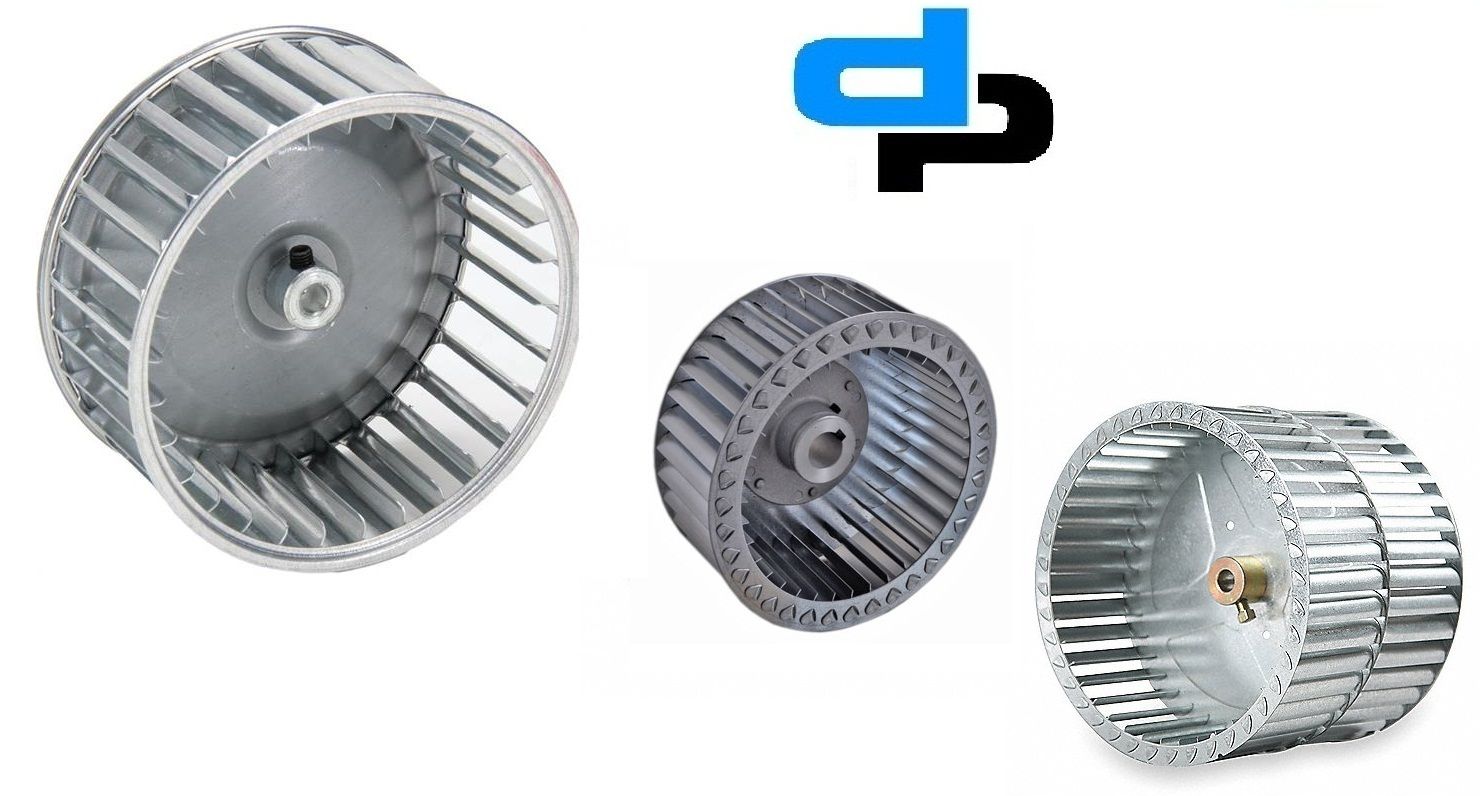

SISW Centrifugal Blower 165 MM X 100 MM

SISW Centrifugal Blower 165 MM X 100 MM Specification

- Output Power

- 0.37 kW

- Life Span

- 8-10 years

- Pressure Range

- 30-60 mm WG

- Max Pressure

- 60 mm WG

- Power

- 0.37 kW

- Motor Power

- 0.5 HP

- Flow Rate

- 200 CFM

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 200 CFM

- Pressure

- 50 mm WG

- Application

- Industrial ventilation, Exhaust, Air circulation

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <80 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- 8 kg

- Dimension (L*W*H)

- 165 mm x 100 mm

- Color

- Blue

SISW Centrifugal Blower 165 MM X 100 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, East India, Assam, Arunachal Pradesh, Bihar, Goa, Jammu and Kashmir, Jharkhand, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Haryana, Delhi, Gujarat, South India, Madhya Pradesh, North India, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, Karnataka, All India

