Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06 Specification

- Display

- External digital/analog (depends on model integration, typically not local)

- Sensor Type

- Wet/Wet Differential Pressure Transmitter

- Grade

- Industrial

- Bourdon Tube

- Not applicable (uses electronic sensing, not bourdon tube)

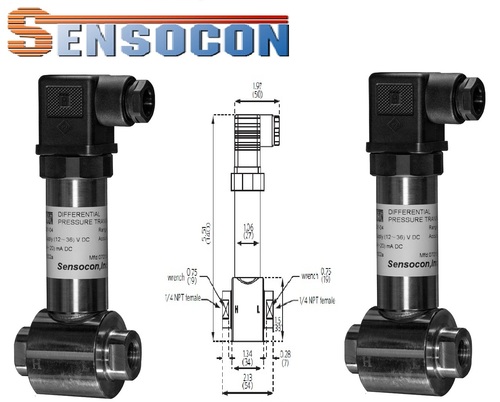

- Outer Size

- Compact enclosure, approx. 120 x 80 x 55 mm

- Thread

- 1/4 NPT Female

- Seal Material

- Viton or Buna (depends on model selection)

- Material

- Aluminum housing, stainless steel wetted parts

- Processing Type

- Electronic sensing and signal processing

- Diameter

- Not specified (rectangular enclosure)

- Mount Type

- Wall or panel mount

- Scale Range

- 0-6 psi differential (Series 251-06)

- Accuracy

- 1.0% Full Scale

- Finishing

- Powder coated or anodized aluminum housing

- Measure Pressure Of

- Liquids and gases

- Accessories

- Mounting hardware, installation manual

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06 Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, South India, East India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Maharashtra, Haryana, Delhi, Gujarat, Madhya Pradesh, North India, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

About Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

Reliable Differential Pressure Monitoring

Engineered for stability and precision, the Series 251-06 ensures accurate differential pressure readings for both liquids and gases. Its electronic sensing design avoids mechanical wear, offering consistent performance in demanding industrial environments where reliability is key.

Flexible Integration and Durable Construction

Featuring a compact enclosure and standard 4-20 mA output, this transmitter is easily integrated into existing control systems. With stainless steel wetted parts and NEMA 4X/IP66 protection, it resists corrosion and ingress, ensuring long operational life even in challenging settings.

FAQs of Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06:

Q: How is the Sensocon Series 251-06 Differential Pressure Transmitter installed for optimal performance?

A: The transmitter can be mounted on a wall or panel using the provided mounting hardware. Process connections are made via 1/4" NPT female ports for both high- and low-pressure inlets, ensuring secure and leak-proof installation.Q: What types of media can this transmitter measure, and what are its wetted materials?

A: The Series 251-06 is designed to measure differential pressure in liquids and gases. Its wetted parts are stainless steel, with seals available in Viton or Buna depending on the selected model, providing chemical compatibility for diverse applications.Q: When should zero and span adjustments be performed on the Series 251-06?

A: Zero and span adjustments, accessible through potentiometers, should be done during initial installation, routine calibration, or when process conditions change to ensure accuracy across the full operating range.Q: Where is the ideal location for installing this transmitter considering environmental protection?

A: Install the transmitter in environments where NEMA 4X (IP66) protection is required, such as industrial areas exposed to dust, moisture, or splashing liquids, to maximize its operational lifespan and performance stability.Q: What process advantages does the electronic sensing design of the Series 251-06 provide?

A: The electronic sensing and signal processing eliminate mechanical wear associated with traditional pressure gauges, ensuring rapid response times (<100 ms), enhanced accuracy, and stable output for efficient process control.Q: How can users benefit from the transmitters compact design and enclosure features?

A: Its compact dimensions (approximately 120 x 80 x 55 mm) facilitate space-saving installation, while the powder-coated or anodized aluminum enclosure offers corrosion resistance and durability in harsh conditions, reducing maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wet Differential Pressure Transmitter-Series251-DP Category

Series 251 - Wet/Wet Differential Pressure Transmitter

Grade : Industrial

Material : Other, Die cast aluminium

Accessories : Mounting Bracket, Bolts, Manual

Processing Type : Other, Calibrated before dispatch

Sensor Type : Wet/Wet Differential Pressure Transmitter

Display : Analog & Digital (Optional)

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-04

Grade : Industrial

Material : Other, Enclosure: Aluminum, Wetted Parts: Stainless Steel/Brass

Accessories : Mounting hardware included, instruction manual

Processing Type : Other, Electronic Pressure Sensing

Sensor Type : Wet/Wet Differential Pressure Transmitter

Display : None (Transmitter output only)

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

Grade : Industrial Grade

Material : Other, Enclosure: Aluminum; Wetted Parts: Stainless Steel 316

Accessories : Standard mounting brackets included

Processing Type : Other, Electronic (Sensorbased)

Sensor Type : Wet/Wet Differential Pressure Transmitter

Display : No display (Transmitter only)

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Grade : Industrial

Material : Other, Aluminum Housing

Accessories : Mounting Hardware Included

Processing Type : Other, Electronic

Sensor Type : Wet/Wet Differential Pressure Transmitter

Display : None (Analog Output)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS