Magnehelic Gauge Sensor

Magnehelic Gauge Sensor Specification

- Thread

- 1/8 NPT Female

- Sensor Type

- Differential Pressure Sensor

- Display

- Analog Dial Display

- Outer Size

- Standard 4 (101 mm) diameter

- Grade

- Industrial Grade

- Seal Material

- Neoprene Gasket

- Material

- Die-cast Aluminum housing

- Dial Material

- High-Contrast Printed Aluminum

- Pointer Material

- Red-finished Aluminum

- Processing Type

- Factory Calibrated

- Diameter

- Approx. 4 inches (101 mm)

- Glass Size

- Full Face Clear Acrylic

- Mount Type

- Surface or Panel Mounting

- Scale Range

- 0-60 Pascal (custom ranges available)

- Accuracy

- 2% of Full Scale

- Finishing

- Powder Coated/Anodized finish

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting Screws, Rubber Grommets, Instruction Manual

Magnehelic Gauge Sensor Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Magnehelic Gauge Sensor

Magnehelic Gauge Sensor

Admired as first among the best,we provide clients with the premium quality of Magnehelic Gauge Sensor. The gauge sensor is used for air velocity monitoring applications and is manufactured by using latest technology. By following total quality management, the quality of Magnehelic gauge sensor is never compromised.

Features:

Excellent air velocity monitoring efficiency

- Compact design

- Easy to operate and maintain

Specifications:

- Type: Piezoresistive Pressure Sensor

- Component: Mechanical Structure Type

- For: Strain Gauge Pressure Transmitter

- Output Signal Type: Digital Type

Accurate and Durable Performance

Engineered for precision, the Magnehelic Gauge Sensor is factory-calibrated for 2% full-scale accuracy, ensuring dependable results in demanding environments. Its robust die-cast aluminum construction and clear full-face acrylic glass protect the mechanism while maintaining high visibility of the analog dial. The external zero adjustment knob provides easy calibration even during operation.

Versatile Applications Across Industries

The sensor is well-suited for a variety of environments, including HVAC systems, clean rooms, laboratory settings, industrial processes, and filter monitoring. It measures the differential pressure of air and non-corrosive gases, making it a critical tool for maintaining optimal environmental conditions and operational efficiency.

User-Friendly Design and Easy Installation

Featuring a standard 4-inch diameter and 1/8 NPT female thread, this gauge is designed for both surface and panel mounting. It comes complete with mounting screws, rubber grommets, and a detailed instruction manual. The externally adjustable zero knob and immediate analog response facilitate quick setup and ongoing adjustments as required.

FAQs of Magnehelic Gauge Sensor:

Q: How does the Magnehelic Gauge Sensor measure differential pressure?

A: The sensor utilizes a precision diaphragm and mechanical linkage to detect and display the pressure difference between two points, using an analog dial display for real-time readings of air and non-corrosive gases.Q: What is the process for installing the gauge in an HVAC or laboratory setting?

A: Installation requires mounting the gauge using the provided screws and rubber grommets, connecting the 1/8 NPT female threaded ports to the pressure lines, and adjusting the zero setting using the external knob for calibration.Q: When should I use external zero adjustment on this gauge?

A: External zero adjustment is typically used before or during operation to calibrate the reference reading, ensuring accurate differential pressure measurement after installation or following maintenance.Q: What are the benefits of using a factory-calibrated, analog Magnehelic Gauge Sensor?

A: Factory calibration ensures high accuracy (2% of full scale) out of the box, reducing setup time, and the analog dial offers immediate, continuous visual feedback, which is ideal for real-time monitoring and fast troubleshooting.Q: Where can this gauge be applied within industrial and laboratory operations?

A: It is extensively used for monitoring pressure in HVAC systems, clean room environments, laboratory air filtration, industrial process control, and filter status checks, wherever precise differential pressure monitoring is required.Q: How is the durability of the sensor ensured in harsh environments?

A: The sensor features a die-cast aluminum housing, powder-coated or anodized finish for corrosion resistance, neoprene gaskets for airtight sealing, and a full-face clear acrylic glass for impact protection, ensuring long-term reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DWYER Magnehelic Gauge Category

Series 2000 DWYER MAGNEHELIC Differential Pressure Gauges for Firozabad Uttar Pradesh

Price 7500 INR / Piece

Minimum Order Quantity : 20 Pieces

Mount Type : Back

Processing Type : Standard

Material : Metal Alloy

Measure Pressure Of : Steam, Oil, Gas

Industrial Magnehelic Gauges

Mount Type : Other, Surface/Flush Mount

Processing Type : Other, Machined & Assembled

Material : Other, Diecast Aluminum case

Measure Pressure Of : Other, Air and Noncorrosive Gases

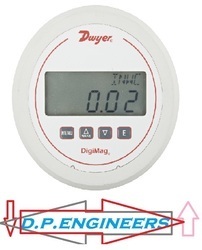

Dwyer Make Digital Differential Pressure Gauges

Mount Type : Flush mount, Other

Processing Type : Other, Digital processing

Material : Plastic, Other

Measure Pressure Of : Air or compatible gases, Other

Dwyer Air Velocity Sensors

Mount Type : Other, Wall / Duct Mount

Processing Type : Other, Precision Sensor Assembly

Material : Other, ABS Plastic Housing, Stainless Steel Probe

Measure Pressure Of : Other, Air flow velocity

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free