About SISW Centrifugal Blower 165 MM X 100 MM

SISW Centrifugal Blower 165 MM X 100 MM

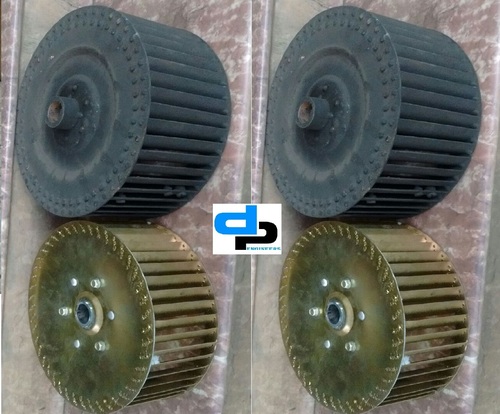

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 9 | DP 65 40 | 165 X 100 X 135 | 6.5 X 4 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Optimized for Industrial Ventilation

Designed to meet the demands of industrial environments, this centrifugal blower ensures efficient ventilation and air exhaust. Its welded steel construction and base-mounted design contribute to stability, while backward curved blades enhance performance in resetting airflow and minimizing energy consumption.

Efficient and Durable Construction

With a heavy gauge mild steel structure and sealed ball bearings, the SISW Centrifugal Blower provides long-term reliability and reduced maintenance. Its robust engineering supports high-speed operation, making it a preferred choice for continuous use in industrial settings.

Customizable Operation and Versatile Applications

The blower supports both clockwise and counterclockwise rotations, fitting varied installation needs. Its wide pressure range and moderate noise levels make it suitable for air circulation, ventilation, and exhaust in factories, warehouses, and commercial facilities.

FAQs of SISW Centrifugal Blower 165 MM X 100 MM:

Q: How is the SISW Centrifugal Blower typically installed in an industrial setup?

A: The blower is base-mounted, allowing secure placement on flat surfaces. Its compact dimensions (165 mm x 100 mm) make it manageable for tight spaces and straightforward integration into existing duct systems.Q: What are the main benefits of using a backward curved impeller blade in this blower?

A: Backward curved impeller blades optimize airflow efficiency, reduce energy consumption, and prevent dust accumulation. This design also contributes to lower noise levels and enhanced durability during prolonged operation.Q: When should the centrifugal blower be maintained or serviced?

A: Routine inspection is suggested every 6 months to check bearing condition and overall performance. Thanks to sealed ball bearings and welded steel construction, maintenance requirements are minimal, enhancing reliability over its 8-10 year life span.Q: Where is this centrifugal blower most effectively used?

A: It is suitable for industrial settings, including factories, warehouses, and commercial spaces, as well as for ventilation, exhaust, and air circulation systems. Its versatility makes it ideal for environments needing consistent airflow at a pressure range of 30-60 mm WG.Q: What process ensures optimal performance of the blower for ventilation or exhaust?

A: For optimal performance, ensure the blower is installed according to manufacturers specifications, connected to the appropriate power supply, and operated within the recommended ambient temperature range (up to 45C). Periodic inspections will maintain efficiency.Q: How does the noise level of the blower compare with standard industrial models?

A: This blower produces less than 80 dB during operation, which is considered moderate for industrial blowers and suitable for workplaces where noise management is important.Q: What are the advantages of using mild steel for blower construction?

A: Mild steel offers excellent strength and resistance to wear, ensuring the blower adapts well to demanding environments while maintaining structural integrity over time. Its heavy gauge design also facilitates stable operation and extended service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 300 MM X 125 MM

Price 4500 INR

Minimum Order Quantity : 5 Pieces

Power : 0.75 kW

Application : Other, Ventilation, Industrial Dust Collection, Air Handling

Max Pressure : 750 mm WG

Capacity : 10001500 m/hr

SISW Centrifugal Blower 250 MM X 125 MM

Price 1800 INR

Minimum Order Quantity : 5 Pieces

Power : 0.51.5 HP

Application : Other, Industrial Air Ventilation, Exhaust, Cooling, HVAC

Max Pressure : 80 mm WC

Capacity : 500900 CFM

SISW Centrifugal Blower 250 MM X 75 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Power : 1 HP

Application : Other, Industrial ventilation, Air exhaust, Fume extraction, Cooling

Max Pressure : 100 mm WC

Capacity : 600 CFM

SISW Centrifugal Blower 280 MM X 100 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Power : 1.52 HP

Application : Other, Ventilation, Exhaust, Cooling, Industrial Air Handling

Max Pressure : 80 mm WC

Capacity : 9001200 CFM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS