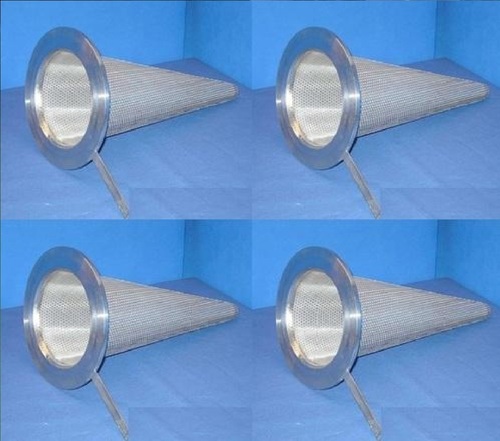

Hydraulic Oil Filter for Concrete pump

Hydraulic Oil Filter for Concrete pump Specification

- Capacity

- Depend on model; standard 5-10 liters/min capacity

- Temperature Range

- -25C to +110C

- Filtration Grade

- Hydraulic

- Connecting Type

- Flanged / Threaded (Custom on Request)

- Flow Rate

- Up to 120 L/min

- Media Type

- Wire mesh & stainless steel fiber

- Cleaning Method

- Washable / Replaceable

- Pressure

- Maximum 210 bar (depends on pump model)

- Filter Type

- Return Line / Suction Line Hydraulic Filter

- Efficiency (%)

- 98%

- Condition

- New

- Material

- Stainless Steel

- Mesh

- Fine Mesh (customizable, typical 80-100 mesh)

- Diameter

- 110 mm (approx)

- Construction

- Cylindrical, Welded Seam

- Medium Filter

- Hydraulic Oil

- Weight

- 1.2 kg (approx)

- Shape

- Cylindrical

- Feature

- High dirt holding capacity, Corrosion resistance, Durable construction, Easy installation, Optimum performance

Hydraulic Oil Filter for Concrete pump Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Hydraulic Oil Filter for Concrete pump

Hydraulic Oil Filter for Concrete pumpWe are among the reputed names in the industry for supplying and trading Hydraulic Oil Filter. The offered hydraulic filter is installed in hydraulic systems for filtering minerals and contaminants through water. It is made from high quality metal by our renowned manufacturers. This filter is available at cost-effective prices.

Features:

Effective filtration

Reliable performance

Compact in size

Specifications:

OD-77 MM,Id-43mm,H-327MM

Protect Your Concrete Pumps Heart The Hydraulic System

Concrete pump operation depends on a well-maintained hydraulic system. This filter acts as the frontline defense, capturing contaminants and particles before they reach critical components. By maintaining optimal oil cleanliness, it prevents wear, reduces breakdowns, and directly contributes to longer equipment life and lower maintenance costs.

Versatile Compatibility for Industry-leading Brands

Designed to fit seamlessly with most major concrete pump brandsincluding Schwing, Putzmeister, and Sanythis hydraulic oil filter adapts to diverse equipment needs. Its flanged or threaded connection options, along with customizable mesh grades, ensure straightforward integration within existing setups, making it an ideal solution for exporters, manufacturers, and traders across India.

FAQs of Hydraulic Oil Filter for Concrete pump:

Q: How does the hydraulic oil filter benefit concrete pump operations?

A: The filter removes contaminants from the hydraulic oil, supporting optimum system efficiency and reducing wear on hydraulic components. This proactive filtration minimizes downtime, extends the equipments service life, and helps avoid costly repairs due to oil contamination.Q: What is the recommended replacement schedule for this filter?

A: It is suggested to replace the filter according to OEM recommendations or at least every 12 months. Actual replacement may depend on operational intensity and oil cleanliness, but not exceeding a service life of 6000 hours ensures optimal performance.Q: When should I clean or replace my hydraulic oil filter?

A: Check and clean the filter when routine maintenance is scheduled or if there is a noticeable drop in pump efficiency. If the filter is washable, follow the provided guidelines; otherwise, replace if excessive buildup or damage is detected, or as per the specified replacement period.Q: What is the process for installing the hydraulic oil filter?

A: Installation is straightforwarduse the supplied flange or threaded connection as suited to your hydraulic system. The cylindrical, welded construction allows for easy replacement or installation, and the gasket (NBR/Viton) ensures a secure, leak-proof seal every time.Q: Where can this filter be used and for which brands is it compatible?

A: This filter is suitable for concrete pumps from industry leaders such as Schwing, Putzmeister, and Sany, among others. It is designed for universal application across various hydraulic oil filtration points, including suction and return lines.Q: What is the benefit of a stainless steel mesh filter with a polished finish?

A: The stainless steel mesh provides excellent durability and corrosion resistance even under demanding operating conditions. The polished finish further enhances rust-proof properties, resulting in a long-lasting, low-maintenance filtration solution.Q: How efficient is the filter, and what is its flow capacity?

A: With a filtration efficiency of up to 98% and a flow rate of up to 120 L/min (depending on pump model), this filter ensures continuous, reliable hydraulic oil protectionprotecting your system at every discharge cycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

Sintered Mesh Cone Filter

Mesh : Woven wire mesh, multiple layers

Connecting Type : Other, Welded or Threaded

Medium Filter : Other, Liquid, Gas

Material : Stainless Steel (SS304/SS316L)

Media Type : Other, Sintered wire mesh

Filter Type : Cone Type / Cartridge

Heavy Duty Air Filter

Mesh : Fine Mesh

Connecting Type : Other, Clamp / Flange Type

Medium Filter : Other, Air

Material : Galvanized Steel Frame, Synthetic Filter Media

Media Type : Other, Synthetic Nonwoven / Pleated

Filter Type : Cartridge / Panel Type

Axial Seal HVAC Filters

Mesh : MultiLayer Synthetic Mesh

Connecting Type : Other, Axial Seal, Slipon Type

Medium Filter : Other, Yes

Material : Synthetic Fiber Media, Galvanized Iron Frame

Media Type : Other, Synthetic Fiber

Filter Type : Panel Filter, Axial Seal

Pleated Cartadge Filter

Mesh : Metal Mesh

Connecting Type : Other, Not specified in the image

Medium Filter : Other, Not specified in the image

Material : Metal Mesh Synthetic Fiber

Media Type : Other, Not specified in the image

Filter Type : Pleated Cartridge Filter

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS