Gas Turbine Filters

Gas Turbine Filters Specification

- Connecting Type

- Flange / Clamp / Customized Fit

- Capacity

- Suitable for industrial/utility scale gas turbines

- Temperature Range

- -20C to +80C

- Filtration Grade

- F5-F9, EPA, HEPA (as per selection)

- Flow Rate

- 1000-50000 m/h (model dependent)

- Media Type

- Non-woven synthetic or glass fiber

- Filter Type

- Air Filter for Gas Turbine

- Pressure

- High tolerance up to 350 Pa

- Cleaning Method

- Replaceable / Pulse jet cleanable options

- Efficiency (%)

- Up to 99.97%

- Condition

- New

- Material

- Galvanized Steel, Stainless Steel, Synthetic Fiber

- Mesh

- Fine mesh available

- Diameter

- Customizable as per requirement

- Construction

- Robust, Rigid Frame

- Medium Filter

- Synthetic Fiber/Glass Fiber

- Weight

- Standard - 5-15 kg (varies with model)

- Shape

- Cylindrical / Panel / Cartridge

- Feature

- High dust holding capacity, Low maintenance, High efficiency

- Maximum Differential Pressure

- 450 Pa

- Rated Air Velocity

- 2.5 m/s standard

- Gasket Type

- EPDM/Rubber/PU

- Usage/Application

- Power plants, Gas turbines, Industrial ventilation systems

- Color

- White/grey (as per supply)

- Service Life

- 9-18 months (depending on environment)

- End Cap Material

- Aluminium / Polyurethane

- Replacement Interval

- Recommended 6-12 months

- Mounting

- Vertical / Horizontal

About Gas Turbine Filters

Optimal Use, Reliable Application, Straightforward Direction

Gas Turbine Filters deliver refined air purification for gas turbines in utility-scale power plants and complex industrial ventilation systems. Designed for either vertical or horizontal mounting, these filters adapt effortlessly to varying plant layouts. Users benefit from swift and simple installationjust connect via flange or clamp and align as required. Enjoy low maintenance; replacement or cleaning is direct and hassle-free, keeping plant operations efficient and interruption-free.

Steady Global Arrival, Competitive Rate, Valuable Offers

Our Gas Turbine Filters arrive regularly in diverse export markets, meeting industrial demand in regions like India, the Middle East, and Southeast Asia. Major FOB ports include Mumbai and Chennai, ensuring timely and secure shipment. Domestically, we offer attentive aftersales service and comprehensive distribution to all main industrial hubs in India. Take advantage of our competitive rates and exclusive offers designed specifically for high-demand industrial partners.

FAQs of Gas Turbine Filters:

Q: How do I install Gas Turbine Filters for optimal performance?

A: Install the filters in either a vertical or horizontal orientation, using the recommended flange, clamp, or customized fittings. Make sure the airflow direction matches the indicated markings for maximum filtration efficiency.Q: What is the replacement interval for these filters in gas turbines?

A: It is recommended to replace the filters every 612 months, depending on environmental conditions and operational demands. Regular inspection ensures continued high performance and longevity.Q: What materials are used in the construction of these gas turbine filters?

A: Our filters feature a robust, rigid frame made from galvanized steel or stainless steel, with filtering media composed of synthetic fiber or glass fiber, ensuring durability and high efficiency.Q: Where are your main export and domestic markets for Gas Turbine Filters?

A: We export primarily to markets in India, the Middle East, and Southeast Asia, with strong domestic presence across all major industrial centers in India.Q: What benefits do your Gas Turbine Filters offer for industrial applications?

A: These filters provide high dust holding capacity, excellent efficiency (up to 99.97%), low maintenance, and are engineered for long service life, making them suitable for demanding industrial and utility-scale applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

Hydraulic Replacement Oil Filter

Efficiency (%) : Up to 99%

Cleaning Method : Other, Replaceable

Shape : Cylinder

Medium Filter : Other, Hydraulic Oil

Construction : Other, Cylindrical, Welded structure

Media Type : Other, Fiberglass & Stainless steel mesh

Hydraulic Oil Filter for Concrete pump

Efficiency (%) : 98%

Cleaning Method : Other, Washable / Replaceable

Shape : Cylindrical

Medium Filter : Other, Hydraulic Oil

Construction : Other, Cylindrical, Welded Seam

Media Type : Other, Wire mesh & stainless steel fiber

Hydraulic Suction Filter

Efficiency (%) : Up to 98%

Cleaning Method : Other, Washable/Reusable

Shape : Cylindrical

Medium Filter : Other, Hydraulic Oil

Construction : Other, Round cylindrical body with threaded end cap

Media Type : Other, Liquid

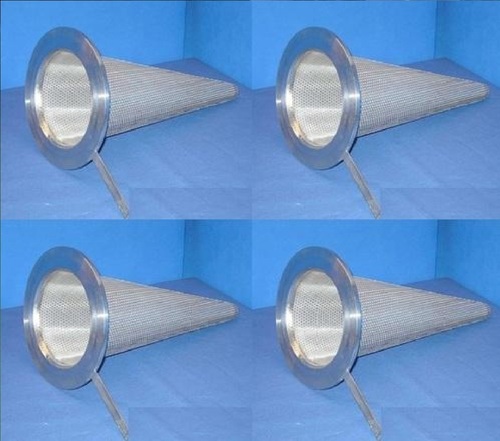

Sintered Mesh Cone Filter

Efficiency (%) : Up to 99.9%

Cleaning Method : Other, Backwash, Ultrasonic, Solvent Cleaning

Shape : Cone

Medium Filter : Other, Liquid, Gas

Construction : Other, Sintered multilayer mesh cone

Media Type : Other, Sintered wire mesh

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free