Industrial Magnehelic Gauges

Industrial Magnehelic Gauges Specification

- Grade

- Industrial

- Display

- Analog

- Seal Material

- Silicone Rubber

- Thread

- 1/8 NPT

- Outer Size

- 4 inches (standard)

- Bourdon Tube

- Not Applicable (Diaphragm-based)

- Sensor Type

- Differential Pressure

- Material

- Die-cast Aluminum case

- Dial Material

- Aluminum sheet with printed scale

- Pointer Material

- Plastic / Aluminum

- Processing Type

- Machined & Assembled

- Diameter

- 115 mm (approximate)

- Glass Size

- 100 mm

- Mount Type

- Surface/Flush Mount

- Scale Range

- 0-60 In. WC (custom ranges available)

- Accuracy

- 2% of Full Scale

- Finishing

- Powder Coated or Anodized

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting Screws, Pressure Connectors

Industrial Magnehelic Gauges Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Industrial Magnehelic Gauges

Industrial Magnehelic Gauges

We are the leading manufacturer and exporter of a quality tested assortment of Industrial Magnehelic Gauges. Our range is widely used in checking the automatic valves and gas-air ratio controls, further in medical equipment also to monitor blood and respiratory pressures. Besides it is used to measure the fan and blow pressures, liquid levels and pressures in fluidic systems. Operated by a diaphragm our product is low in cost and is available in different specifications ranging from 0-10, 0-25, 0-40, 0-50, 0-100 MM Wc , and 0- 60 pA, 0-250 pA.

Uses :

Used for high accuracy-guaranteed within 2% of full scale and for the wide choice of 81 models available to suit your needs precisely.

Specifications:

- Application: Industrial

- Indicating Pressure Reference: Electric Contact

- Function: Local Indication Type

Precision Monitoring for Industrial Environments

Designed specifically for HVAC, cleanrooms, and industrial process automation, this Magnehelic Differential Pressure Gauge delivers rapid, accurate readings of differential pressure in air and non-corrosive gases. Its sensitive diaphragm-based sensor responds instantly, enabling proactive maintenance and system optimization.

Reliable Construction and Flexible Installation

Encased in rugged die-cast aluminum with a powder-coated or anodized finish, this gauge is built for longevity and protection against harsh industrial conditions. Two rear-mounted 1/8 NPT connection ports and options for surface or flush mounting provide installation flexibility to suit varied applications.

Safety and Compliance Assured

This gauge is CE certified and engineered according to stringent industrial standards. Its IP66 enclosure safeguards the internals from dust and water, while externally accessible zero adjustment allows on-site recalibration without dismantling. Accessories like mounting screws and connectors are supplied for a hassle-free setup.

FAQs of Industrial Magnehelic Gauges:

Q: How do I install the Industrial Magnehelic Differential Pressure Gauge?

A: This gauge is designed for vertical mounting, either on a surface or flush within a panel. Use the included mounting screws and connect the two 1/8 NPT rear-mounted ports to your air or non-corrosive gas lines. Ensure the gauge is positioned upright and the connections are secure for accurate differential pressure readings.Q: What is the recommended usage of this gauge in HVAC and cleanrooms?

A: The gauge excels at monitoring filters, fan performance, and airflow within HVAC systems and cleanrooms. By providing instantaneous and precise pressure data, it helps maintain optimal air quality and ensures systems operate within required safety and efficiency parameters.Q: When should the zero adjustment feature be used?

A: The external zero adjustment should be utilized after installation or routine maintenance to calibrate the gauge and eliminate any baseline drift. This ensures that ongoing measurements remain accurate without the need to disassemble the device.Q: Where is this Magnehelic gauge most commonly applied?

A: It is widely used in industrial automation, air handling units, cleanroom environments, and HVAC installations where accurate differential pressure measurement between two points is crucial for system performance and safety.Q: What benefits does the IP66 enclosure protection provide?

A: IP66 protection ensures the gauge is dust-tight and shielded against powerful water jets. This level of enclosure protection prolongs the operational life of the gauge, even in challenging environmental conditions encountered in industrial and cleanroom applications.Q: How can I ensure optimal performance and accuracy of the gauge?

A: Install the gauge in its designated vertical orientation, use compatible mounting hardware, and regularly verify zero adjustment. Ensure that only air or non-corrosive gases are measured, and keep the enclosure clean to maintain IP66 protection. Periodic calibration is recommended to uphold 2% full scale accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DWYER Magnehelic Gauge Category

Magnehelic Differential Pressure Gauge India - DWYER - D.P.ENGINEERS DELHI NCR

Price 6500 INR / Piece

Minimum Order Quantity : 50 Pieces

Mount Type : Back

Pointer Material : Aluminum

Measure Pressure Of : Steam, Oil, Gas

Finishing : Antique, Polished, Galvanized, Matte

Series 2000 DWYER MAGNEHELIC Differential Pressure Gauges for Firozabad Uttar Pradesh

Price 7500 INR / Piece

Minimum Order Quantity : 20 Pieces

Mount Type : Back

Pointer Material : Alloy

Measure Pressure Of : Steam, Oil, Gas

Finishing : Matte, Polished, Galvanized, Antique

Magnehelic Gauge Sensor

Mount Type : Other, Surface or Panel Mounting

Pointer Material : Other, Redfinished Aluminum

Measure Pressure Of : Other, Air and Noncorrosive Gases

Finishing : Other, Powder Coated/Anodized finish

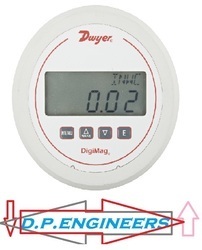

Dwyer Make Digital Differential Pressure Gauges

Mount Type : Flush mount, Other

Pointer Material : Other, N/A (No physical pointer)

Measure Pressure Of : Air or compatible gases, Other

Finishing : Matte white, Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS