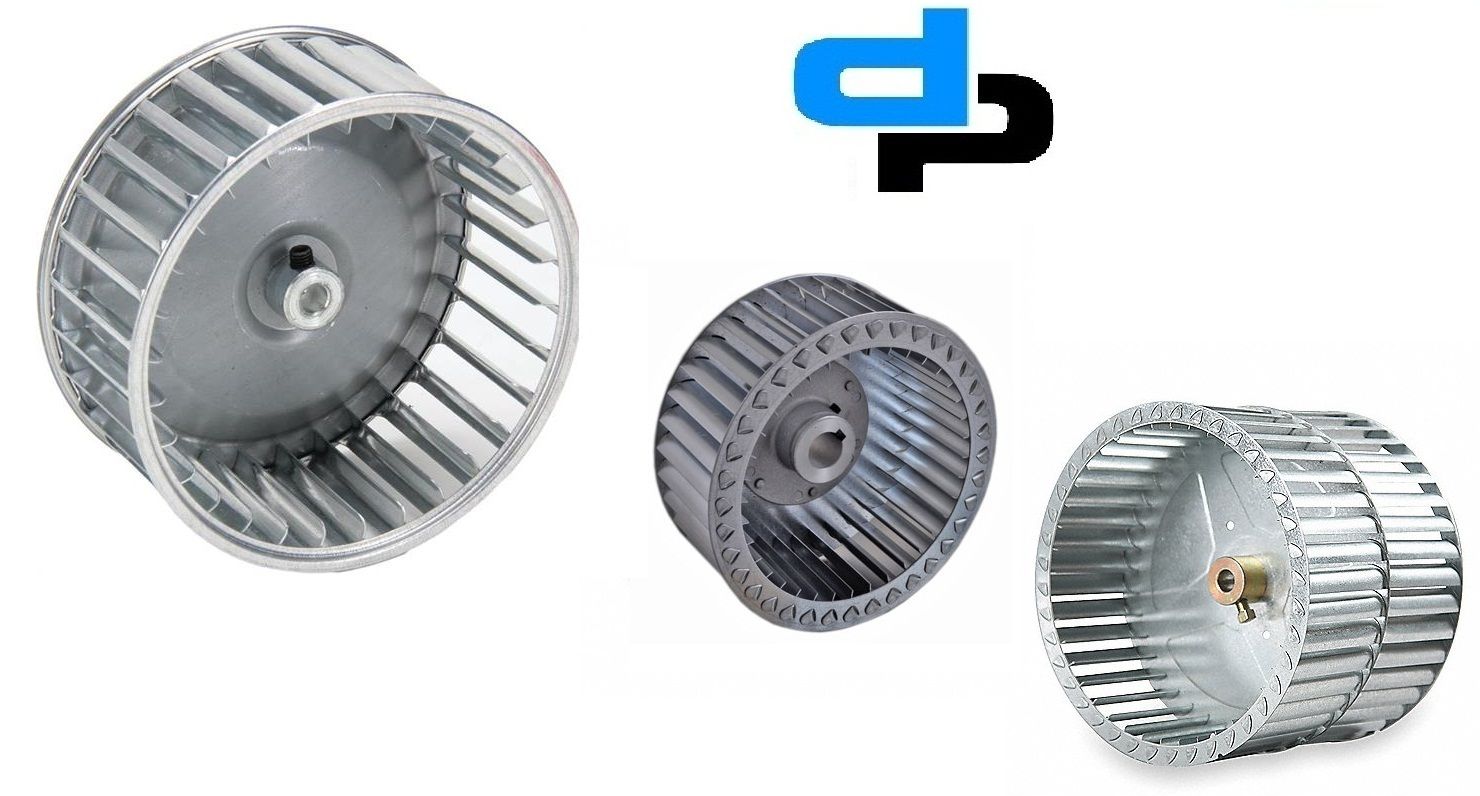

Engineered for Versatility

This centrifugal blower is designed to meet the demanding requirements of industrial, ventilation, and HVAC systems. Its adaptable construction, with belt or direct drive configuration, allows it to handle a wide range of airflow and pressure needs. The forward-curved impeller ensures efficient air movement, backed by a robust mild steel build and powder-coated finish for durability.

Reliable Performance and Protection

With an IP55 rating and Class F insulation, the SISW Centrifugal Blower guarantees consistent operation even in challenging environments. Its three-phase motor runs at 1440 RPM, ensuring stable airflow within a pressure range of 50 to 120 mm WG. The blower is suitable for continuous operation at ambient temperatures from -10C to 60C, promising a long lifespan and minimal maintenance.

FAQs of SISW Centrifugal Blower 530 MM X 200 MM:

Q: How should the SISW Centrifugal Blower be installed for optimal operation?

A: The blower should be base-mounted on a stable, level surface, ensuring proper alignment of the belt or direct drive. It must be connected via its flanged inlet for secure airflow integration. Allow ample clearance for maintenance access and ensure that electrical connections match the specified 220415 V, 50 Hz, three-phase supply.Q: What types of applications are best suited for this blower model?

A: This blower is ideal for ventilation, industrial air movement, and HVAC systems, particularly in settings requiring reliable airflow and pressure management. Its robust construction and high capacity make it suitable for factories, commercial buildings, and process industries.Q: When should maintenance be performed on the blower?

A: Routine maintenance is recommended every 36 months, including checking belt tension (if belt drive), inspecting electrical connections, cleaning the impeller, and ensuring the enclosure is debris-free. Regular inspection helps maintain peak performance and extends the blowers operational life.Q: Where can the SISW Centrifugal Blower be used considering its noise and environmental tolerances?

A: With a noise level of 7080 dB and the ability to operate in temperatures from -10C to 60C, the blower can be deployed both indoors and in sheltered outdoor settings across industrial and commercial sites, provided noise control measures are in place if required.Q: What process does the blower use to achieve efficient airflow?

A: The forward-curved impeller design generates consistent, efficient airflow by minimizing resistance and optimizing movement of large air volumes. The motors 1440 RPM speed further ensures steady output across specified pressure and flow ranges.Q: How does the blower benefit users in long-term industrial applications?

A: Thanks to its durable mild steel construction and powder-coated finish, the blower offers corrosion resistance and a lifespan of 810 years. Its IP55-rated enclosure and Class F insulation enhance operational reliability even in harsh industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 610 MM X 250 MM

Price 16000 INR

Minimum Order Quantity : 5 Pieces

Pressure : Other, 90 mm WC

Output Power : 3.7 kW

Power Source : Other, Electric

Weight : 48 Kg

SISW Centrifugal Blower 200 MM X 100 MM

Price 1050 INR

Minimum Order Quantity : 7 Pieces

Pressure : Other, 80 mm WC

Output Power : 0.75 HP

Power Source : Other, Electric

Weight : Approx. 12 kg

ISW Centrifugal Blower 100 MM X 63 MM

Price 550 INR

Minimum Order Quantity : 5 Pieces

Pressure : Other, 50 mm to 100 mm (WG)

Output Power : 180370 W

Power Source : Other, Electric

Weight : Approx. 57 kg

SISW Centrifugal Blower 180 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Pressure : Other, Up to 45 mm WG

Output Power : 0.37 kW

Power Source : Other, Electric

Weight : 8 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS