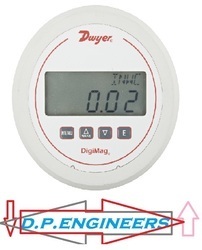

Digital Differential Pressure Gauges

Digital Differential Pressure Gauges Specification

- Sensor Type

- Piezoelectric & Strain Gauge Sensor

- Grade

- Industrial

- Seal Material

- Silicone Rubber

- Display

- Digital LCD

- Outer Size

- 110 mm x 60 mm x 40 mm

- Thread

- 1/4 NPT

- Material

- ABS Housing / Stainless Steel Ports

- Dial Material

- Polycarbonate

- Pointer Material

- Not Applicable (Digital)

- Processing Type

- Microcontroller Based

- Diameter

- 60 mm

- Glass Size

- 60 mm

- Mount Type

- Wall / Panel Mount

- Scale Range

- 0-1000 Pa, 0-5 kPa, 0-10 kPa (selectable)

- Accuracy

- 1% of Full Scale

- Finishing

- Powder Coated

- Measure Pressure Of

- Gas, Air, Non-corrosive Fluids

- Accessories

- Mounting Bracket, User Manual, Calibration Certificate

About Digital Differential Pressure Gauges

Applications:

- Bubbler Systems

- Laminar Flow Hoods

- Filter Status

- Duct Static Pressure

- Clean Room Pressure

- Building Pressure

- Fan Blower Pressure

- Paint Booths

- Dust Collectors

- Glove Box Pressure

- Cabinet Purging

| Maximum Pressure | 4 w.c. and less = 2 PSI; 5 w.c. and above = 10 PSI |

| Media compatibility | Air and compatible non combustible, non corrosive gasses |

| Accuracy | Axxx0-xx 1.00%; Axxx1-xx 0.50%; Axxx2-xx 0.25% |

| Temperature Ranges: Compensated and Operating | -10 to 140F (-23 to 60C) |

| Thermal Effect | +/- 0.012% FS/F |

| Output Signal | 4-20 mA (option) |

| Loop Resistance | 750 Max (for internally sourced power); 1800 Max (for externally sourced power of 36 VDC) |

| Power Supply | Universal 24-240 VAC or VDC |

| Housing Material | Glass Filled Nylon |

| Enclosure Rating | Designed to meet NEMA 4X face; with optional cover the entire product is weather proof |

Versatile Power and Output Options

This gauge supports both DC 24V and battery-powered modes, allowing for flexible installation in varied environments and reducing downtime due to power interruptions. It offers both analog 4-20mA and RS485 Modbus digital outputs, simplifying integration with modern control and monitoring systems.

High Precision and Industrial Durability

Engineered for demanding applications, the instrument features a 1% full-scale accuracy and a robust microcontroller-based design. Its ABS housing and stainless steel ports ensure longevity, and an IP54 ingress rating provides suitable protection for industrial settings.

User-Centric Features for Enhanced Usability

A clearly illuminated LCD with backlight, quick-response time, push-button zero adjustment, and easily adjustable high/low alarms make operation straightforward. Multiple mounting options (wall/panel), supplied calibration certificate, and user manual help streamline setup and everyday use.

FAQs of Digital Differential Pressure Gauges:

Q: How do I power the Digital Differential Pressure Gauge?

A: You can operate the gauge using either a DC 24V power supply or standard batteries. The selectable power modes provide flexibility based on your sites requirements and ensure uninterrupted operation during power fluctuations.Q: What types of outputs does the gauge offer for data integration?

A: This gauge is equipped with both analog output (4-20mA) and RS485 Modbus, enabling seamless integration into diverse industrial automation and monitoring systems for real-time data transmission.Q: Where can this gauge be installed and what mounting options are available?

A: The unit is designed for installation on wall or panel surfaces. It comes with a mounting bracket, making setup straightforward in industrial settings such as factories, laboratories, or HVAC systems.Q: How does the device ensure accurate readings and quick response?

A: With a high accuracy of 1% of full scale and a rapid response time of under 1 second, the gauge uses advanced piezoelectric and strain gauge sensors. A push-button zero adjustment allows for quick recalibration when needed.Q: What media are compatible for measurement with this gauge?

A: This device is suitable for measuring the differential pressure of gases, air, and other non-corrosive fluids, making it highly versatile for various industrial applications.Q: What benefits does the adjustable alarm function offer?

A: The high/low alarm settings provide immediate alerts if pressure readings stray outside your defined parameters, improving safety and helping prevent process disruptions.Q: Is the Digital Differential Pressure Gauge certified for industrial use?

A: Yes, it is CE marked, RoHS compliant, and built to industrial standards, ensuring reliable performance and adherence to global safety and environmental requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DWYER Magnehelic Gauge Category

Industrial Magnehelic Gauges

Grade : Industrial

Measure Pressure Of : Other, Air and Noncorrosive Gases

Mount Type : Other, Surface/Flush Mount

Sensor Type : Differential Pressure

Material : Other, Diecast Aluminum case

Finishing : Other, Powder Coated or Anodized

Magnehelic Gauge Sensor

Grade : Industrial Grade

Measure Pressure Of : Other, Air and Noncorrosive Gases

Mount Type : Other, Surface or Panel Mounting

Sensor Type : Differential Pressure Sensor

Material : Other, Diecast Aluminum housing

Finishing : Other, Powder Coated/Anodized finish

Dwyer Make Digital Differential Pressure Gauges

Grade : Industrial grade

Measure Pressure Of : Air or compatible gases, Other

Mount Type : Flush mount, Other

Sensor Type : Differential pressure sensor

Material : Plastic, Other

Finishing : Matte white, Other

Dwyer Air Velocity Sensors

Grade : Industrial

Measure Pressure Of : Other, Air flow velocity

Mount Type : Other, Wall / Duct Mount

Sensor Type : Air Velocity Sensor

Material : Other, ABS Plastic Housing, Stainless Steel Probe

Finishing : Other, Powder Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free