Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05 Specification

- Seal Material

- Viton O-Rings

- Thread

- 1/4 NPT Female

- Sensor Type

- Wet/Wet Differential Pressure Transmitter

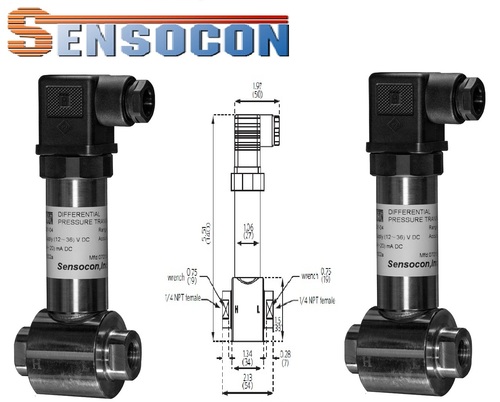

- Outer Size

- Body: 5.59 x 2.04 x 2.37 (142 mm x 52 mm x 60 mm)

- Grade

- Industrial

- Display

- None (Analog Output)

- Material

- Aluminum Housing

- Processing Type

- Electronic

- Mount Type

- Wall Mount

- Scale Range

- 0-5 PSID (0-345 mbar differential)

- Accuracy

- 1.0% Full Scale

- Finishing

- Anodized Aluminum

- Measure Pressure Of

- Liquids and Gases

- Accessories

- Mounting Hardware Included

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05 Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Kerala, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Haryana, Delhi, Gujarat, Madhya Pradesh, North India, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

About Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

The Series 251 wet/wet differential pressure transmitter utilizes a double diaphragm sensor technology that outperforms standard double sensor products in accuracy, reliability and static operating pressure. This differential pressure sensing technology offers 0.25% accuracy with static operating pressures up to 1000 PSI. The Series 251 features 316 stainless steel construction designed to meet NEMA 4X (IP 65) standards. The transmitter also offers exceptional field flexibility with a 5:1 turn down and comes standard with a certificate of calibration.

- Media compatibility: Gas and Liquids compatible with 316SS

- Accuracy: +/- 0.25% F.S.

- Over Pressure: positive - 2x f.S.; negative-1x F.S.

- Working Pressure: 1000 PSI (7MPa)

- Temperature Limits: Operating: -40° to 185°F (-40° to 85°C)Compensated: -4° to 158°F (-20° to 70°C)

- Thermal Effect: +/- 0.028% FS/°F (0.050%FS/°C)

- Stability: +/- 0.5% FS/year

- Power Supply: 12-30 VDC

- Output Signal: 4-20 mA, 2-wire

- Electrical Connetction: mini DIN 43650

- Response Time: 100 ms

- Turn Down: 5:1

- Enclosure Rating: NEMA 4X (IP 65)

- Process Connection: 1/4" NPT female, optional 1/4" G

- Mounting Position Effect:0.1% F.S., can be corrected by zero adjust

- Model Number : 251-05

- Range : 0 - 50 PSI ( 344.7 kPa )

Versatile Industrial Pressure Measurement

Designed for use with both liquids and gases, the Sensocon Series 251-05 is ideal for process industries requiring accurate wet/wet differential pressure measurement. Its broad media compatibility and Viton O-ring sealing enable operation in diverse environments. Suited for wall mounting, its anodized aluminum construction provides resilience in demanding applications.

Reliable Analog Signal and Field Adjustability

With a 4-20 mA two-wire output, the transmitter integrates smoothly with industry-standard control systems. The field-adjustable zero and span enable on-site calibration, assuring optimal performance. Fast response time and high accuracy foster reliable monitoring and enhanced process control.

User-Friendly Installation and Protection

This model is supplied with mounting hardware and features a terminal block for straightforward electrical connection. Its IP65 rating protects against dust and water ingress, making it suitable for indoor and outdoor industrial environments. The 1/4 NPT female thread simplifies plumbing connectivity to process lines.

FAQs of Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05:

Q: How does the Sensocon 251-05 transmitter measure differential pressure?

A: The transmitter uses wet/wet sensing technology to accurately measure the pressure difference between two fluid points. This enables monitoring of both liquids and gases across process lines.Q: What installation process should be followed for this pressure transmitter?

A: The device is wall-mounted using the provided hardware. Connect the 1/4 NPT female ports to your pressure lines and wire the terminal block with a 12-30 VDC power supply as per the wiring diagram, ensuring a tight seal with compatible media.Q: When should field adjustments of zero and span be performed?

A: Adjustments should be made during commissioning or routine maintenance to calibrate the device for optimal accuracy, compensating for installation variances or system changes.Q: Where is it suitable to use the Sensocon 251-05 transmitter?

A: The transmitter is fit for industrial environments, such as chemical plants, HVAC systems, and process industries, where differential pressure monitoring for most liquids and gases is required.Q: What benefits does the IP65 protection class offer?

A: IP65 protection ensures the transmitter is safeguarded against dust and water intrusion, making it reliable for use in harsh or exposed locations.Q: How does the quick response time of less than 5 ms impact usage?

A: The fast response enhances real-time monitoring applications, enabling rapid detection of pressure fluctuations and improved process control.Q: What materials and media are compatible with this transmitter?

A: The anodized aluminum housing, with Viton O-ring seals, allows compatibility with a wide range of liquids and gases; however, strongly corrosive chemicals should be checked against the wetted materials to ensure compatibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wet Differential Pressure Transmitter-Series251-DP Category

Series 251 - Wet/Wet Differential Pressure Transmitter

Accessories : Mounting Bracket, Bolts, Manual

Sensor Type : Wet/Wet Differential Pressure Transmitter

Scale Range : 010 to 04000 mbar (Various Ranges)

Accuracy : 1.0% F.S.

Thread : 1/4 NPT (Male)

Material : Other, Die cast aluminium

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

Accessories : Mounting hardware, installation manual

Sensor Type : Wet/Wet Differential Pressure Transmitter

Scale Range : 06 psi differential (Series 25106)

Accuracy : 1.0% Full Scale

Thread : 1/4 NPT Female

Material : Other, Aluminum housing, stainless steel wetted parts

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

Accessories : Standard mounting brackets included

Sensor Type : Wet/Wet Differential Pressure Transmitter

Scale Range : Selectable ranges up to 250 psi differential

Accuracy : 0.5% of full scale

Thread : Process Connection: 1/4 NPT Female

Material : Other, Enclosure: Aluminum; Wetted Parts: Stainless Steel 316

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-04

Accessories : Mounting hardware included, instruction manual

Sensor Type : Wet/Wet Differential Pressure Transmitter

Scale Range : 04 Bar (differential)

Accuracy : 1.0% FS (Full Scale)

Thread : 1/4 NPT (Female)

Material : Other, Enclosure: Aluminum, Wetted Parts: Stainless Steel/Brass

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS