Metallic Filters

Metallic Filters Specification

- Capacity

- As per design requirements

- Media Type

- Wire mesh

- Pressure

- Suitable for low to medium pressure systems

- Cleaning Method

- Reusable, washable

- Efficiency (%)

- 95% and above (varies by grade)

- Flow Rate

- Customizable by application

- Filter Type

- Mesh/Cartridge Type

- Temperature Range

- Up to 300C (depending on material)

- Connecting Type

- Flange, threaded, or customized

- Filtration Grade

- Medium to fine

- Condition

- New

- Material

- Stainless Steel / Mild Steel

- Mesh

- Available in various mesh sizes (customizable)

- Diameter

- Custom sizes available, standard sizes also offered

- Construction

- Rugged metallic mesh construction

- Medium Filter

- Air, Oil, Gas, Liquids

- Weight

- Lightweight, varies with size

- Shape

- Round

- Feature

- High filtration efficiency, durable structure

About Metallic Filters

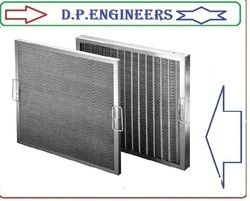

Metallic Filters

Pleated Metal Mesh Filter are pre filters that are designed for general ventilation and air conditioning system applications as well as for electric motors and plenum air for working areas. These are an economical and a very durable option over other pre filter counterparts.

Construction:

- The element is constructed using 5 layer of GI Wire mesh inter spaced with 2 crimpled layers and 3 flat layers

- The media is supported with expanded metal from both sides as reinforcement and housed usually in deep metal frame (custom build sizes are also available on order)

| Dimensions (MM) | Rated Air Flow Capacity(CMH) | Initial Resistance (MM of WC) | |||

| (HXWXD) | @ 1.5M/Sec | @2.54M/Sec | @1.52M/Sec | @2.54M/Sec | |

| 610X610X25 | 2040 | 3400 | 1.7 | 2.8 | |

| 305X305X25 | 1020 | 1700 | 1.7 | 2.8 | |

| 305X305X25 | 510 | 850 | 1.7 | 2.8 | |

| 610X610X50 | 2040 | 3400 | 1.7 | 2.8 | |

| 305X610X50 | 1020 | 1700 | 1.7 | 2.8 | |

| 305X350X50 | 510 | 850 | 1.7 | 2.8 | |

High Durability in Challenging Environments

With a polished and smooth surface finish, these metallic filters withstand corrosive environments and repeated washings, ensuring a long service life. Solid stainless steel or mild steel mesh construction provides durability, allowing use in high-demand industrial sectors, including food processing, chemical plants, and HVAC systems.

Versatile Filtration for Multiple Applications

Available in a range of mesh sizes and customizable diameters, our filters are compatible with oils, gases, liquids, and air, supporting a diverse set of applications. Their high efficiency (95% and above) and adaptability to various flow rates make them suitable for both low and medium pressure systems.

Easy Installation and Reusability

These filters are designed with user convenience in mind, featuring simple installation and replacement processes. Washable and reusable, they deliver significant cost and waste reductions. Multiple connecting types such as flange, threaded, or custom options are supplied to meet different installation needs.

FAQs of Metallic Filters:

Q: How can metallic filters be cleaned and reused?

A: Metallic filters can be removed from their housing and cleaned using methods such as backwashing, ultrasonic cleaning, or chemical soaking. Proper cleaning restores their original efficiency and extends service life, making them a sustainable filtration solution.Q: What benefits do corrosion-resistant metallic filters offer over non-metal alternatives?

A: Corrosion-resistant metallic filters resist rust and chemical degradation, especially in harsh industrial environments. They last longer, maintain efficiency, and reduce replacement frequency, offering cost-effectiveness over non-metal alternatives.Q: When should these filters be replaced or serviced?

A: Filters should be serviced according to the applications maintenance schedule or when there is a noticeable drop in flow rate or filtration efficiency. Regular inspection and cleaning ensure optimal performance and prolong service life; replacement is only necessary if physical damage or irreversible clogging occurs.Q: Where can metallic filters with excellent corrosion resistance be utilized?

A: They are ideal for HVAC systems, industrial filtration, food processing, chemical and petrochemical plants, and any application requiring high durability and corrosion resistance, both indoors and outdoors.Q: What is the installation process for these metallic filters?

A: Installation is straightforward with options for flange, threaded, or customized connections. Filters can be fitted into existing systems, and their lightweight design ensures easy handling during installation and replacement.Q: What types of media can these filters process?

A: These filters are effective for air, oils, gases, and liquids. Their customizable mesh and filtration grade allow them to be tailored for specific media and flow requirements, making them versatile for different industries.Q: How does the customizable design benefit users?

A: Customizable mesh sizes, diameters, and connection types allow users to select or request filters that perfectly match their systems capacity, flow parameters, and filtration needs, ensuring efficient operation and reduced downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Filter Category

Wire Mesh Filter

Condition : New

Material : Stainless Steel

Feature : Corrosion Resistant, Durable Filtration, Precise Pore Size, Easy Installation

Construction : Other, Single Layer/Multiple Layer Welded Mesh

Shape : Round

Filter Type : Wire Mesh Disc Filter

Fresh Air Filter

Condition : New

Material : Galvanized Iron, Aluminum, Stainless Steel (options available)

Feature : High dust holding capacity, Excellent filtration efficiency, Rust resistant matrix, Easy installation, Durable structure

Construction : Other, Robust frame with supported mesh layers

Shape : Rectangular or customized shapes

Filter Type : Fresh Air Pre Filter

Pleated Metal Mesh Filter

Condition : New

Material : Stainless Steel Mesh

Feature : High dirt holding capacity, Long service life, Washable and reusable, Corrosion resistant

Construction : Other, Pleated cylindrical or panel

Shape : Cylindrical/Pleated

Filter Type : Pleated Metal Mesh Filter

Dry Viscous Metallic Air Filters

Condition : New

Material : Metal

Feature : Durable and Resilient

Construction : Metallic Frame, Other

Shape : Rectangular

Filter Type : Dry Viscous Metallic Air Filter

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS