Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03 Specification

- Display

- No display (Transmitter only)

- Sensor Type

- Wet/Wet Differential Pressure Transmitter

- Grade

- Industrial Grade

- Seal Material

- Viton O-rings (standard)

- Thread

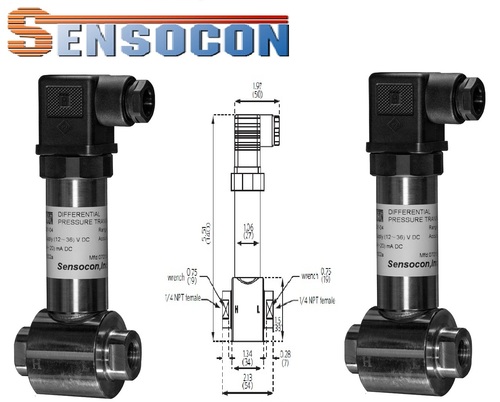

- Process Connection: 1/4 NPT Female

- Outer Size

- Compact Rectangular Housing, Approx. 4.7 x 3.1 x 2.4 (120 x 80 x 60mm)

- Material

- Enclosure: Aluminum; Wetted Parts: Stainless Steel 316

- Processing Type

- Electronic (Sensor-based)

- Diameter

- Not Applicable (Rectangular Enclosure)

- Mount Type

- Wall or surface mounting

- Scale Range

- Selectable ranges up to 250 psi differential

- Accuracy

- 0.5% of full scale

- Finishing

- Epoxy-coated aluminum enclosure

- Measure Pressure Of

- Liquids and gases (Wet/Wet applications)

- Accessories

- Standard mounting brackets included

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03 Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, Maharashtra, Haryana, Gujarat, Delhi, Uttar Pradesh, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

The Series 251 wet/wet differential pressure transmitter utilizes a double diaphragm sensor technology that outperforms standard double sensor products in accuracy, reliability and static operating pressure. This differential pressure sensing technology offers 0.25% accuracy with static operating pressures up to 1000 PSI. The Series 251 features 316 stainless steel construction designed to meet NEMA 4X (IP 65) standards. The transmitter also offers exceptional field flexibility with a 5:1 turn down and comes standard with a certificate of calibration.

- Media compatibility: Gas and Liquids compatible with 316SS

- Accuracy: +/- 0.25% F.S.

- Over Pressure: positive - 2x f.S.; negative-1x F.S.

- Working Pressure: 1000 PSI (7MPa)

- Temperature Limits: Operating: -40° to 185°F (-40° to 85°C)Compensated: -4° to 158°F (-20° to 70°C)

- Thermal Effect: +/- 0.028% FS/°F (0.050%FS/°C)

- Stability: +/- 0.5% FS/year

- Power Supply: 12-30 VDC

- Output Signal: 4-20 mA, 2-wire

- Electrical Connetction: mini DIN 43650

- Response Time: 100 ms

- Turn Down: 5:1

- Enclosure Rating: NEMA 4X (IP 65)

- Process Connection: 1/4" NPT female, optional 1/4" G

- Mounting Position Effect:0.1% F.S., can be corrected by zero adjust

- Model Number : 251-03

- Range : 0 - 15 PSI ( 103 kPa )

Precise and Reliable Pressure Measurement

Sensocons 251-03 transmitter is designed for accurate wet/wet differential pressure measurement in both liquids and gases. Its robust construction and stainless steel wetted components ensure compatibility with various industrial fluids, supporting reliable operation even in challenging environments.

Adaptable to Diverse Applications

Choose from multiple pressure ranges, up to 250 psid, to tailor the transmitter for specific system requirements. Field-adjustable zero and span let you calibrate the device on-site with accessible potentiometers, ensuring maximum flexibility for different installations.

Industrial Protection and Easy Installation

The epoxy-coated aluminum enclosure with IP65 (NEMA 4X) rating offers outstanding protection against dust and water, safeguarding the transmitter in harsh operating conditions. Wall or surface mounting is straightforward, aided by provided standard brackets and a compact rectangular housing.

FAQs of Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03:

Q: How do I install the Sensocon Series 251-03 Wet/Wet Differential Pressure Transmitter?

A: This transmitter can be mounted on a wall or other surfaces using the included standard brackets. The compact housing with 1/4 NPT female process connections allows for quick integration into most piping systems. Electrical connection uses a screw terminal block for secure wiring.Q: What pressure media can the Series 251-03 measure?

A: Designed for wet/wet differential measurement, the transmitter accurately senses pressure differences in both liquids and gases. Its stainless steel 316 wetted parts and Viton O-rings provide compatibility with a wide range of aggressive and clean substances.Q: When should I adjust the zero and span on this transmitter?

A: Zero and span adjustment should be performed during installation or when recalibrating for a new pressure range. This process uses accessible potentiometers and ensures the transmitter is accurately configured to your applications requirements.Q: Where is the Series 251-03 best suited for use?

A: With its IP65 (NEMA 4X) protection rating, epoxy-coated enclosure, and industrial-grade construction, the transmitter is ideal for demanding environments, such as chemical plants, HVAC systems, water treatment facilities, and industrial process control applications.Q: What process connection type does this device use?

A: The Series 251-03 is equipped with 1/4 NPT female process connections, making it compatible with standard industrial fittings and simplifying integration with existing piping or machinery.Q: How quickly does the transmitter respond to pressure changes?

A: The device features an impressively fast response time of less than 5 milliseconds, enabling it to deliver real-time feedback in dynamic systems and applications.Q: What are the main benefits of using this differential pressure transmitter?

A: Key advantages include high accuracy (0.5% of full scale), selectable pressure ranges, rugged industrial design, rapid response, and easy, reliable installation. These features ensure optimal performance and long-term reliability in wet/wet pressure monitoring applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wet Differential Pressure Transmitter-Series251-DP Category

Series 251 - Wet/Wet Differential Pressure Transmitter

Grade : Industrial

Scale Range : 010 to 04000 mbar (Various Ranges)

Display : Analog & Digital (Optional)

Sensor Type : Wet/Wet Differential Pressure Transmitter

Thread : 1/4 NPT (Male)

Material : Other, Die cast aluminium

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

Grade : Industrial

Scale Range : 06 psi differential (Series 25106)

Display : External digital/analog (depends on model integration, typically not local)

Sensor Type : Wet/Wet Differential Pressure Transmitter

Thread : 1/4 NPT Female

Material : Other, Aluminum housing, stainless steel wetted parts

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-04

Grade : Industrial

Scale Range : 04 Bar (differential)

Display : None (Transmitter output only)

Sensor Type : Wet/Wet Differential Pressure Transmitter

Thread : 1/4 NPT (Female)

Material : Other, Enclosure: Aluminum, Wetted Parts: Stainless Steel/Brass

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Grade : Industrial

Scale Range : 05 PSID (0345 mbar differential)

Display : None (Analog Output)

Sensor Type : Wet/Wet Differential Pressure Transmitter

Thread : 1/4 NPT Female

Material : Other, Aluminum Housing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS