Wire Mesh Filter

Wire Mesh Filter Specification

- Connecting Type

- Press Fit / Threaded

- Capacity

- Customizable

- Filter Type

- Wire Mesh Disc Filter

- Cleaning Method

- Reusable, Washable, Backflush

- Temperature Range

- -20C to 500C

- Efficiency (%)

- Up to 99%

- Flow Rate

- 5-35 L/min (size dependent)

- Media Type

- Solid-Liquid Separation

- Pressure

- Up to 10 Bar

- Filtration Grade

- Medium

- Condition

- New

- Material

- Stainless Steel

- Mesh

- 50 to 500 Mesh (customizable)

- Diameter

- 2 inch (standard), customizable

- Construction

- Single Layer/Multiple Layer Welded Mesh

- Medium Filter

- Water, Air, Oil

- Weight

- 50 g - 150 g (varies by size)

- Shape

- Round

- Feature

- Corrosion Resistant, Durable Filtration, Precise Pore Size, Easy Installation

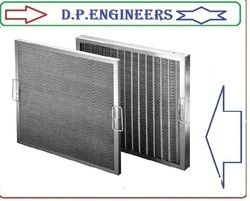

About Wire Mesh Filter

Wire mesh filter

Specification Efficiency

Standard metallic viscous filters have an efficiency of 65% for 20 micron size particles. Metallic filters with an efficiency rating of 65-85% to capture 25 micron to 50 micron size particles are also available on

order. Efficiency can be increased to 85% if the filters are oil wetted.

Frame Type : Available in Flange or Box Type GI,AL.,SS.

Filter media : GI/SS/Aluminum expanded mesh

Face guard : Filter is protected with expanded mesh on both sides

Pressure drop :Initial pressure drop ~1mm wg & recommended final pressure drop is 5-10mm wg

Operating conditions

Filter can withstand temperature >80ºc and relative humidity of 70%. Recommended air velocity is 2m/sec to 2. 5m/sec. Filter is washable and can be washed using water or back air pressure and reused.

Versatile Filtration for Demanding Applications

Designed for a range of industrial environments, our wire mesh filters deliver reliable performance across chemical, food and beverage, and pharmaceutical sectors. Whether used in hydraulic systems or for air and gas filtration, each filter offers precise pore sizing and robust corrosion resistance. With customizable diameters and mesh counts, these filters are tailored for optimum efficiency in challenging conditions.

Durable Construction and Easy Maintenance

Constructed from polished stainless steel, the wire mesh filters are built to last. Their single or multi-layer welded mesh ensures strength under pressures up to 10 bar and temperatures from -20C to 500C. Reusable and washable, maintenance is a breeze, while cleaning methods including backflushing contribute to long-term cost savings and eco-friendly operation.

Comprehensive Customization and OEM Services

Our wire mesh filters accommodate diverse application requirements by offering custom sizes, varied mesh grades, and options for press fit or threaded connections. OEM services are available to manufacturers seeking branded or tailored filtration solutions. Every filter is packaged safely in either a carton or wooden box for secure delivery worldwide.

FAQs of Wire Mesh Filter :

Q: How do I select the appropriate mesh size for my wire mesh filter?

A: Choosing the ideal mesh size depends on your applications filtration requirements. With mesh options ranging from 50 to 500, you should consider the particle size you need to separate from your process fluid. For finer filtration, select a higher mesh count. Our team can assist in identifying the best mesh specification for your needs.Q: What industries can benefit from using these wire mesh filters?

A: Industries including chemical processing, food and beverage, pharmaceuticals, hydraulic systems, and air or gas filtration commonly use our wire mesh filters. Their corrosion resistance and durable construction make them suitable for diverse and demanding environments.Q: When should the wire mesh filter be cleaned or replaced?

A: Cleaning intervals depend on your application and how quickly particles accumulate on the mesh. These filters are designed to be reusable and can be washed or backflushed as needed. We recommend regular inspections and cleaning to maintain optimal performance; replacement is only necessary if the mesh becomes damaged.Q: Where can custom sizes or OEM wire mesh filters be sourced?

A: Custom sizes and OEM wire mesh filters are available directly from us as an exporter, manufacturer, supplier, and trader in India. Contact our sales team with your specifications, and we will assist with customization and bulk ordering.Q: What is the process for installing a wire mesh disc filter?

A: Installation is straightforward due to the filters user-friendly press fit or threaded connection options. Ensure the system is depressurized before installing, then fit the filter as per your systems requirement. Detailed installation guidelines are provided with each shipment.Q: What are the benefits of using stainless steel, polished wire mesh filters?

A: Stainless steel wire mesh filters offer excellent corrosion resistance, durability under high pressure and temperature, and precise particle filtration. The polished surface further extends the filters lifespan and makes cleaning easier, contributing to reduced operational costs and enhanced reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Filter Category

Metallic Filters

Condition : New

Construction : Other, Rugged metallic mesh construction

Feature : High filtration efficiency, durable structure

Filter Type : Mesh/Cartridge Type

Shape : Round

Mesh : Available in various mesh sizes (customizable)

Pleated Metal Mesh Filter

Condition : New

Construction : Other, Pleated cylindrical or panel

Feature : High dirt holding capacity, Long service life, Washable and reusable, Corrosion resistant

Filter Type : Pleated Metal Mesh Filter

Shape : Cylindrical/Pleated

Mesh : Multiple mesh sizes available

Fresh Air Filter

Condition : New

Construction : Other, Robust frame with supported mesh layers

Feature : High dust holding capacity, Excellent filtration efficiency, Rust resistant matrix, Easy installation, Durable structure

Filter Type : Fresh Air Pre Filter

Shape : Rectangular or customized shapes

Mesh : Multilayer wire mesh

Dry Viscous Metallic Air Filters

Condition : New

Construction : Metallic Frame, Other

Feature : Durable and Resilient

Filter Type : Dry Viscous Metallic Air Filter

Shape : Rectangular

Mesh : Fine Metallic Mesh

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS