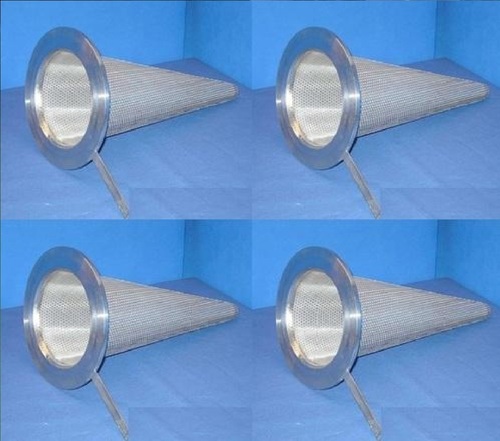

Sintered Mesh Cone Filter

Sintered Mesh Cone Filter Specification

- Cleaning Method

- Backwash, Ultrasonic, Solvent Cleaning

- Filtration Grade

- High / SS Sintered

- Efficiency (%)

- Up to 99.9%

- Temperature Range

- -50C to 500C

- Connecting Type

- Welded or Threaded

- Flow Rate

- Customizable, typically 5-50 L/min

- Filter Type

- Cone Type / Cartridge

- Media Type

- Sintered wire mesh

- Pressure

- Up to 10 bar

- Capacity

- Custom or up to 10 m/h

- Condition

- New

- Material

- Stainless Steel (SS304/SS316L)

- Mesh

- Woven wire mesh, multiple layers

- Diameter

- Custom, typically 30 mm 150 mm

- Construction

- Sintered multi-layer mesh cone

- Medium Filter

- Liquid, Gas

- Weight

- Depends on size, approx. 70-300 grams

- Shape

- Cone

- Feature

- High dirt-holding capacity, uniform pore size distribution, robust structure

Sintered Mesh Cone Filter Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Sintered Mesh Cone Filter

- Category:Filter Strainer

- Material:Stainless Steel 304,316,202 or as per your request.

- Properties:Filter Strainer

- Application:

- Distillation,

- Absorption,

- Evaporation and Filtration Process of Rubber,

- Plastic Industry,

- The Screening of Grain and Oil

- tag:

- Sintered Mesh,

- Cone Filter,

- Stainless Steel,

Engineered for Demanding Applications

The sintered mesh cone filter excels in challenging environments, providing reliable filtration for liquids and gases in oil & gas, chemical, pharmaceutical, petrochemical, and food & beverage industries. Its robust stainless steel construction ensures long-lasting performance even under high-pressure or corrosive conditions.

Customizable for Your Precise Needs

With customizable diameter, micron rating, flow rate, and end connections, these filters can be adapted to suit a broad range of industrial processes. Choose from threaded, welded, flanged, or custom connections to match your system requirements seamlessly.

Unmatched Filtration Performance and Efficiency

With uniform pore size distribution, a high dirt-holding capacity, and up to 99.9% filtration efficiency, the multi-layered filter media ensures consistent performance. The washable and reusable design reduces maintenance costs and environmental impact, making it a sustainable choice for ongoing operations.

FAQs of Sintered Mesh Cone Filter:

Q: How does the sintered mesh cone filter achieve such high filtration efficiency?

A: The filter utilizes several layers of woven stainless steel mesh sintered together, which ensures uniform pore size distribution and reliable particle retention. This multi-layer construction enables filtration efficiencies of up to 99.9%, even with fine micron ratings between 1 and 200 microns.Q: What cleaning methods can be used to maintain the filters reusability?

A: You can clean the sintered mesh cone filter using backwash, ultrasonic cleaning, or solvent cleaning methods. These approaches effectively remove contaminants without compromising the filters structural integrity, allowing for multiple reuses and extended service life.Q: When is it advisable to use the sintered mesh cone filter in industrial operations?

A: This filter is ideal in scenarios requiring high dirt-holding capacity and reliable filtration under harsh or corrosive conditions, such as in oil & gas, chemical processing, pharmaceuticals, petrochemicals, and food & beverage production. Its robust structure and corrosion resistance make it suitable for both liquid and gas applications.Q: Where can the filter be installed within a filtration system?

A: Sintered mesh cone filters are typically installed in pipeline filtration systems at critical points where fine particulate removal is necessary. Their customizable end connections (male, female, flange, or bespoke) allow them to integrate seamlessly into various equipment or process lines.Q: What are the benefits of choosing a sintered mesh cone filter over traditional filter elements?

A: Compared to conventional filters, sintered mesh cone filters offer excellent corrosion resistance, high pressure and temperature tolerance, long service life, and consistent filtration results. Their washable and reusable nature reduces operation costs and environmental impact.Q: How is the filter tailored to meet specific application requirements?

A: You can specify details such as micron rating, diameter (typically 30150 mm), thickness, flow rate, and end connection type. OEM services are available to ensure precise alignment with your operational needs and standards like ASTM, DIN, or IS.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

Anti Static Cartridge Filter

Medium Filter : Other, Synthetic Fiber

Efficiency (%) : 99%

Construction : Other, Cylindrical

Condition : New

Filtration Grade : Other, Industrial

Mesh : Pleated Media

Lube Oil Filters

Medium Filter : Other, Lube Oil

Efficiency (%) : Up to 99%

Construction : Other, Cartridge Type

Condition : New

Filtration Grade : Other, Medium to Fine

Mesh : 5 to 40 Micron

8 Micron Hydraulic Filter

Medium Filter : Other, Hydraulic Oil

Efficiency (%) : 99%

Construction : Other, Cartridge Type

Condition : New

Filtration Grade : Other, Medium

Mesh : 8 Micron

CONICAL FILTER CARTRIDGE

Medium Filter : Other, Liquid, Gas and Air

Efficiency (%) : Up to 99%

Construction : Other, Seamless welded construction

Condition : New

Filtration Grade : Other, Industrial

Mesh : Available in different micron ratings

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS